Novel modified epoxy resin adhesive for construction and preparation method thereof

A technology for epoxy resin and construction, applied in the direction of epoxy resin glue, adhesive, polymer adhesive additive, etc., it can solve the problems of complicated construction, unsatisfactory compressive strength, slow curing rate, etc. The effect of sagging distance, shortening gel time and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

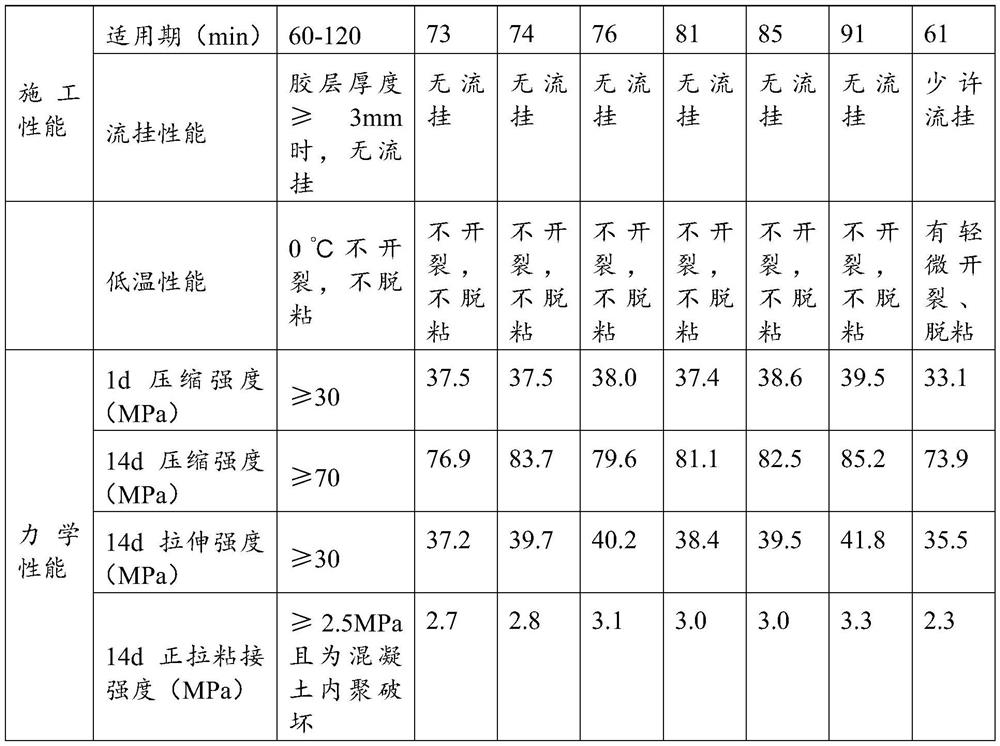

Examples

Embodiment 1

[0031] Adhesive 1 was obtained according to the following preparation method:

[0032] 1) Carboxyl-terminated nitrile rubber (CTBN) is preheated at 60-70°C for 0.5-1.0 hours before use, and then weigh 5 parts of preheated carboxyl-terminated nitrile rubber (CTBN) and 100 parts of epoxy resin (EP ), add it into the reactor with a stirrer and a thermometer, control the speed of the stirrer at 400-600r / min, stir the reactant evenly, add the accelerator 2,4,6-tri-( Dimethylaminomethyl) phenol (DMP-30) 3.2 parts, stop heating after reacting for 2.0 to 6.0 hours to obtain a modified CTBN / EP matrix.

[0033] 2) Dry mix 100 parts of cement and 170 parts of filler A in advance according to the proportion, and then add it to the reactor of the modified CTBN / EP matrix in step 1), and then add 15 parts of curing agent and 45 parts of water repellent , 10 parts of diluent, 2 parts of coupling agent and 1.6 parts of defoamer were fully stirred and mixed to obtain adhesive 1.

[0034] The ...

Embodiment 2

[0036] Adhesive 2 was obtained according to the following preparation method:

[0037] 1) Preheat carboxy-terminated nitrile rubber (CTBN) at 60-70°C for 0.5-1.0 hours before use, then weigh 30 parts of preheated carboxyl-terminated nitrile rubber (CTBN) and 100 parts of epoxy resin (EP ), add it into the reactor with a stirrer and a thermometer, control the speed of the stirrer at 400-600r / min, stir the reactant evenly, add the accelerator 2,4,6-tri-( Dimethylaminomethyl) phenol (DMP-30) 0.8 parts, stop heating after reacting for 2.0 to 6.0 hours to obtain a modified CTBN / EP matrix.

[0038] 2) Dry mix 170 parts of cement and 85 parts of filler A in advance according to the proportion, and then add it to the reactor of the modified CTBN / EP matrix in step 1), and then add 45 parts of curing agent and 30 parts of water repellent , 15 parts of diluent, 0.5 part of coupling agent and 0.2 part of defoamer were fully stirred and mixed to obtain adhesive 2.

[0039] The composition ...

Embodiment 3

[0041] Adhesive 3 was obtained according to the following preparation method:

[0042] 1) Preheat carboxy-terminated nitrile rubber (CTBN) at 60-70°C for 0.5-1.0 hours before use, then weigh 20 parts of preheated carboxyl-terminated nitrile rubber (CTBN) and 100 parts of epoxy resin (EP ), add it into the reactor with a stirrer and a thermometer, control the speed of the stirrer at 400-600r / min, stir the reactant evenly, add the accelerator 2,4,6-tri-( Dimethylaminomethyl) phenol (DMP-30) 2.5 parts, stop heating after reacting for 2.0-6.0 hours, and obtain a modified CTBN / EP matrix.

[0043] 2) Dry mix 100 parts of cement and 155 parts of filler A in advance according to the proportion, and then add it to the reactor of the modified CTBN / EP matrix in step 1), and then add 20 parts of curing agent and 40 parts of water repellent , 11 parts of diluent, 1 part of coupling agent and 1 part of defoamer were fully stirred and mixed to obtain adhesive 3.

[0044] The composition of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com