Anaerobic flow biofilm reactor

A flow biological and membrane reactor technology, applied in anaerobic digestion treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of poor mixing effect of sewage and carrier, affecting microbial degradation, trouble, etc. The flow direction is stable, the decomposition is complete, and the effect of reducing stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

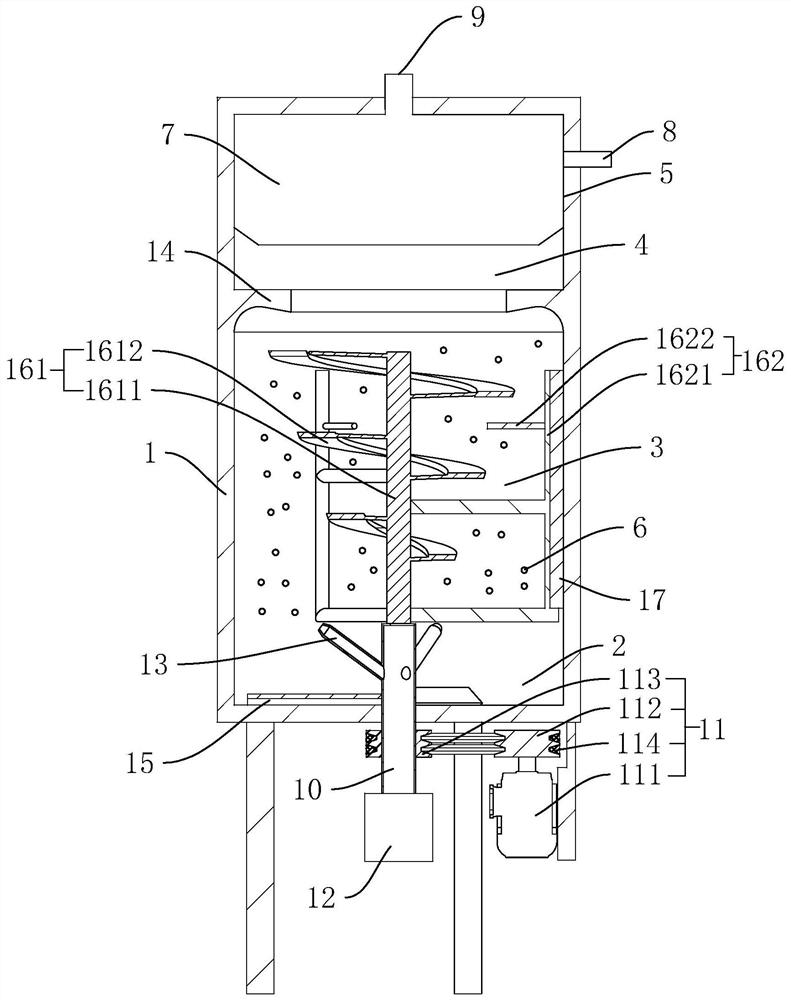

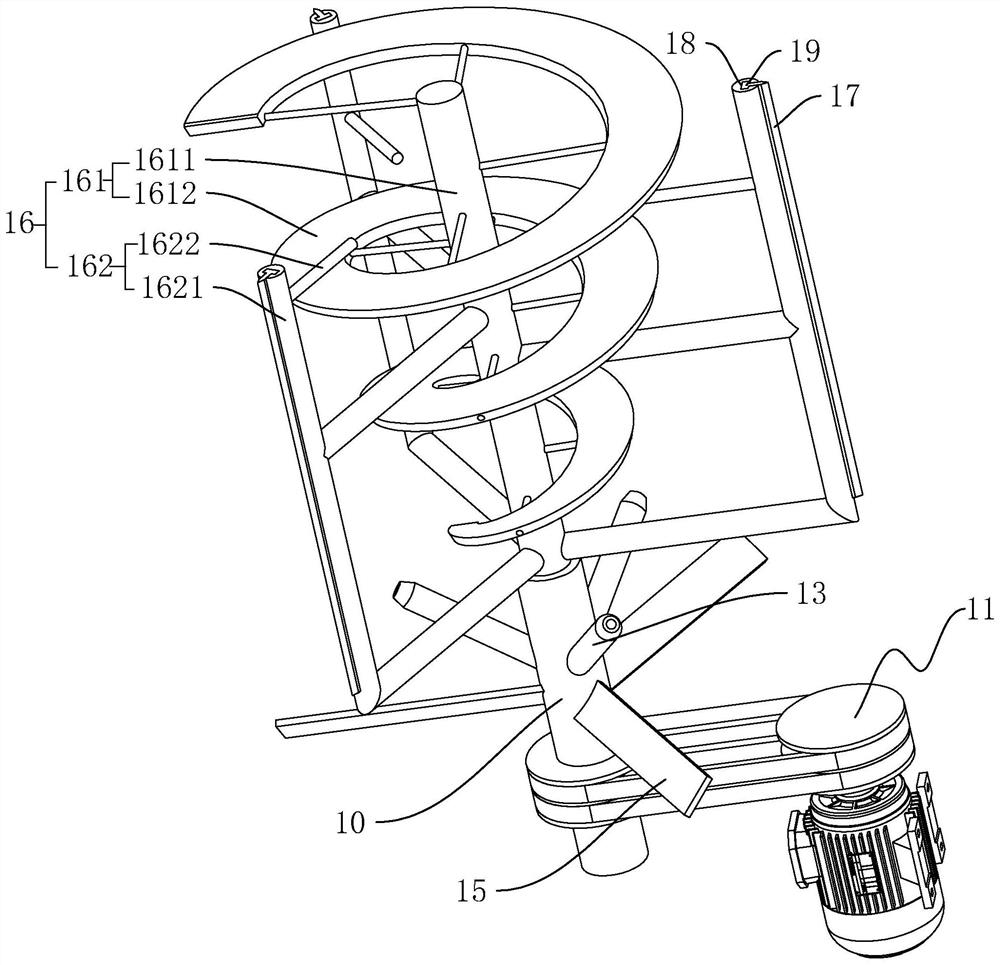

[0035] An anaerobic flow biofilm reactor, such as figure 1 As shown, a cylindrical reaction box 1 is included, and the axis of the reaction box 1 is vertically arranged. The reaction box 1 includes a water inlet area 2 , a reaction area 3 , a precipitation area 4 and a water outlet area 5 connected from bottom to top. The reaction zone 3 is provided with a small granular filler carrier 6, and the filler carrier 6 can usually be quartz sand, anthracite, activated carbon, ceramsite or zeolite and the like. A three-phase separator 7 is provided in the water outlet area 5, and the three-phase separator 7 is inserted into the precipitation area 4 to be set. Going out of the reaction box 1, the top of the three-phase separator 7 is provided with an exhaust pipe 9, and the exhaust pipe 9 is passed through the reaction box 1 and fixed on the top of the reaction box 1. This type is all existing settings, and will not be described here. Do repeat.

[0036]The bottom of the reaction b...

Embodiment 2

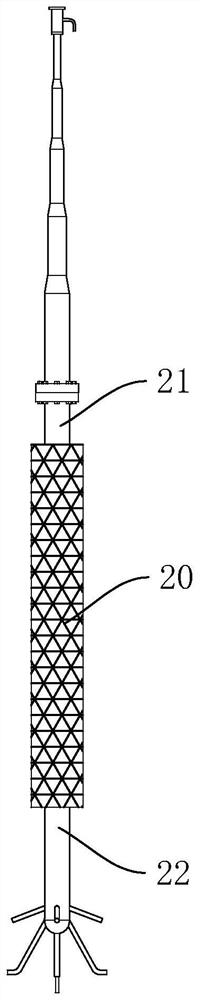

[0044] An anaerobic flow biofilm reactor, the difference between the second embodiment and the first embodiment is that it also includes a shell 20, the shell 20 is in the shape of a mesh cover, the upper end of the shell 20 is connected with a water inlet 21, and the shell 20 The lower end is provided with a water outlet 22. The reaction box 1 (not shown in the figure) is located in the casing 20, and the water inlet pipe 10 (not shown in the figure) is connected to the water inlet 21, and the water outlet 8 (not shown in the figure) is connected to the water outlet 22 set up.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com