Hydrogen peroxide modified graphite phase carbon nitride nanosheet and preparation method thereof

A graphitic carbon nitride and hydrogen peroxide technology, applied in the field of photocatalysis, can solve problems such as unfavorable large-scale promotion, low surface activity, unsatisfactory effect, etc., and achieve the effect of multiple surface active sites and surface performance optimization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

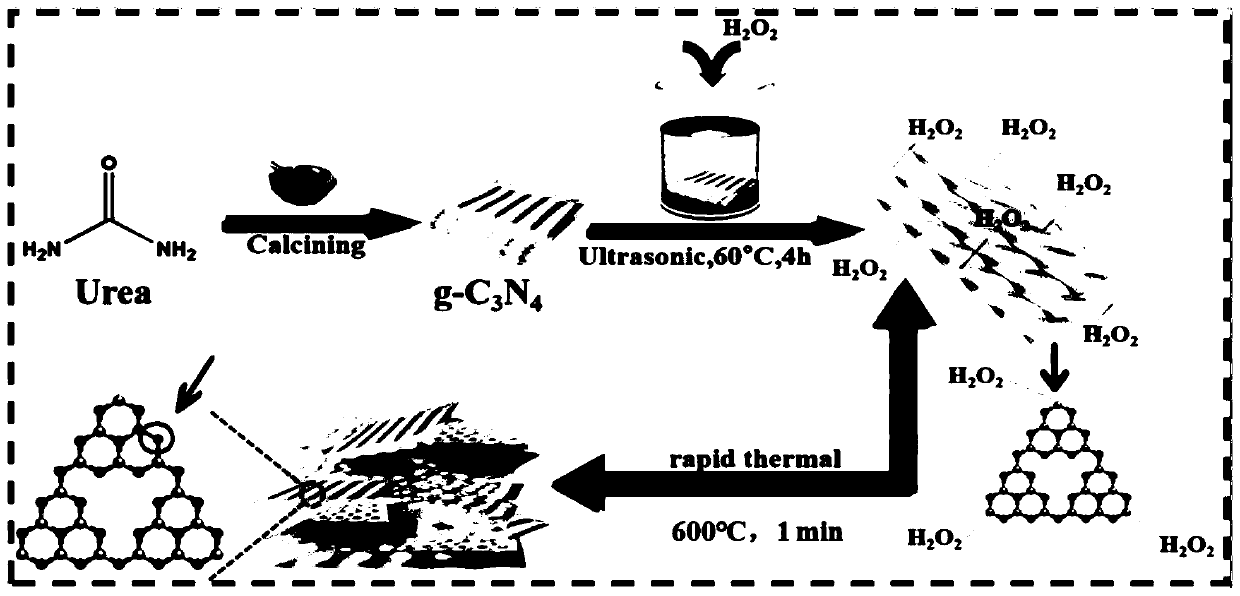

[0054] a H 2 o 2 g-C 3 N 4 The preparation method of nano sheet, comprises the following steps: specific as figure 1 Shown:

[0055] (1)Urea g-C 3 N 4 The preparation method:

[0056] Put 25g of urea in a covered ceramic crucible, control the heating rate of the muffle furnace to 8°C / min, heat the crucible to 550°C, and keep it for 3 hours; after cooling to room temperature, grind the solid matter in the crucible to obtain Pale yellow solid, namely Urea g-C 3 N 4 Powder (UCN).

[0057] (2)H 2 o 2 g-C 3 N 4 Preparation method of nanosheets:

[0058] 800mg Urea g-C 3 N 4 Powdered UCN added to H 2 o 2 (30%, 20mL) and absolute ethanol (10mL) in a mixed solvent, stirred at room temperature (25°C) for 30min and then ultrasonically (power 500W) for 12 hours to obtain a mixed solution; then pass the mixed solution obtained in the previous step through Centrifuge at 6000rpm for 10 minutes to obtain wet g-C 3 N 4 nanoflakes; then the wet g-C 3 N 4 The nanoflakes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com