High-strength prestressed duct grouting agent

A channel grouting and prestressing technology, applied in the field of grouting agents, can solve problems such as lack of control, and achieve the effect of improving mechanical strength properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

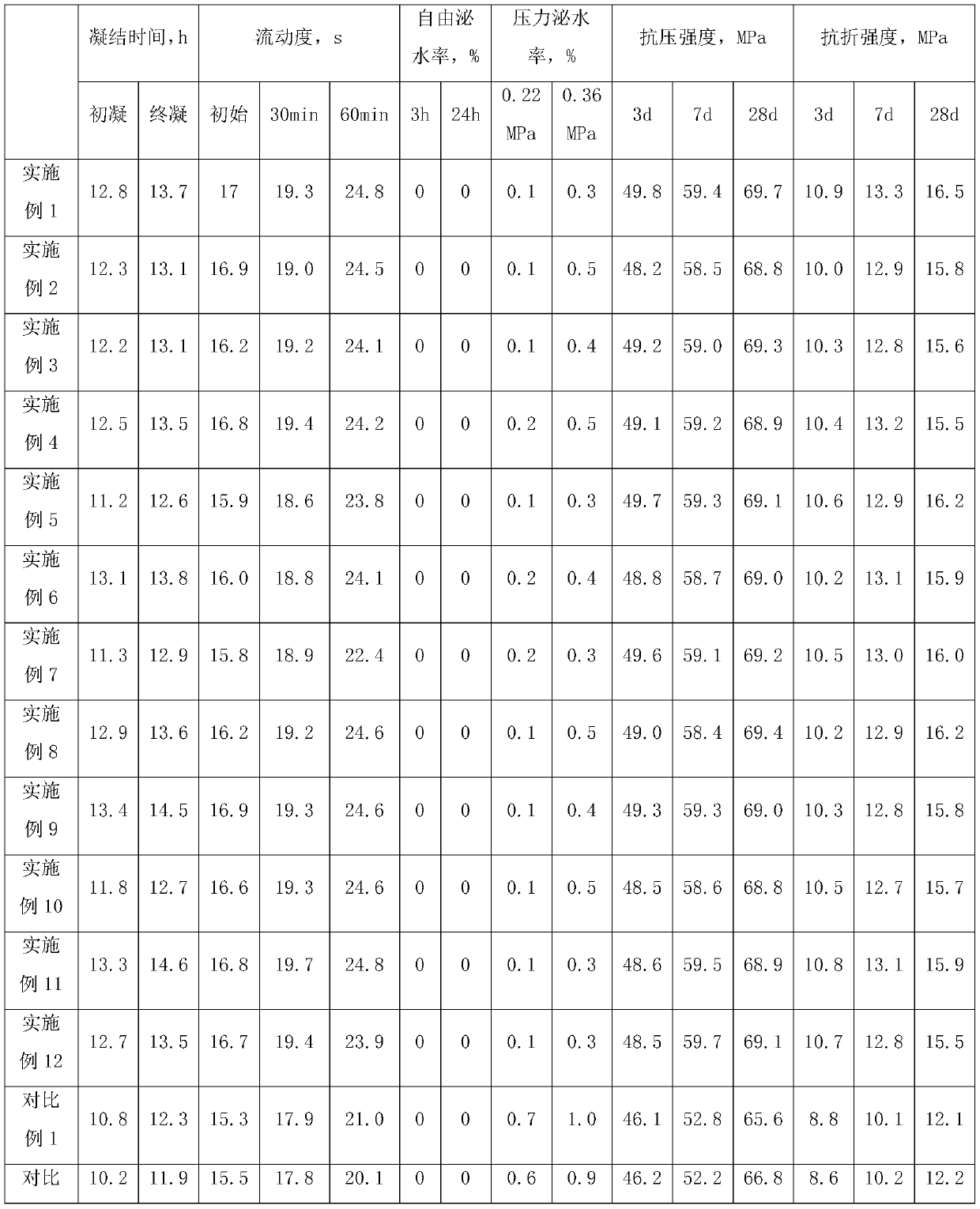

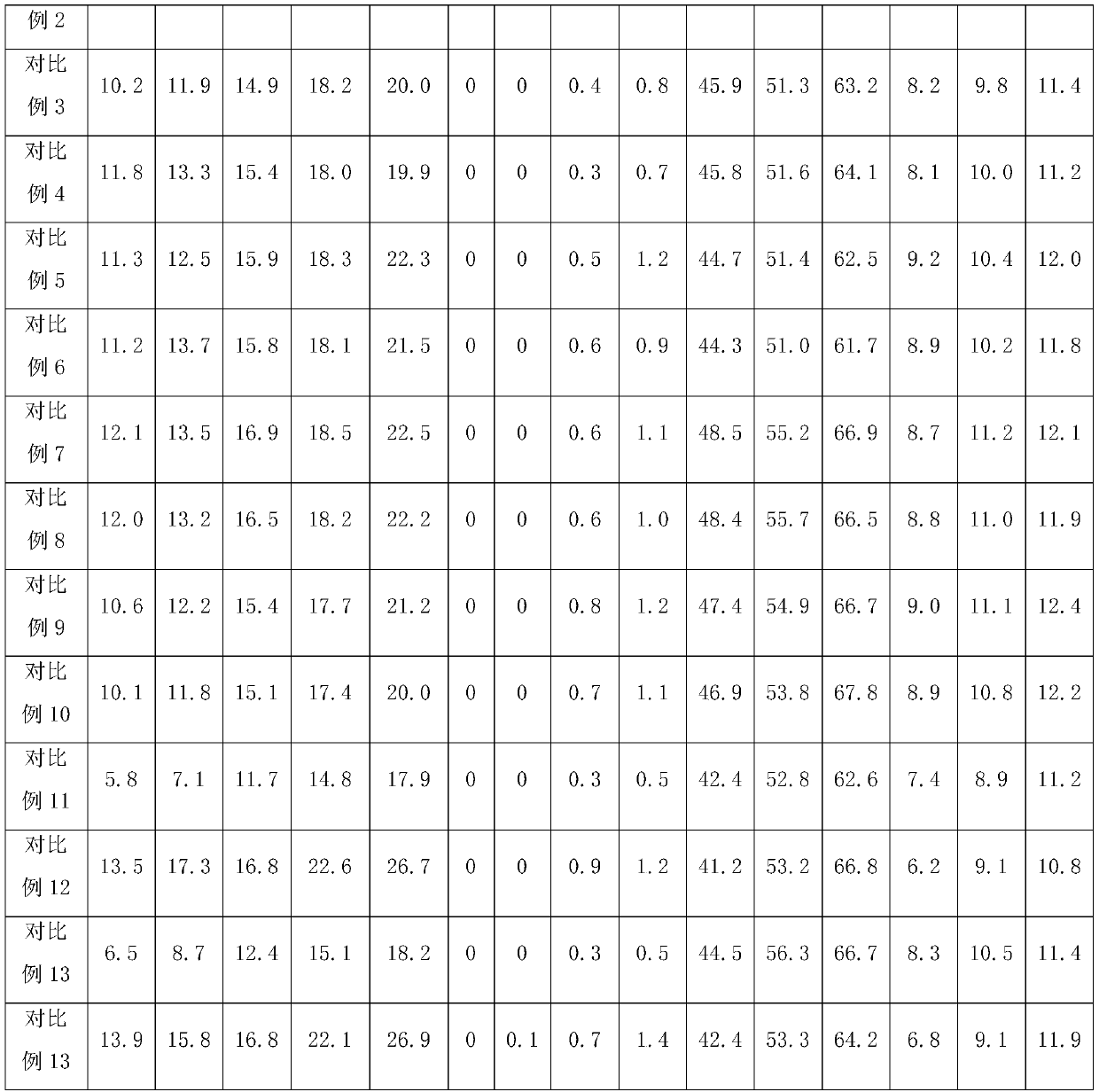

Examples

Embodiment 1

[0029] The high-strength prestressed channel grouting agent provided in this example includes 39wt% of viscosity modifier, 28wt% of coagulation regulator, 22wt% of modified sodium hydroxide powder, 10.5wt% of water reducer, and 0.5wt% of defoamer ;

[0030] Wherein, the concrete preparation method of viscosity modifier is:

[0031] A1. Take superfine calcium carbonate hollow balls and pullulan polysaccharide according to the weight ratio of 1:2, add water 20 times the weight of pullulan polysaccharide and / or welan gum, and stir for 30min under a pressure of 0.2MPa. 800r / min, to obtain a suspension;

[0032] A2. Take the filter residue by membrane filtration, and vacuum-dry to obtain the finished product of the viscosity modifier. The absorbance of the pullulan in the ultrafine calcium carbonate hollow spheres is detected by a spectrophotometer, and compared with the absorbance of the original pullulan, the encapsulation efficiency of the pulland is measured to be 92.93%.

...

Embodiment 2

[0038] The high-strength prestressed channel grouting agent provided in this embodiment includes 42wt% of viscosity modifier, 30wt% of coagulation regulator, 15wt% of modified sodium hydroxide powder, 12.5wt% of water reducer, and 0.5wt% of defoamer The concrete preparation method of viscosity modifier, coagulation regulator is identical with embodiment 1.

Embodiment 3

[0040] The high-strength prestressed channel grouting agent provided in this example includes 34wt% of viscosity modifier, 27wt% of coagulation regulator, 24wt% of modified sodium hydroxide powder, 14.5wt% of water reducer, and 0.5wt% of defoamer The concrete preparation method of viscosity modifier, coagulation regulator is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com