A preparation method of liquid-phase silicon-assisted forming thermal protection z-pins silicide ceramic rod structure

A technology of silicide and ceramic rod, which is applied in the field of preparation of liquid-phase silicon-assisted forming thermal protection Z-pins silicide ceramic rod structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

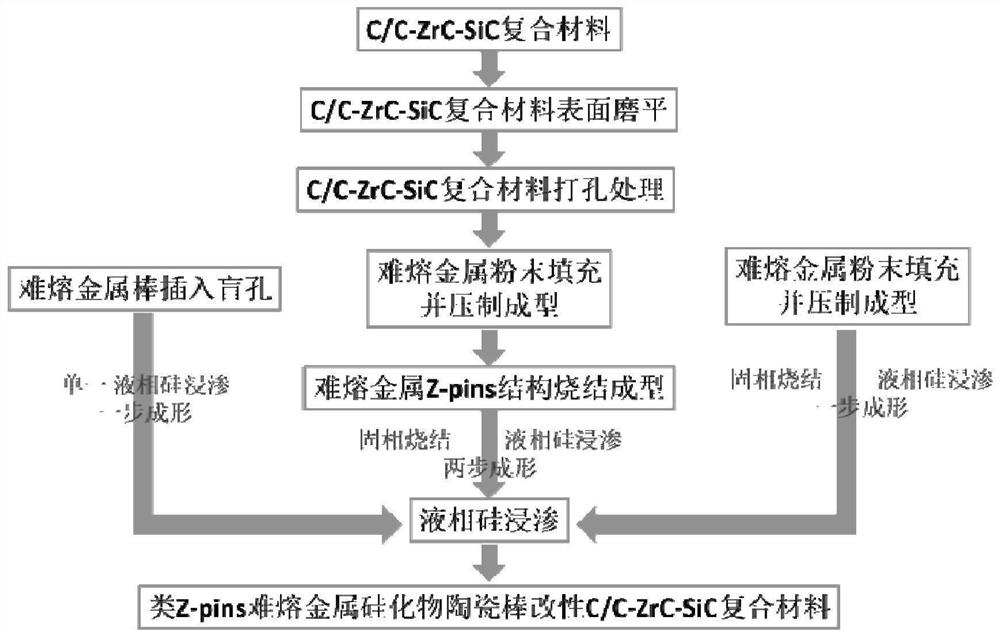

Method used

Image

Examples

Embodiment 1

[0140] 2) For a thickness of 10mm and a diameter of The cylinder of C / C-ZrC-SiC composite material is punched; the punching equipment adopts a vertical machining center (JASU V-850); the hole diameter is 2.0mm, the hole depth is 6mm, and the number of holes is 29. The distribution density is 10%.

[0141] 2) Pretreat the refractory metal vanadium powder and high-purity carbon powder; select refractory metal vanadium powder with a particle size of 50 μm and a purity greater than 99.9% (Beijing Xingrongyuan Technology Co., Ltd.), high-purity carbon powder 10 %, particle size 100nm purity greater than 99.99% (Beijing Rongyuan Technology Co., Ltd.), the added high-purity carbon powder is 10% of the total metal powder atomic ratio, and the selected powder is added with 5% liquid paraffin as a forming agent (Sinopharm Group Chemical Reagent Co., Ltd.), pour absolute ethanol as the ball milling medium, use a planetary ball mill to wet-grind the metal powder and liquid paraffin unde...

Embodiment 2

[0162] 3) For a thickness of 10mm and a diameter of The cylinder of C / C-ZrC-SiC composite material is punched; the punching equipment adopts a vertical machining center (JASU V-850); the hole diameter is 2.0mm, the hole depth is 6mm, and the number of holes is 29. The distribution density is 10%.

[0163] 2) Pretreat the refractory metal vanadium powder; select the powder with a particle size of 50 μm and a purity greater than 99.9% (Beijing Xingrongyuan Technology Co., Ltd.); and add 2% liquid paraffin to the selected powder as a forming agent (Sinopharm Group Chemical Reagent Co., Ltd.), pour absolute ethanol as the ball milling medium, use a planetary ball mill to wet-grind the metal powder and liquid paraffin under the protection of argon for 12 hours until uniform, and then dry it in a vacuum oven for 12 hours before use;

[0164] 3) Manually filling the prepared refractory metal vanadium powder into the blind hole of the substrate and compacting it;

[0165] 4) Put th...

Embodiment 3

[0175] 4) For a thickness of 10mm and a diameter of The cylinder of C / C-ZrC-SiC composite material is punched; the punching equipment adopts a vertical machining center (JASU V-850); the hole diameter is 2.0mm, the hole depth is 6mm, and the number of holes is 29. The distribution density is 10%.

[0176] 2) Pretreat the refractory metal zirconium powder; select the powder with a particle size of 50 μm and a purity greater than 99.9% (Beijing Xingrongyuan Technology Co., Ltd.); and add 5% liquid paraffin to the selected powder as a forming agent (Sinopharm Group Chemical Reagent Co., Ltd.), pour absolute ethanol as the ball milling medium, use a planetary ball mill to wet-grind the metal powder and liquid paraffin under the protection of argon for 12 hours until uniform, and then dry it in a vacuum oven for 12 hours before use;

[0177] 3) Manually filling the prepared refractory metal zirconium powder into the blind hole of the substrate and compacting it;

[0178] 4) Putt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com