Multi-component high-activity carbon source Carbon-5 as well as preparation and application thereof

A composite, highly active technology, applied in the fields of special compound water treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of slow domestication, slow effect, high price, etc., and achieve fast domestication. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

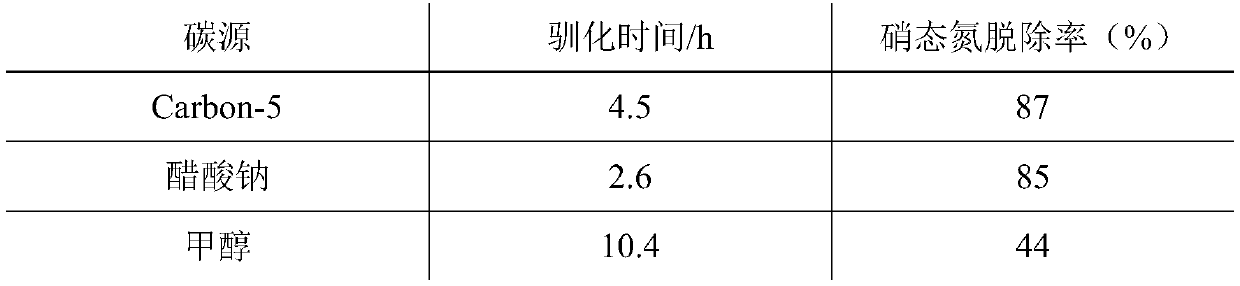

Embodiment 1

[0026] Take 500KG of mildly rotten apple and pear mixture (the rotten area is less than 10%), remove the mildewed part and use a beater to beat it into a slurry with a particle size of 3 mm to obtain a slurry of about 450KG, then take the mixed cornstarch production wastewater and glycerin production wastewater The mixed solution (density 1.18g / cm 3 , COD 272,000 mg / L, lime water adjusted to pH 6.3) about 110KG, fully mixed and poured into 1m 3 Seal the fermentation tank and inoculate 0.28KG of activated yeast, ferment with alcohol at 25°C for 7 days, filter through a 100-mesh sieve to get the supernatant to obtain 236KG of supernatant, pour it into a 500KG fermentation tank, inoculate 0.236KG of activated acetic acid bacteria, and ferment, and the fermentation is completed. Then adjust the pH to 7.0 with lime water and pass through a 200-mesh sieve to obtain Carbon-5, a clear liquid carbon source. The carbon source related parameters obtained from the test are COD 820,000 mg...

Embodiment 2

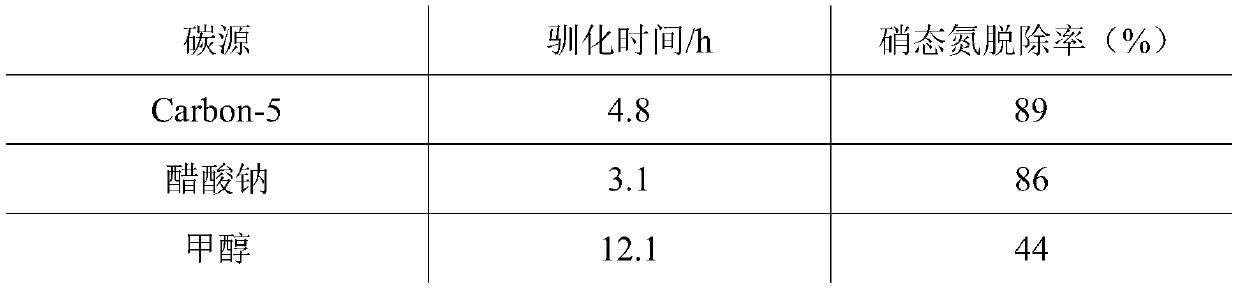

[0031] Take 500KG of mildly rotten corn and zucchini mixture (rotten area is less than 10%), remove the mildewed part and use a beater to beat it into a slurry with a particle size of 3 mm to obtain about 420KG of slurry, then take the mixed cornstarch production wastewater and glycerin wastewater ( Density 1.18g / cm 3 ,COD 272,000 mg / L, pH 6.3, lime water to adjust pH) about 105KG, fully mix and pour into 1m 3 Seal the fermenter and inoculate 0.27KG of activated yeast, ferment at 25°C for 7 days, filter through a 100-mesh sieve to get the supernatant to obtain 213KG of the supernatant and pour it into the 500KG fermenter to inoculate 0.213KG of acetic acid bacteria to activate and ferment, after the fermentation is completed, use The lime water was adjusted to pH 7.0 and passed through a 200-mesh sieve to obtain Carbon-5, a clear liquid carbon source. Test carbon source related parameters COD 780,000 mg / L, density 1.3g / cm 3 , after the viscosity is 5.32cp, it is stored in se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com