Preparation method of long-acting metal lithium reference electrode for lithium battery

A reference electrode and metal lithium technology, which is applied in the field of preparation of long-acting metal lithium reference electrodes, can solve the problems that the reference electrode cannot provide a stable reference potential, its own potential fluctuation, high reactivity, etc., and achieves inhibition of corrosion phenomenon, The effect of prolonging the service life and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

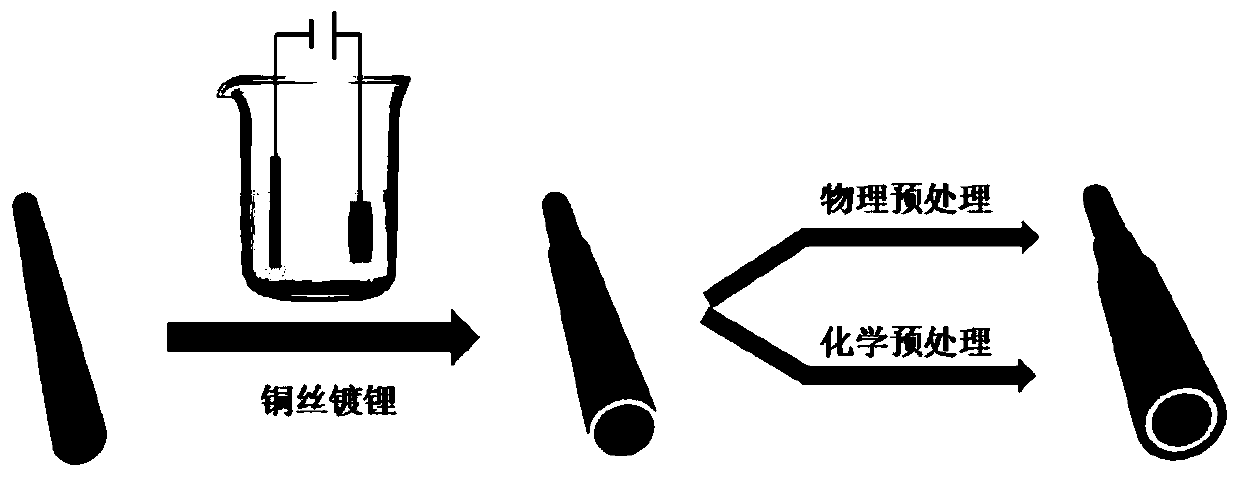

[0025] Example 1: Soak the original copper wire in a 1.0mol / L lithium hexafluorophosphate aqueous solution, take out the copper wire after 2 hours and dry it; place the dried copper wire in a solvent containing 1,3-dioxolane and dimethyl ether , in the electrolytic cell of lithium lithium salt of bistrifluoromethanesulfonimide, the current density of the control electroplating is 0.1mA cm -2 , Li deposition capacity is 0.1mAh cm -2 . After lithium plating is finished, clean the surface of lithium-plated copper wire with dimethyl ether pure solvent, soak it in fluoroethylene carbonate solvent for 5 hours after it is completely dry, then take it out and wait for the solvent to dry naturally to get the reference electrode .

Embodiment 2

[0026] Embodiment 2: Soak the original copper wire in the lithium perchlorate aqueous solution of 0.01mol / L, after 10h, the copper wire is taken out and dried; the dried copper wire is placed in fluoroethylene carbonate and diethyl carbonate As a solvent, lithium hexafluorophosphate is electroplated in an electrolyte system of lithium salt, and the current density is controlled at 5mA cm -2 , Li deposition capacity is 5mAh cm -2 . After lithium plating is finished, clean the surface of lithium-plated copper wire with diethyl carbonate pure solvent, and place it in N after it is completely dry. 2 Under the atmosphere, heat up and stand for 12h. Then the reference electrode can be obtained by taking out the lithium-coated copper wire.

Embodiment 3

[0027] Example 3: Soak the original copper wire in a 0.1mol / L lithium hexafluoroarsenate aqueous solution, take out the copper wire after 5 hours and dry it; place the dried copper wire in a mixture of 1,3-dioxolane and Dimethyl ether is used as a solvent, lithium bistrifluoromethanesulfonylimide is a lithium salt, and lithium nitrate is used as an additive for lithium plating in the electrolyte, and the lithium deposition current density is controlled to be 1.0mA cm -2 , with a capacity of 1.0mAh cm -2 . After lithium plating, clean the surface of lithium-plated copper wire with dimethyl ether pure solvent, soak it in the NMP solution of P4S16 for 1 hour after it is completely dry, and then take out the reference electrode after the solvent is naturally dried.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com