Manufacturing process of vacuum cup

A technology of vacuum insulation and manufacturing technology, which is applied in the direction of manufacturing tools, metal processing equipment, laser welding equipment, etc., can solve the problems of many welding procedures for thermos cups, pollute the environment, increase the manufacturing cost of thermos cups, etc., and achieve good heat preservation effect, High welding efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

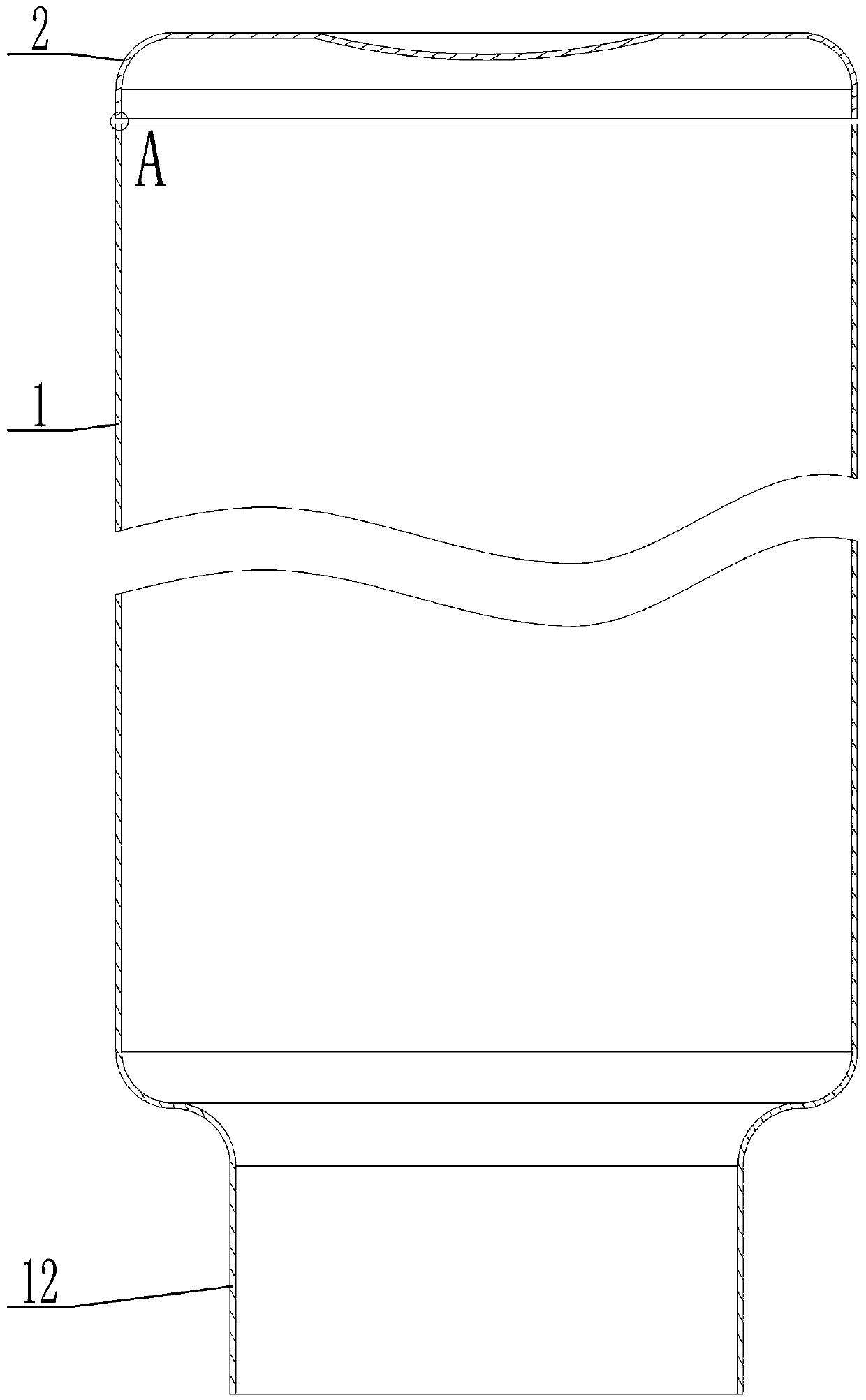

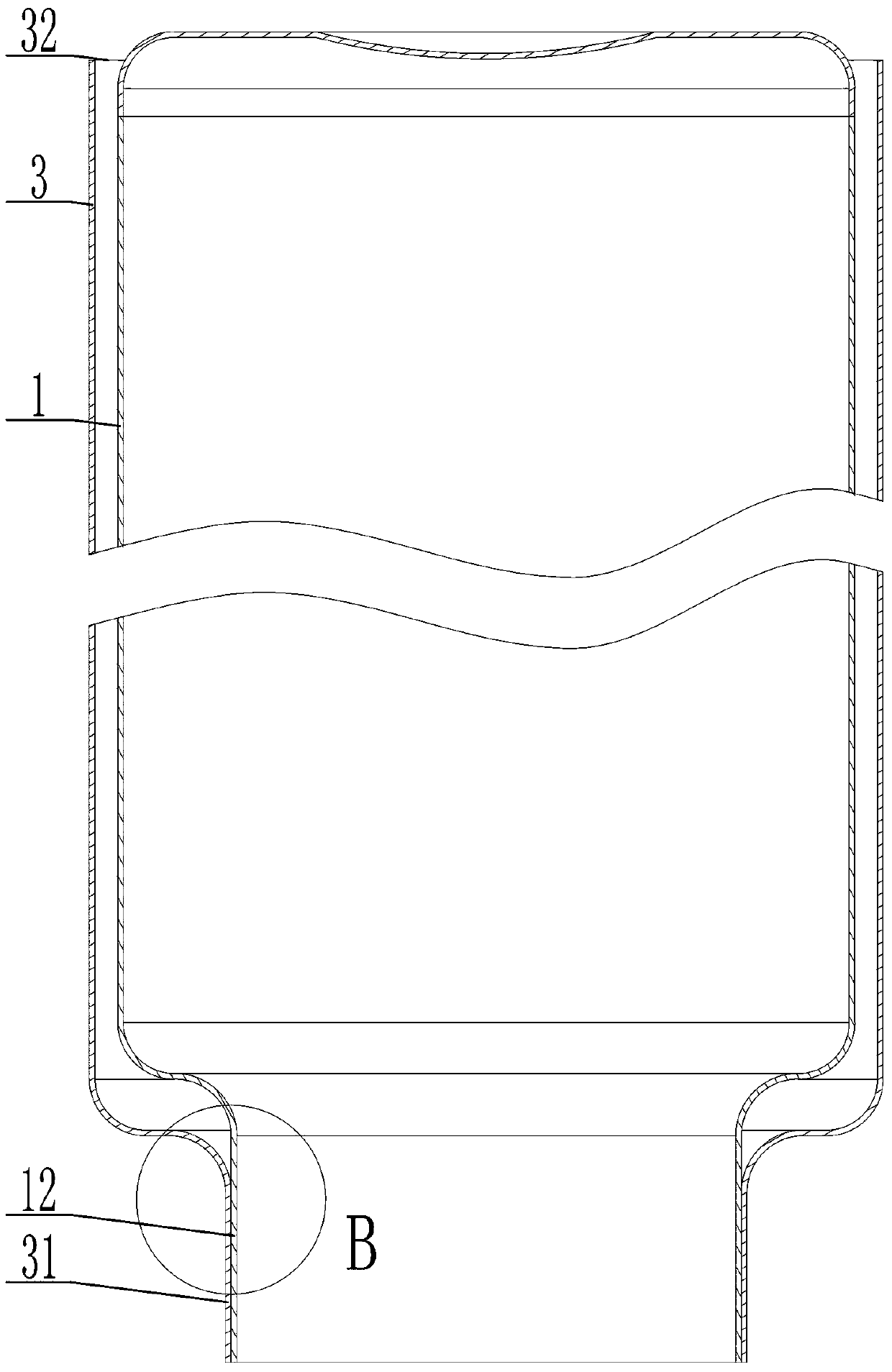

[0035] Such as Figure 1 to Figure 6 As shown, a manufacturing process of a vacuum insulation cup includes the following steps:

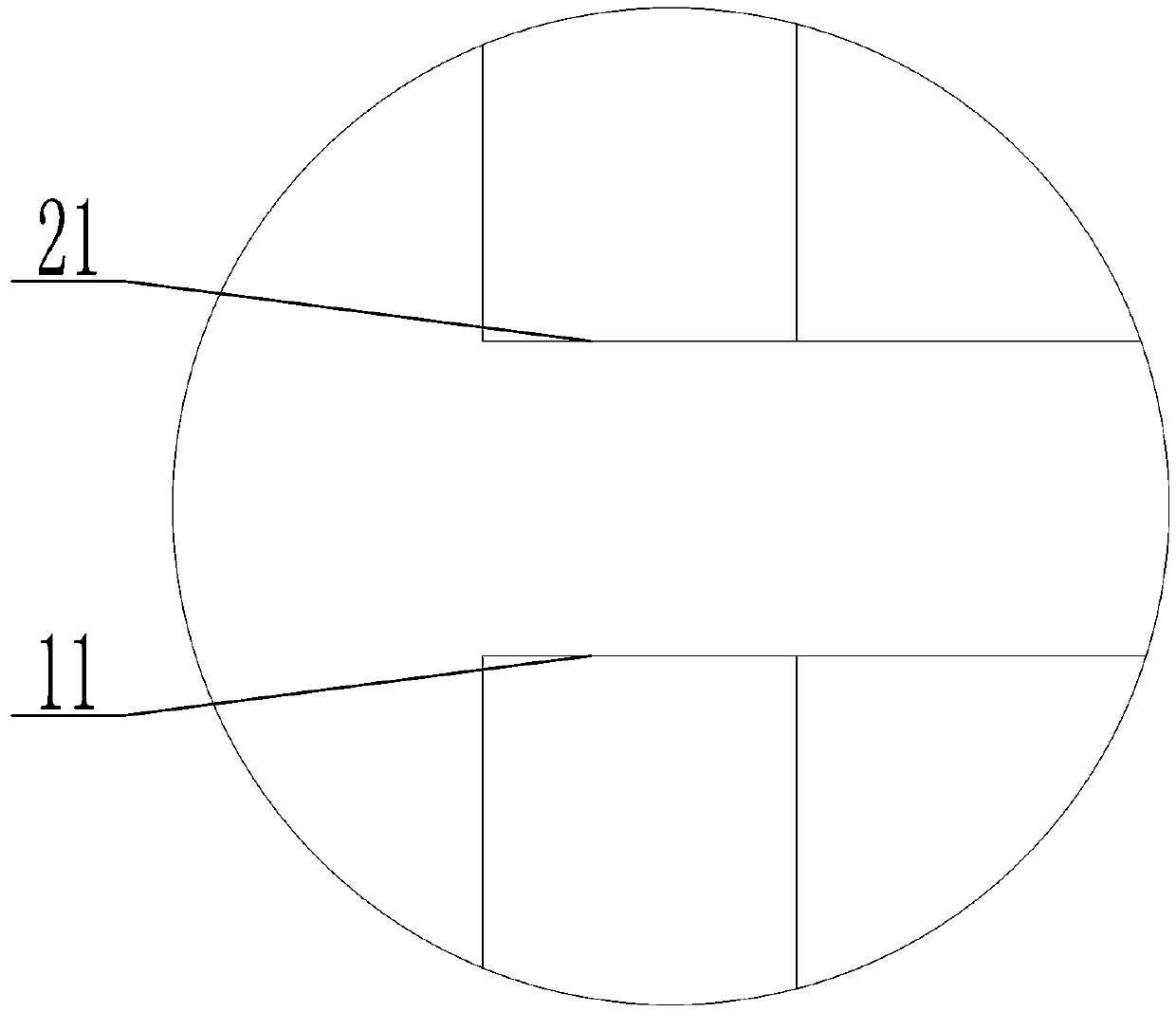

[0036] a. Take the liner cup body 1 and the liner bottom cover 2, and match the bottom surface 11 of the liner cup body with the end surface 21 of the liner bottom cover, and use a laser welding machine or an argon arc welding machine to The end face 21 of the bladder bottom cover is welded to form the first-stage semi-finished product;

[0037] b. Take the first-stage semi-finished product and the shell body 3, and match the inner cup body mouth 12 with the shell body mouth 31, and use a laser welding machine or an argon arc welding machine to match the inner cup body mouth 12 and the shell body mouth Part 31 is welded to form the second stage semi-finished product;

[0038] c. Take the second-stage semi-finished product and the shell bottom cover 4, put the second-stage semi-finished product and the shell bottom cover 4 into a vacuum container, and mat...

Embodiment 2

[0048] Such as Figure 1 to Figure 6 As shown, a manufacturing process of a vacuum insulation cup includes the following steps:

[0049] a. Take the liner cup body 1 and the liner bottom cover 2, and match the bottom surface 11 of the liner cup body with the end surface 21 of the liner bottom cover, and use a laser welding machine or an argon arc welding machine to The end face 21 of the bladder bottom cover is welded to form the first-stage semi-finished product;

[0050] b. Take the first-stage semi-finished product and the shell body 3, and match the inner cup body mouth 12 with the shell body mouth 31, and use a laser welding machine or an argon arc welding machine to match the inner cup body mouth 12 and the shell body mouth Part 31 is welded to form the second stage semi-finished product;

[0051] c. Take the second-stage semi-finished product and the shell bottom cover 4, put the second-stage semi-finished product and the shell bottom cover 4 into a vacuum container, and mat...

Embodiment 3

[0061] Such as Figure 1 to Figure 6 As shown, a manufacturing process of a vacuum insulation cup includes the following steps:

[0062] a. Take the liner cup body 1 and the liner bottom cover 2, and match the bottom surface 11 of the liner cup body with the end surface 21 of the liner bottom cover, and use a laser welding machine or an argon arc welding machine to The end face 21 of the bladder bottom cover is welded to form the first-stage semi-finished product;

[0063] b. Take the first-stage semi-finished product and the shell body 3, and match the inner cup body mouth 12 with the shell body mouth 31, and use a laser welding machine or an argon arc welding machine to match the inner cup body mouth 12 and the shell body mouth Part 31 is welded to form the second stage semi-finished product;

[0064] c. Take the second-stage semi-finished product and the shell bottom cover 4, put the second-stage semi-finished product and the shell bottom cover 4 into a vacuum container, and mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com