Slurry with mosquito repelling effect, polyurethane synthetic leather and preparation method of polyurethane synthetic leather

A polyurethane and synthetic leather technology, applied in textiles and papermaking, etc., can solve problems such as low efficiency, limited surface of synthetic leather, adverse effects, etc., and achieve the effects of increasing retention, improving agglomeration, and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

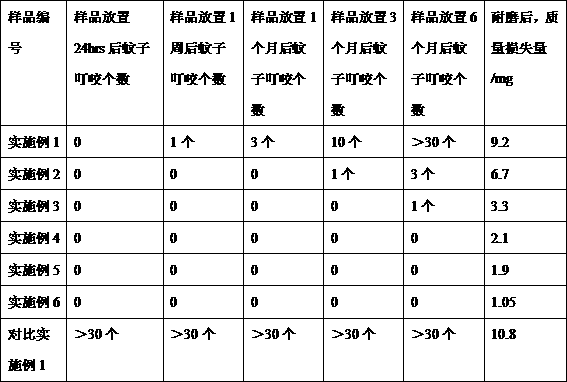

Examples

Embodiment 1

[0057] DEET slow-release mosquito repellent, (mass parts):

[0058] Polyurethane resin JF-S-8030: 100 parts

[0060] Silicon-based mesoporous material (MCM-41): 1 part

[0061] Cis-13-docosenoic acid amide: 0.2 parts

[0062] Mix the above-mentioned components, then stir for 60 minutes under the condition of 100 rpm, and then grind once on a three-roll mill to obtain DEET slow-release mosquito repellent;

[0063] Slurry:

[0064]Polyurethane resin JF-S-8030: 100 parts

[0065] Carbon black: 1 part

[0066] DEET slow-release mosquito repellent: 0.01 parts

[0067] (1) Stir the above-mentioned components evenly, prepare a slurry, coat the slurry on DE-178 release paper, and dry it at 100°C to obtain a polyurethane coating film with mosquito repellent effect;

[0068] (2) On the polyurethane coating film obtained in step (1), coat a layer of adhesive layer of JF-A-WV2010 resin, paste microfiber synthetic leather base cloth, dry at 40°C, peel...

Embodiment 2

[0070] IR3535 slow-release mosquito repellent, (mass parts):

[0071] Polyurethane resin JF-S-8030: 100 parts

[0072] IR3535: 500 copies

[0073] Silicon-based mesoporous material (KIT 6): 100 parts

[0074] Cetyltrimethylammonium bromide: 100 parts

[0075] The above components are mixed, then stirred for 30 minutes under the condition of 600 rpm, and then ground once on a three-roll mill to obtain the IR3535 slow-release mosquito repellent.

[0076] Slurry:

[0077] Polyurethane resin JF-S-8030: 100 parts

[0078] Dimethyl sulfoxide: 80 parts

[0079] Carbon black: 5 parts

[0080] IR3535 Slow Release Mosquito Repellent: 0.5 parts

[0081] (1) Stir the above components evenly, prepare a slurry, coat the slurry on DE-178 release paper, and dry it at 130°C to obtain a polyurethane coating film with mosquito repellent effect;

[0082] (2) Coat a layer of JF-A-WV2010 resin adhesive layer on the polyurethane coating film obtained in step (1), paste the microfiber synthet...

Embodiment 3

[0084] Picaridin sustained-release mosquito repellent, (mass parts):

[0085] Polyurethane resin JF-S-8030: 100 parts

[0086] Picardin: 300 servings

[0087] Silicon-based mesoporous material (NKF-11): 80 parts

[0088] Polyvinylpyrrolidone: 40 parts

[0089] The above components are mixed, then stirred at 400 rpm for 20 minutes, and then ground once on a three-roll mill to obtain the picaridin sustained-release mosquito repellent.

[0090] Slurry:

[0091] Polyurethane resin JF-S-8030: 100 parts

[0092] Butyl acetate: 40 parts

[0093] Acetone: 30 parts

[0094] Carbon black: 10 parts

[0095] Picaridin Extended Release Mosquito Repellent: 2 servings

[0096] (1) Stir the above components evenly, prepare a slurry, coat the slurry on DE-178 release paper, and dry it at 150°C to obtain a polyurethane coating film with mosquito repellent effect;

[0097] (2) Coat a layer of JF-A-WV2010 resin bonding layer on the polyurethane coating film obtained in step (1), paste th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com