Preparation method of fermented soya-bean milk

A technology of bean juice and soaking beans, which is applied in the preparation of fermented beans - old Beijing bean juice, and in the field of fermented bean products. The effect of shortening the fermentation time, good palatability, and slightly sour taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

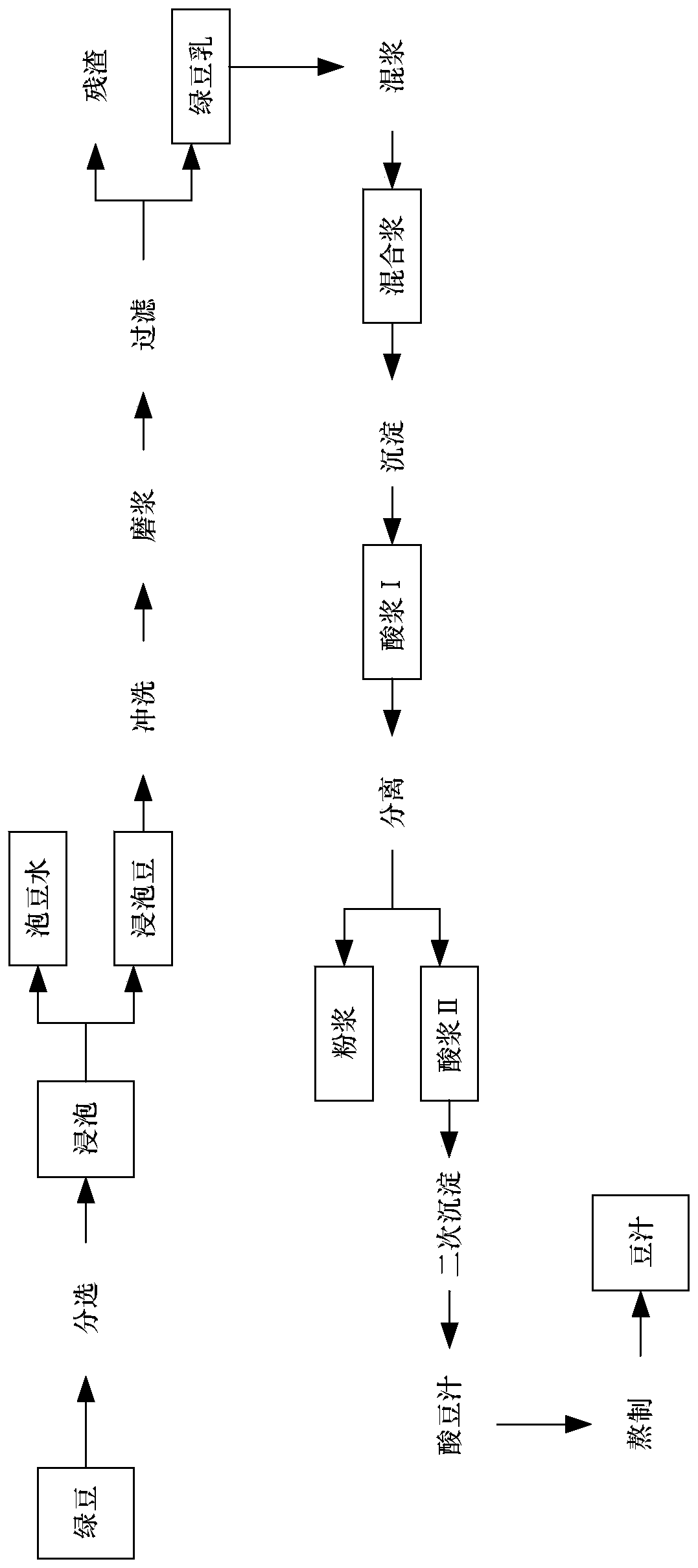

Method used

Image

Examples

preparation example Construction

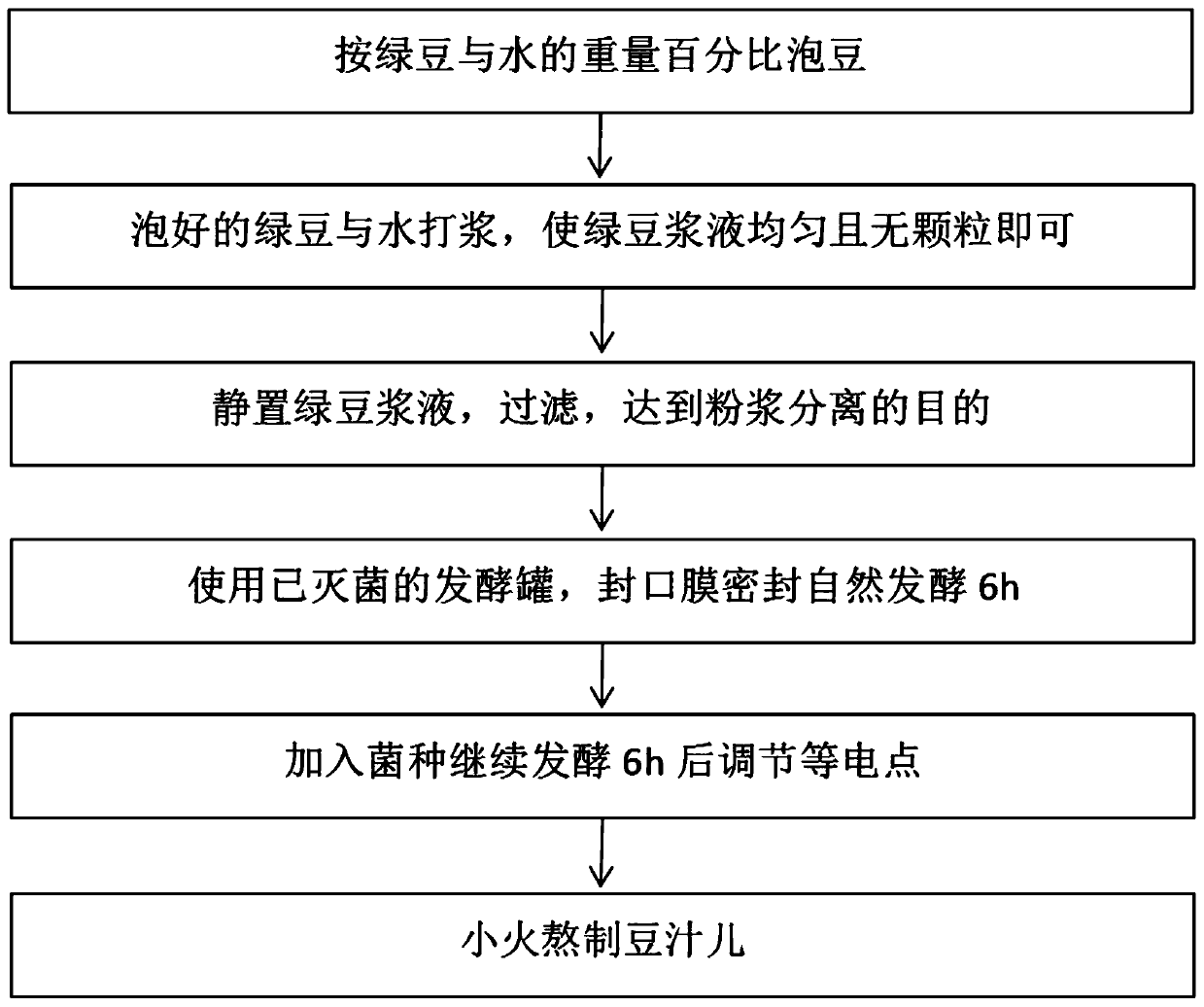

[0031] The preparation method of a kind of fermented bean of the present invention - Old Beijing Douzhi comprises the following steps:

[0032] Step 1, soak beans;

[0033] Soaking beans: at room temperature, soak the washed mung beans and water at a ratio of 1:8 by weight for 10-15 hours, and there is no need to change the amount of water in subsequent operations;

[0034] In the present invention, "no need to change the amount of water in the follow-up operation", on the one hand, it can ensure that the ingredients in the original soaked bean water, such as amino acids, are not lost, and on the other hand, it can also avoid the uneven texture of the mung bean slurry caused by the addition of water in the later stage. To a certain extent, the stratification phenomenon of soybean juice is improved.

[0035] Step 2, beating;

[0036] Beating: Pour the soaked mung beans and water into the beater and beat for 5-10 minutes to get a uniform mung bean slurry until there are no par...

Embodiment 1

[0049] use as figure 2 The process shown in the process of processing fermented mung beans - old Beijing bean juice

[0050] Step 1, soak beans;

[0051] Soaking beans: Soak the washed mung beans and water at a ratio of 1:8 by weight for 15 hours at 22°C, and there is no need to add water in subsequent operations;

[0052] Step 2, beating;

[0053] Beating: Pour the soaked mung beans and water into the Joyoung brand soybean milk machine. After beating for 5 minutes, pour it into an open glass bowl to get a uniform mung bean slurry until there are no particles;

[0054] Step 3, static filtration;

[0055] Static filtration: After standing the mung bean slurry in an open glass bowl for 45 minutes, take the supernatant and filter to complete the powder-slurry separation operation, and obtain the filtered slurry;

[0056] Step 4, natural fermentation;

[0057]Natural fermentation: Pour the filtered slurry into a sterilized fermenter, seal it with a parafilm and place it in a...

Embodiment 2

[0073] use as figure 2 The process shown in the process of processing fermented mung beans - old Beijing bean juice

[0074] Step 1, soak beans;

[0075] Soaking beans: Soak the washed mung beans and water at a ratio of 1:8 by weight for 10 hours at 26°C, and do not need to add water in subsequent operations;

[0076] Step 2, beating;

[0077] Beating: Pour the soaked mung beans and water into the Joyoung brand soybean milk machine. After beating for 3 minutes, pour it into an open glass bowl to get a uniform mung bean slurry until there are no particles;

[0078] Step 3, static filtration;

[0079] Static filtration: After standing the mung bean slurry in an open glass bowl for 30 minutes, take the supernatant and filter to complete the powder-slurry separation operation, and obtain the filtered slurry;

[0080] Step 4, natural fermentation;

[0081] Natural fermentation: Pour the filtered slurry into a sterilized fermenter, seal it with a parafilm and place it in a con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com