Preparation method of microcrystalline glass for treating radioactive cesium contaminated soil

A technology of glass-ceramic and polluted soil, applied in the restoration of polluted soil and other directions, can solve the problems of affecting the compactness and stability of glass network structure, unsatisfactory curing effect, etc., achieving obvious curing effect, easy control of production process, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

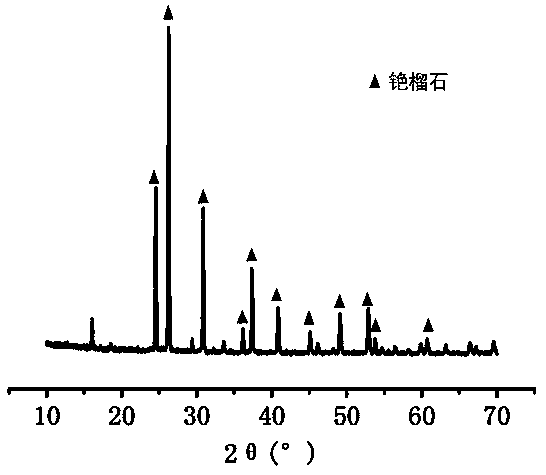

Examples

Embodiment 1

[0022] 1. Cesium hydroxide monohydrate (CsOH.H 2 O) 40.84g (simulated radionuclide) was dissolved in 43.60g silica sol with a mass concentration of 30%, and cesium silicate solution was obtained after mechanical stirring for 12 hours;

[0023] 2. Add 29.26g of metakaolin powder (simulated soil) to the cesium silicate solution, stir mechanically for 60 minutes, pour the slurry into the mold, put it in an oven and let it stand for 5 days at a temperature of 60°C to obtain a lump Solid, pulverizing and grinding the massive solid to obtain a cesium-containing precursor powder;

[0024] 3. The dried analytically pure SiO 2 55g, Al 2 o 3 4GB 2 o 3 17g, Na 2 CO 3 19g, CaCO 3 After 5g is ground and mixed evenly, pour it into a crucible, put the crucible into a muffle furnace, melt at a temperature of 1400°C for 2 hours at a heating rate of 10°C / min, and then shape and cool to obtain borosilicate glass , grinding borosilicate glass into borosilicate glass powder;

[0025] 4...

Embodiment 2

[0027] 1. Cesium hydroxide monohydrate (CsOH.H 2 O) 61.26g (simulated radionuclide) was dissolved in 65.40g silica sol with a mass concentration of 30%, and a cesium silicate solution was obtained after mechanical stirring for 24 hours;

[0028] 2. Add 43.89g of metakaolin powder (simulated soil) to the cesium silicate solution, stir mechanically for 90 minutes, pour the slurry into the mold, put it in an oven and let it stand for 7 days at a temperature of 70°C to obtain a lump Solid, pulverizing and grinding the massive solid to obtain a cesium-containing precursor powder;

[0029] 3. The dried analytically pure SiO 2 58g, Al 2 o 3 4GB 2 o 3 15g, Na 2 CO 3 16g, CaCO 3 After 7g is ground and mixed evenly, pour it into a crucible, put the crucible into a muffle furnace, melt at a temperature of 1500 °C for 2 hours at a heating rate of 10 °C / min, and then form and cool to obtain borosilicate glass , grinding borosilicate glass into borosilicate glass powder;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com