Preparation method of alpha-Fe2O3 nano laminated material and method for preparing benzaldehyde from material

A technology of nano-lamination and benzaldehyde, applied in the field of nano-materials, can solve the problems of difficult industrial application and unsatisfactory application effect, and achieve the effect of easy industrialization, good product performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

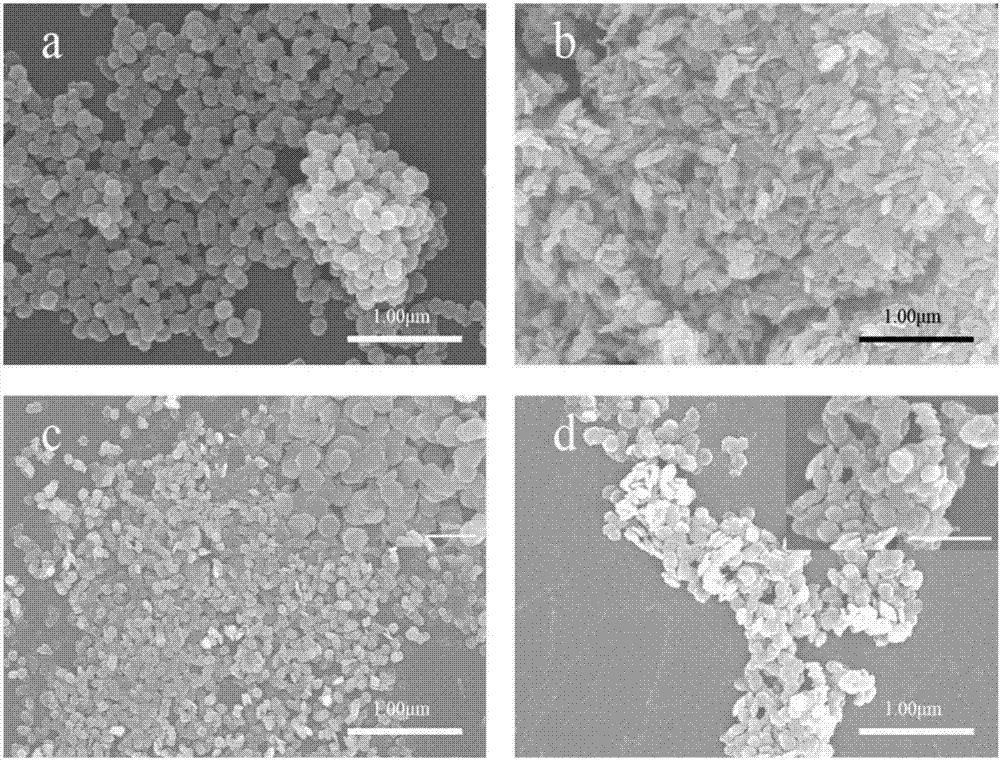

Image

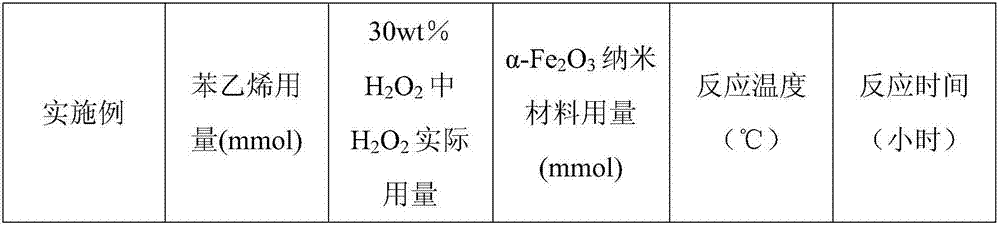

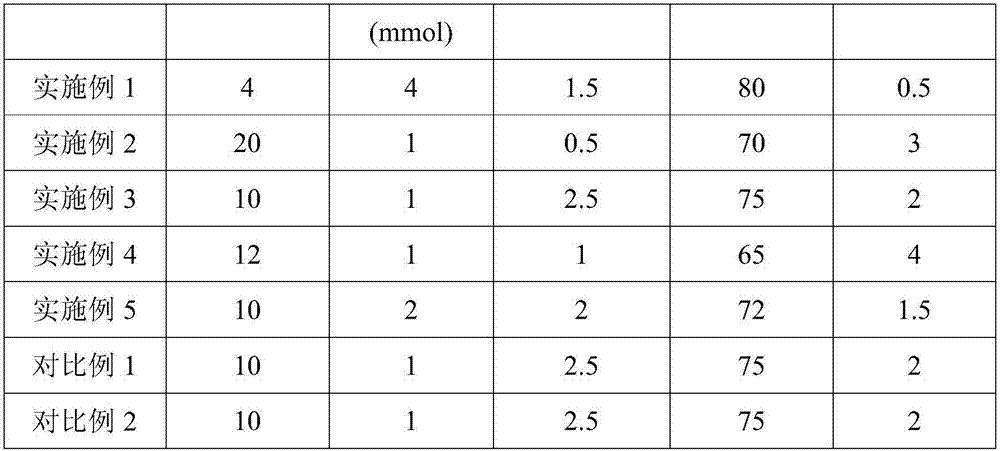

Examples

Embodiment 1

[0039] Pre-mixing step: sequentially add 2 g of FeCl to 250 g of ethanol3 ·6H 2 O, 1.5 grams of deionized water and 1.5 grams of sodium acetate, stirred at 150 rpm for 45 minutes, reacted for 2 hours in a constant temperature water bath at 60° C., stopped stirring, and obtained a mixed solution.

[0040] Concentration step: Concentrate the mixed solution obtained in the pre-mixing step at 90° C. for 12 hours to obtain a concentrated solution.

[0041] Hydrothermal synthesis step: take 100 grams of the concentrated solution obtained in the concentration step and add it to a polytetrafluoroethylene-lined reactor, add 6 grams of deionized water and 8 grams of sodium acetate, stir at 150 rpm for 45 minutes, seal the kettle, and then React at 180°C for 8 hours, cool to room temperature after the reaction, centrifuge and filter, collect the solid product, wash with absolute ethanol and distilled water, and obtain α-Fe after drying 2 o 3 Nanolaminated materials.

Embodiment 2

[0043] Pre-mixing step: sequentially add 3 grams of FeCl to 250 grams of ethanol 3 ·6H 2 O, 1.5 grams of deionized water and 2 grams of sodium acetate, stirred at 200 rpm for 60 minutes, reacted in a constant temperature water bath at 70° C. for 1 hour, stopped stirring, and obtained a mixed solution.

[0044] Concentration step: the mixed liquid obtained in the pre-mixing step was concentrated at 95° C. for 6 hours to obtain a concentrated liquid.

[0045] Hydrothermal synthesis step: take 100 grams of the concentrated solution obtained in the concentration step and add it to a polytetrafluoroethylene-lined reactor, add 8 grams of deionized water and 10 grams of sodium acetate, stir at a rate of 200 rpm for 60 minutes, seal the kettle, and then React at 160°C for 12 hours, cool to room temperature after the reaction, centrifuge and filter, collect the solid product, wash with absolute ethanol and distilled water, and obtain α-Fe after drying 2 o 3 Nanolaminated materials. ...

Embodiment 3

[0047] Pre-mixing step: sequentially add 1 g of FeCl to 250 g of ethanol 3 ·6H 2 O, 1.5 grams of deionized water and 1 gram of sodium acetate, stirred at 100 rpm for 30 minutes, reacted in a constant temperature water bath at 45°C for 3 hours, stopped stirring, and obtained a mixed solution.

[0048] Concentration step: the mixed liquid obtained in the pre-mixing step was concentrated at 75° C. for 72 hours to obtain a concentrated liquid.

[0049] Hydrothermal synthesis step: take 100 grams of the concentrated solution obtained in the concentration step and add it to a polytetrafluoroethylene-lined reactor, add 5 grams of deionized water and 6 grams of sodium acetate, stir at a rate of 100 rpm for 30 minutes, seal the kettle, and then React at 200°C for 6 hours, cool to room temperature after the reaction, centrifuge and filter, collect the solid product, wash with absolute ethanol and distilled water, and obtain α-Fe after drying 2 o 3 Nanolaminated materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com