A kind of colloidal photonic crystal film that does not change color after bending and preparation method of patterned colloidal photonic crystal film

A technology of colloidal photonic crystals and thin films, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve problems such as cracks and flexibility, and achieve high flexibility, stability, deformation avoidance, and excellent durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

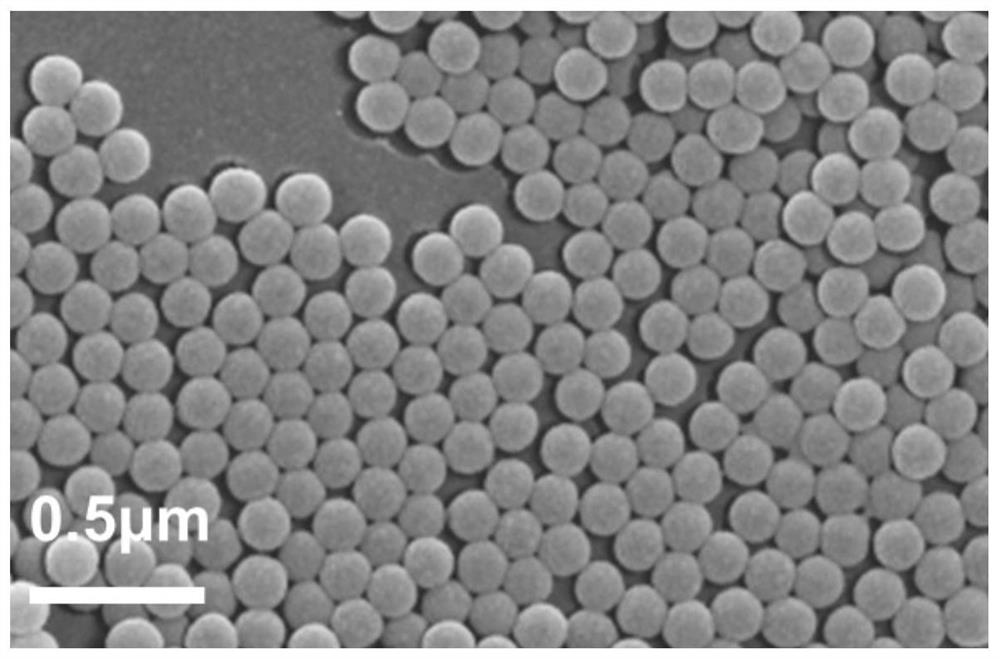

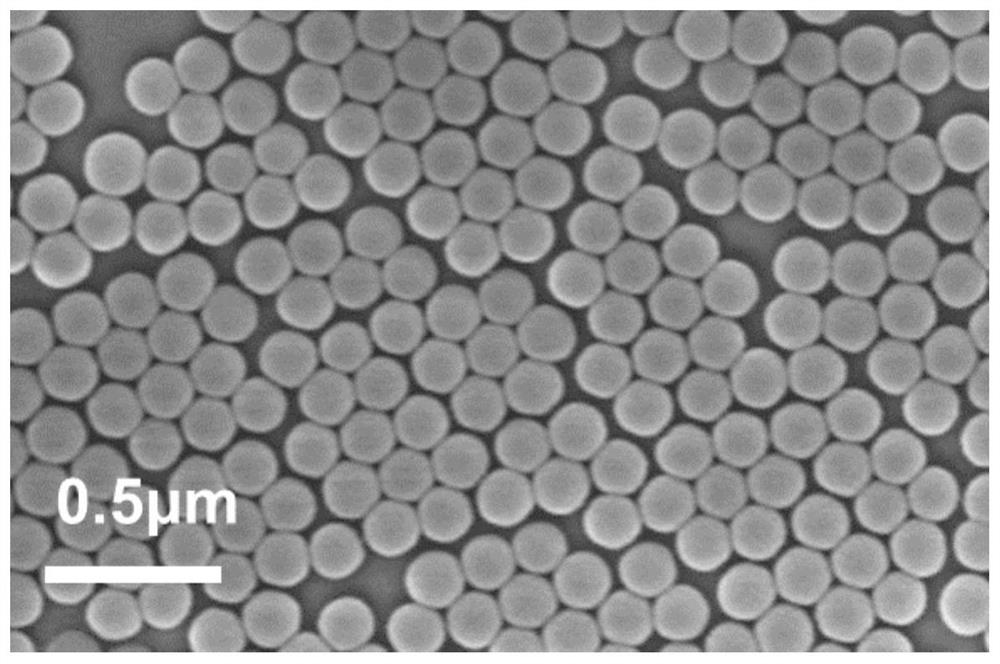

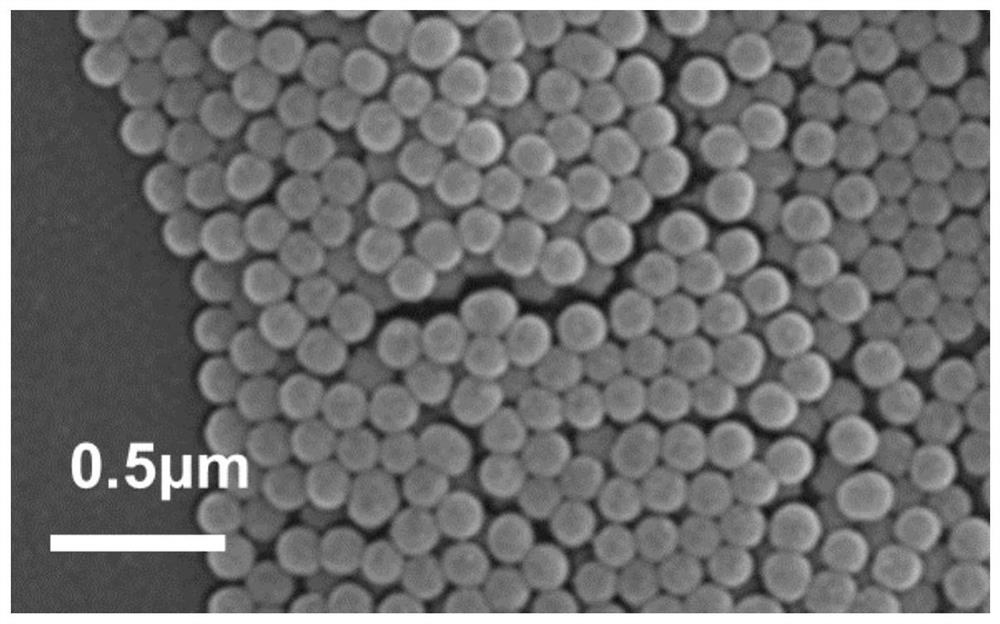

Image

Examples

specific Embodiment approach 1

[0047] DETAILED DESCRIPTION OF THE INVENTION He is a method for preparing a colored colored colloidal photonic crystal film to be completed as follows:

[0048] First, prepare silica nanoparticles:

[0049] 1, the solution A or solution B is magnetically stirred to obtain a silica suspension;

[0050] The solution A described in step 1 1 is a mixture of orthosilicate, anhydrous ethanol, 25% to 28% of the pressure-resistant distillation; mixture of 25% to 28% of the mixture of 25% to 28%;

[0051] The solution B described in step 1 1 is a mixture of ammonia water of the decompression distillation of orthosate, anhydrous ethanol and mass fraction of 25% to 28%;

[0052] 2, the silica suspension is centrifuged, remove the supernatant to obtain a precipitated substance; use anhydrous ethanol to clean the precipitated substance to 6 times to 5 times to obtain a precipitated substance after cleaning;

[0053] 3, the cleaned precipitated substance is naturally dried or placed in a blower...

specific Embodiment approach 2

[0069] DETAILED DESCRIPTION OF THE INVENTION Different: The present embodiment differs from the specific embodiment: the decompression distillation of orthosilicate, anhydrous ethanol, and mass fraction of 25% to 28% in the solution A in the step one. The volume ratio of ammonia water and deionized water is 1:20: (1 ~ 2): (1 ~ 2). Other steps are the same as specific embodiments.

specific Embodiment approach 3

[0070] BEST MODE FOR CARRYING OUT THE INVENTION 3: The present embodiment and the specific embodiment one or two of the specific embodiment are: 25% of the decompression distillation of the decompression of the decompression in the solution B described in the step one. The volume ratio of ~ 28% ammonia is 1:20: (1 ~ 5). Other steps are identical to those of the specific embodiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com