A kind of high expansion ratio liquid expansion agent and preparation method thereof

A liquid expansion, high expansion rate technology, applied in the field of building materials, can solve the problems of poor comprehensive performance, unfavorable production and popularization, and achieve the effects of improving strength, good migration and dispersion effect, and slowing expansion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

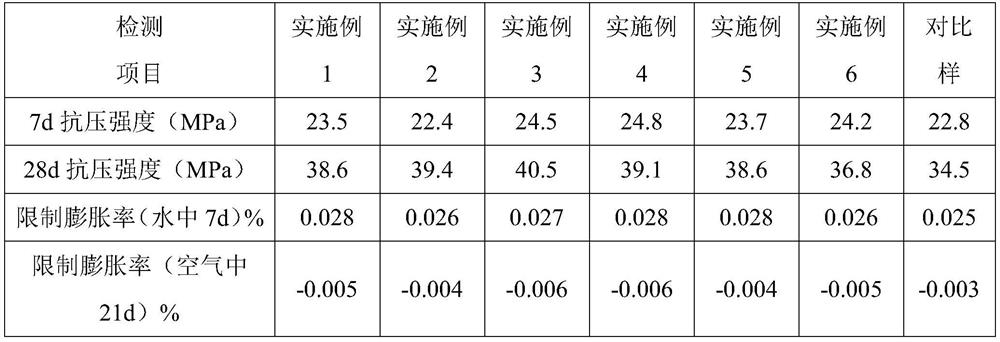

Examples

Embodiment 1

[0038] A method for preparing a liquid expansion agent with a high expansion rate, the total mass of raw materials is 100 parts, the solid content is about 10%, and it is mainly prepared from the following components:

[0039] Anhydrous aluminum sulfate: 0.4 parts

[0040] Modified calcium sulfoaluminate: 0.5 parts

[0041] Gypsum: 0.6 parts

[0042] Butanol: 0.1 parts

[0043] Simethicone oil: 0.2 parts

[0044] Span 80: 0.4 servings

[0045] Polypropylene alcohol 400: 0.8 parts

[0046] Lauryl polyoxyethylene ether: 3.8 parts

[0047] Propylene glycol methyl ether: 1.9 parts

[0048] Polyacrylamide: 1.2 parts

[0049] Step 1: Weigh 0.4 parts of anhydrous aluminum sulfate and 0.5 parts of modified sulfoaluminic acid

[0050] Calcium, 0.6 parts of gypsum, 0.1 parts of butanol, 0.2 parts of simethicone, 0.4 parts of Span 80 and 90 parts of water were placed in the reaction kettle, the temperature of the water bath was controlled at 40°C, and the temperature was stirred fo...

Embodiment 2

[0054] A method for preparing a liquid expansion agent with a high expansion rate, the total mass of raw materials is 100 parts, the solid content is about 10%, and it is mainly prepared from the following components:

[0055] Anhydrous aluminum sulfate: 0.4 parts

[0056] Modified calcium sulfoaluminate: 0.5 parts

[0057] Gypsum: 0.7 parts

[0058] Butanol: 0.1 parts

[0059] Simethicone oil: 0.1 parts

[0060] Span 80: 0.2 servings

[0061] Polypropylene alcohol 400: 0.5 part

[0062] Lauryl polyoxyethylene ether: 4.6 parts

[0063] Propylene glycol methyl ether: 2.3 parts

[0064] Polyacrylamide: 0.8 parts

[0065] Step 1: Weigh 0.4 parts of anhydrous aluminum sulfate, 0.5 parts of modified calcium sulfoaluminate, 0.7 parts of gypsum, 0.1 parts of butanol, 0.1 parts of simethicone, 0.2 parts of Span 80 and 90 parts of water in the reaction kettle , control the temperature of the water bath at 40°C, and stir at constant temperature for 0.5h.

[0066] Step 2: Raise ...

Embodiment 3

[0069] A method for preparing a liquid expansion agent with a high expansion rate, the total mass of raw materials is 100 parts, the solid content is about 10%, and it is mainly prepared from the following components:

[0070] Anhydrous aluminum sulfate: 0.5 part

[0071] Modified calcium sulfoaluminate: 0.6 parts

[0072] Gypsum: 0.7 parts

[0073] Butanol: 0.2 parts

[0074] Simethicone oil: 0.15 parts

[0075] Span 80: 0.3 servings

[0076] Polypropylene alcohol 400: 0.9 parts

[0077] Lauryl polyoxyethylene ether: 4.0 parts

[0078] Propylene glycol methyl ether: 2.0 parts

[0079] Polyacrylamide: 0.6 parts

[0080] Step 1: Weigh 0.5 parts of anhydrous aluminum sulfate, 0.6 parts of modified calcium sulfoaluminate, 0.7 parts of gypsum, 0.2 parts of butanol, 0.15 parts of simethicone, 0.3 parts of Span 80 and 90 parts of water in the reaction kettle , control the temperature of the water bath at 45 ° C, and stir at constant temperature for 1 h.

[0081] Step 2: Rai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com