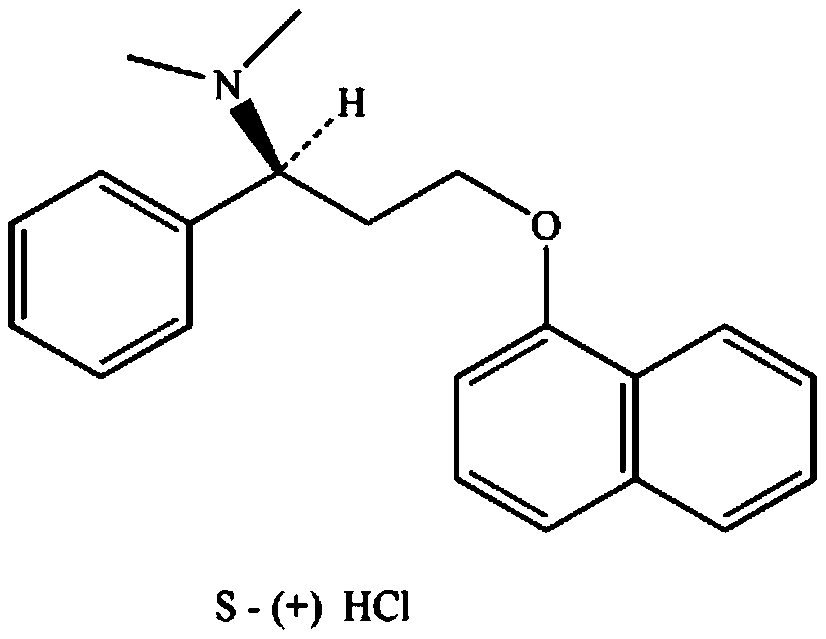

Dapoxetine hydrochloride tablet and preparation method thereof

A technology for dapoxetine hydrochloride and cetine tablets, which can be applied in the fields of pill delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., and can solve problems such as complex preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

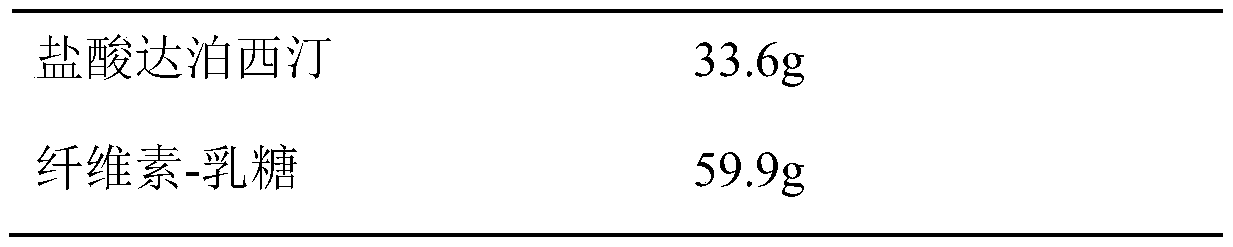

[0017] prescription

[0018]

[0019]

[0020] Preparation Process:

[0021] ①Pretreatment: Put dapoxetine hydrochloride in a high-efficiency pulverizer to pulverize through a 0.6mm sieve, and colloidal silica through a 24-mesh sieve for treatment. ② Mixing: Mix dapoxetine hydrochloride, cellulose-lactose, croscarmellose sodium, and colloidal silicon dioxide for 5 minutes first, then add magnesium stearate, and mix for another 1 minute. ③ Tabletting: Compress the mixed powder into tablets. ④ Coating: adding the coating powder into purified water to prepare a coating liquid with a solid content of 12%, and then coating, the weight of the coating increases by 3-4%. ⑤Aluminum / plastic / aluminum packaging: the coated tablets are packaged in aluminum / plastic / aluminum.

Embodiment 2

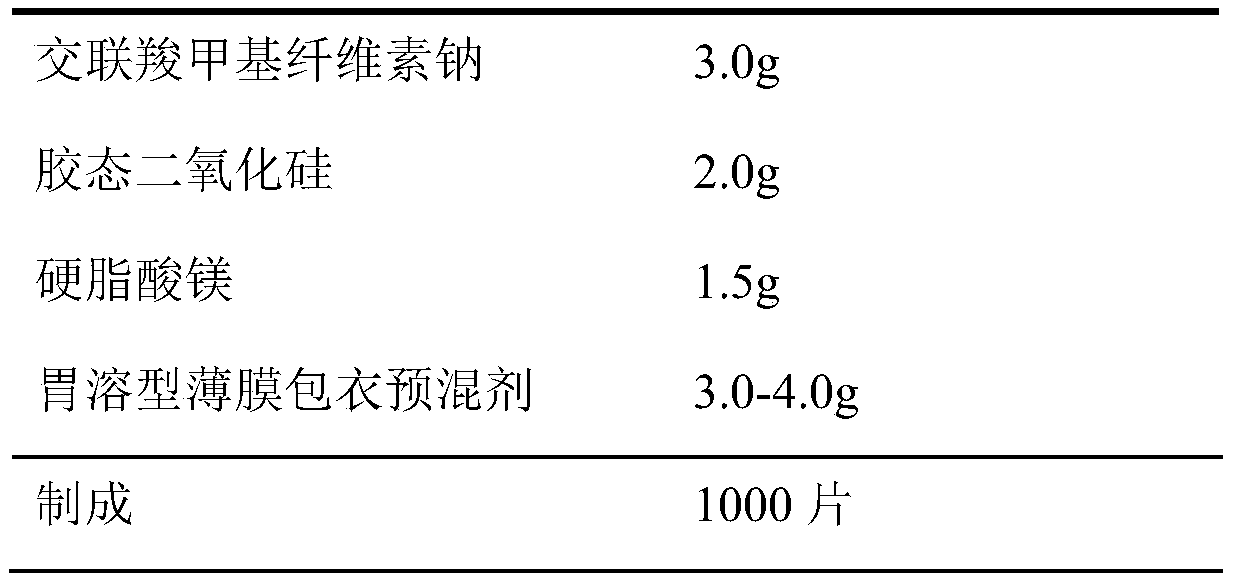

[0023] prescription

[0024]

[0025] Preparation Process:

[0026] ①Pretreatment: Put dapoxetine hydrochloride in a high-efficiency pulverizer to pulverize through a 0.6mm sieve, and colloidal silica through a 24-mesh sieve for treatment. ② Mixing: Mix dapoxetine hydrochloride, cellulose-lactose, sodium carboxymethyl starch, and colloidal silicon dioxide for 5 minutes first, then add magnesium stearate, and mix for another 1 minute. ③ Tabletting: Compress the mixed powder into tablets. ④ Coating: adding the coating powder into purified water to prepare a coating liquid with a solid content of 12%, and then coating, the weight of the coating increases by 3-4%. ⑤Aluminum / plastic / aluminum packaging: the coated tablets are packaged in aluminum / plastic / aluminum.

Embodiment 3

[0028] prescription

[0029]

[0030] Preparation Process:

[0031] ①Pretreatment: Put dapoxetine hydrochloride in a high-efficiency pulverizer to pulverize through a 0.6mm sieve, and colloidal silica through a 24-mesh sieve for treatment. ② Mixing: Mix dapoxetine hydrochloride, cellulose-lactose, croscarmellose sodium, and colloidal silicon dioxide for 5 minutes first, then add magnesium stearate, and mix for another 1 minute. ③ Tabletting: Compress the mixed powder into tablets. ④ Coating: adding the coating powder into purified water to prepare a coating liquid with a solid content of 12%, and then coating, the weight of the coating increases by 3-4%. ⑤Aluminum / plastic / aluminum packaging: the coated tablets are packaged in aluminum / plastic / aluminum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com