Metal phosphide, preparation method thereof and application in supercapacitor

A technology of metal phosphides and supercapacitors, applied in the direction of phosphides, phosphorus compounds, chemical instruments and methods, etc., can solve problems such as low electronic conductivity, and achieve good conductivity, good rate performance, and high surface active sites Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

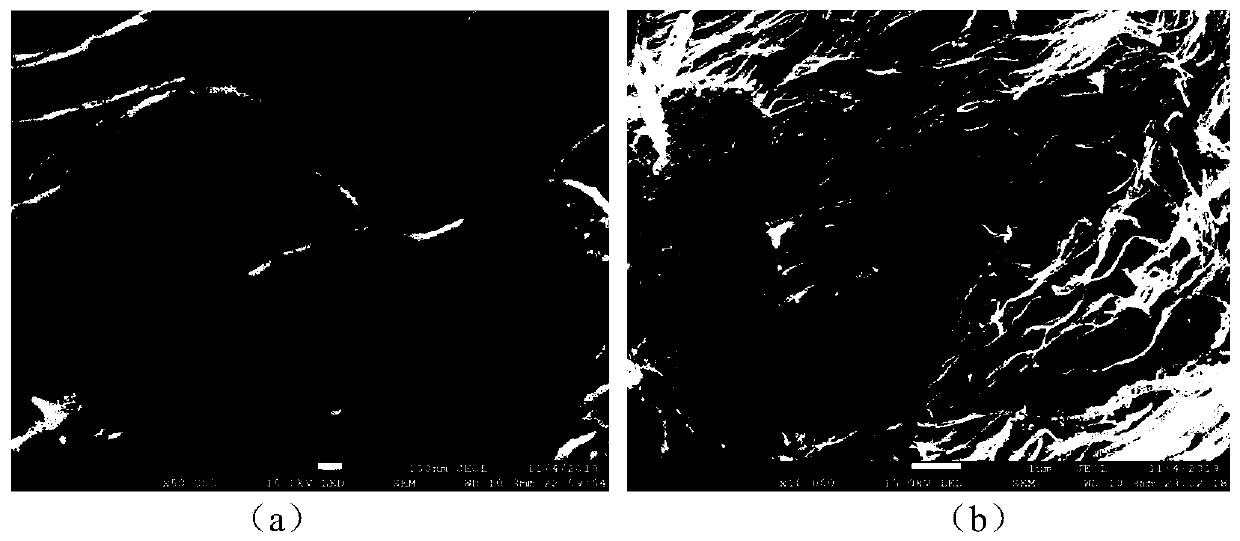

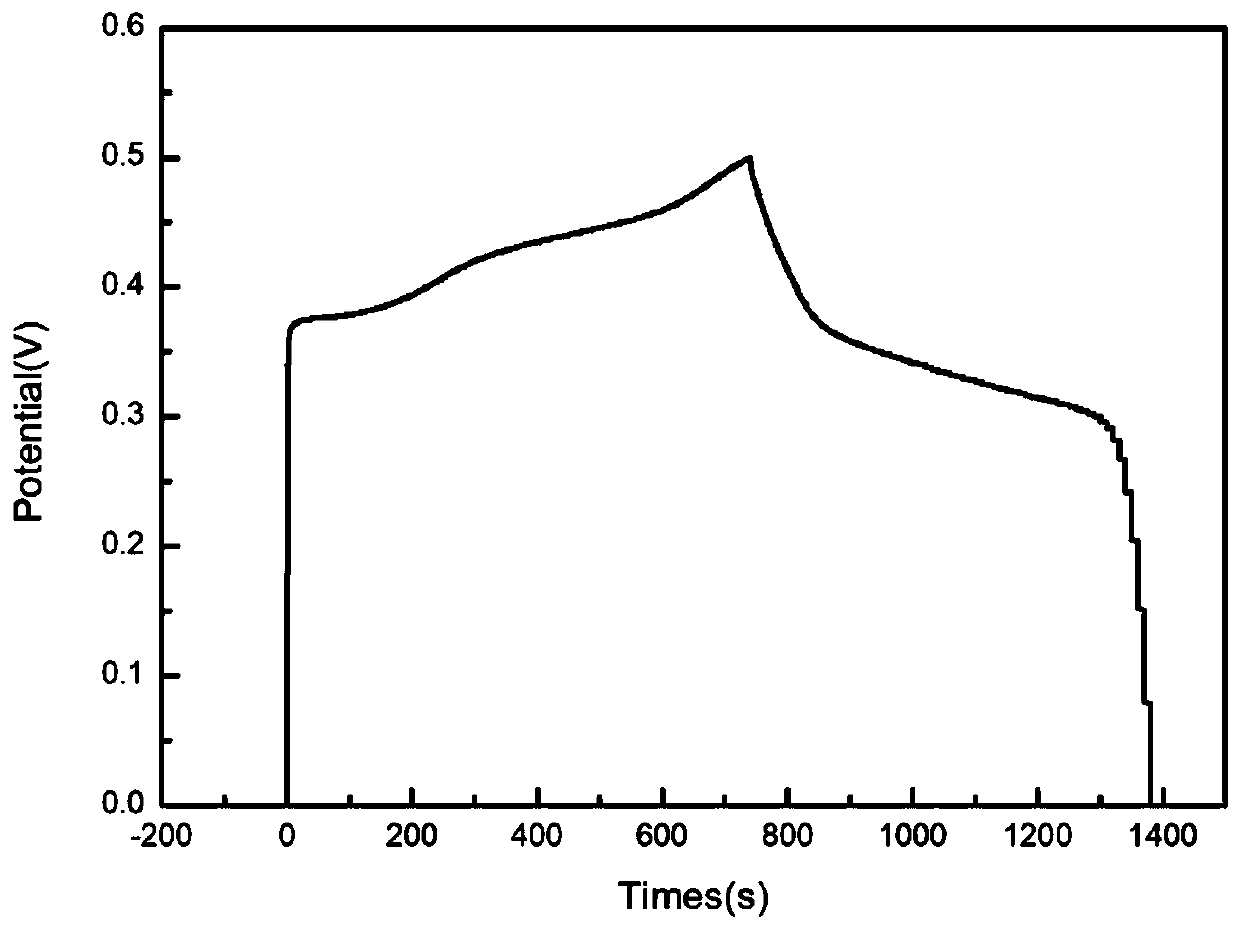

Image

Examples

Embodiment 1

[0043] The preparation method of a kind of metal phosphide of the present embodiment is to use elemental phosphorus, metal salt, cetyltrimethylammonium bromide as raw materials, first the raw materials are prepared into reaction precursors, secondly carry out hydrothermal reaction, pumping Filtration, drying and post-treatment processes, so that elemental phosphorus and metal salts fully react to form metal phosphides as electrode materials, and the method specifically includes the following steps:

[0044] (1) Reaction precursor preparation: at room temperature, cetyltrimethylammonium bromide and metal salt are added to deionized water according to a certain molar ratio, then heated in a water bath and stirred to make it completely dissolved, and the solution Pour into the PTFE liner, then add elemental phosphorus;

[0045]Wherein, the reaction precursor is prepared as follows:

[0046] (a) Pour 60 mL of deionized water into a beaker at room temperature;

[0047] (b) Weigh ...

Embodiment 2

[0058] The preparation method of a kind of metal phosphide of the present embodiment is to use elemental phosphorus, metal salt, cetyltrimethylammonium bromide as raw materials, first the raw materials are prepared into reaction precursors, secondly carry out hydrothermal reaction, pumping Filtration, drying and post-treatment processes, so that elemental phosphorus and metal salts fully react to form metal phosphides as electrode materials. Described method specifically comprises the following steps:

[0059] (1) Reaction precursor preparation: at room temperature, cetyltrimethylammonium bromide and metal salt are added to deionized water according to a certain molar ratio, then heated in a water bath and stirred to make it completely dissolved, and the solution Pour into the PTFE liner, then add elemental phosphorus;

[0060] Wherein, the reaction precursor is prepared as follows:

[0061] (a) Pour 60 mL of deionized water into a beaker at room temperature;

[0062] (b) W...

Embodiment 3

[0073] The preparation method of a kind of metal phosphide of the present embodiment is to use elemental phosphorus, metal salt, cetyltrimethylammonium bromide as raw materials, first the raw materials are prepared into reaction precursors, secondly carry out hydrothermal reaction, pumping Filtration, drying and post-treatment processes, so that elemental phosphorus and metal salts fully react to form metal phosphides as electrode materials.

[0074] (1) Reaction precursor preparation: at room temperature, cetyltrimethylammonium bromide and metal salt are added to deionized water according to a certain molar ratio, then heated in a water bath and stirred to make it completely dissolved, and the solution Pour into the PTFE liner, then add elemental phosphorus;

[0075] Wherein, the reaction precursor is prepared as follows:

[0076] (a) Pour 60 mL of deionized water into a beaker at room temperature;

[0077] (b) Weigh 0.3645g cetyltrimethylammonium bromide at room temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com