High-current repetition frequency strontium titanate-carbon nanotube dielectric cathode and preparation method thereof

A carbon nanotube and repetition frequency technology, which is used in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc. The problem of large enhancement coefficient, etc., achieves the effects of good emission uniformity and stability, improved flashover emission probability, and improved high-current emission life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

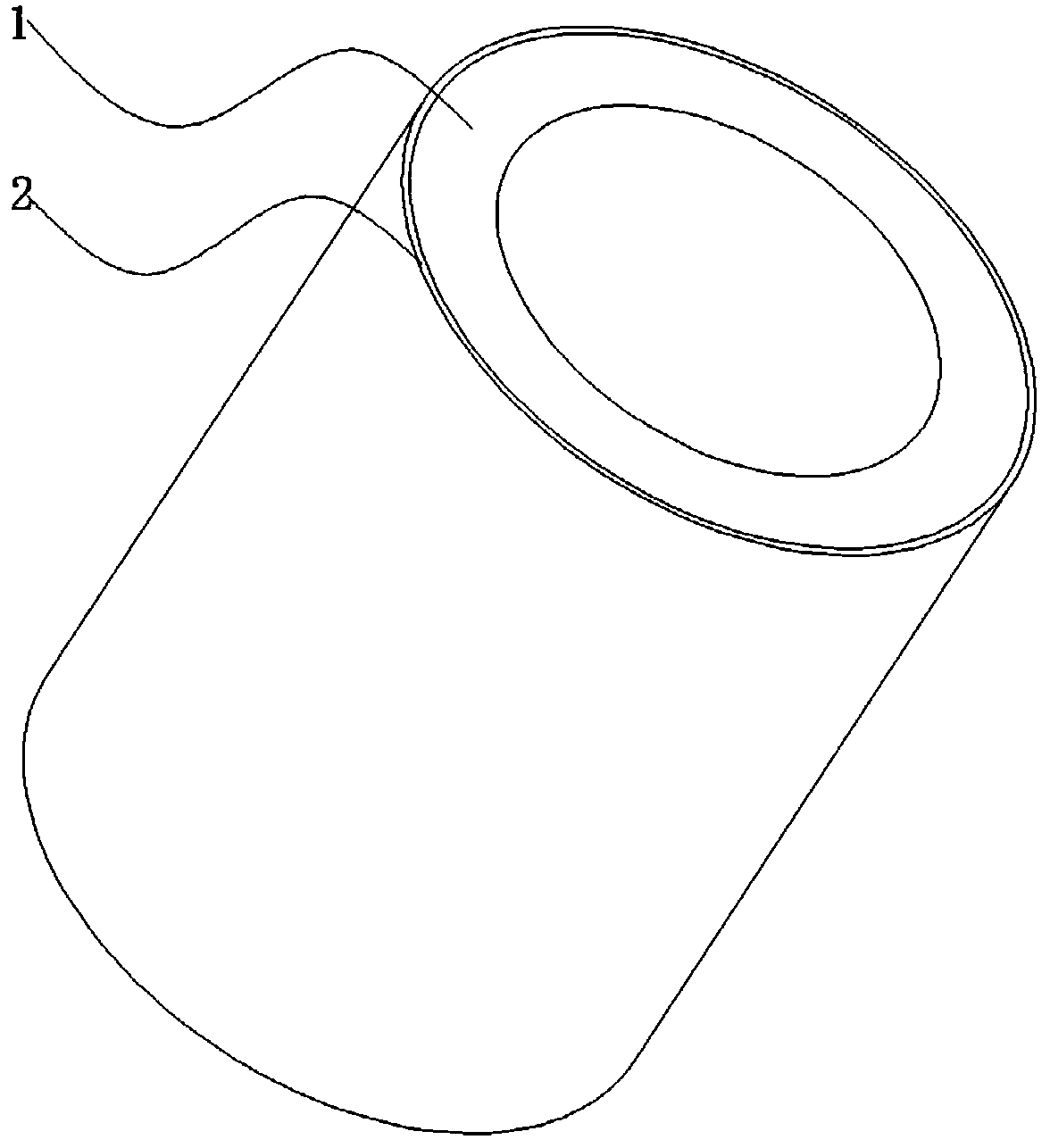

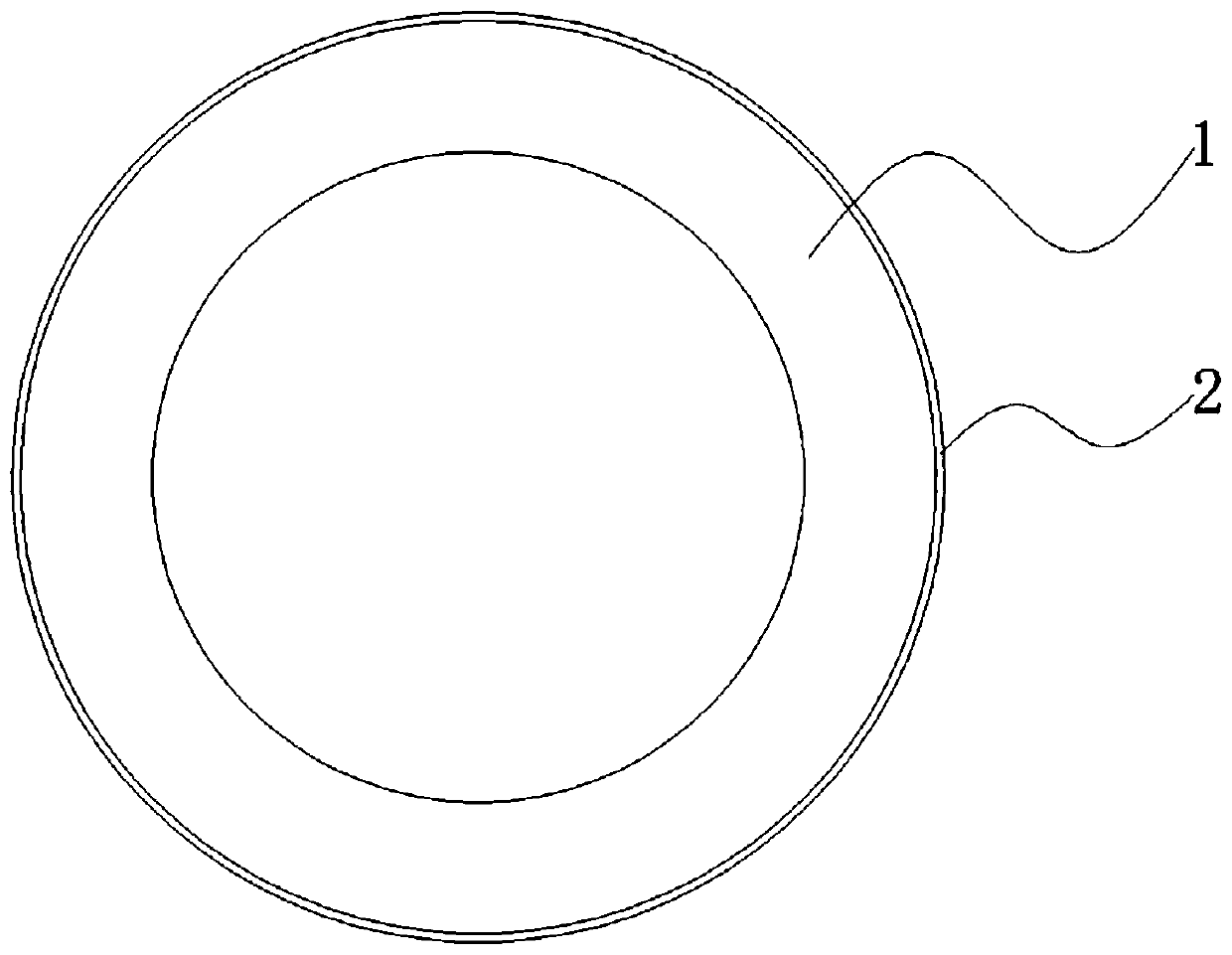

[0049] A high-current repetition frequency strontium titanate-carbon nanotube dielectric cathode in this embodiment includes a tubular cathode body made of SrTiO3 ceramics, the side of the cathode body is a rough surface, and the side of the cathode body is attached with an emission layer made of carbon nanotubes. The thickness of the emission layer is 0.1mm, and SiO2-B2O-ZnO glass powder is added, and the cathode body and the emission layer are co-sintered to form.

[0050] A method for preparing a high-current repetition frequency strontium titanate-carbon nanotube dielectric cathode in this embodiment includes the following steps:

[0051] Step a: use concentrated nitric acid to carry out carboxylation enhanced activity treatment to carbon nanotubes, and add 0.1% and cellulose; Mix carbon nanotubes and 5% terpineol, grind and make the first slurry; SiO2-B2O - ZnO glass powder and 5% terpineol are mixed and ground to obtain the second slurry; the first slurry and the second sl...

Embodiment 2

[0057] A high-current repetition frequency strontium titanate-carbon nanotube dielectric cathode in this embodiment includes a tubular cathode body made of SrTiO3 ceramics, the side of the cathode body is a rough surface, and the side of the cathode body is attached with an emission layer made of carbon nanotubes. The thickness of the emission layer is 1mm, and SiO2-B2O-ZnO glass powder is added, and the cathode body and the emission layer are co-sintered to form.

[0058] A method for preparing a high-current repetition frequency strontium titanate-carbon nanotube dielectric cathode in this embodiment includes the following steps:

[0059] Step a: use concentrated nitric acid to carry out carboxylation enhanced activity treatment to carbon nanotubes, and add 0.1% and cellulose; Mix carbon nanotubes and 1% terpineol, grind and make the first slurry; SiO2-B2O -ZnO glass powder and 1% terpineol were mixed and ground to obtain the second slurry; the first slurry and the second sl...

Embodiment 3

[0065] A high-current repetition frequency strontium titanate-carbon nanotube dielectric cathode in this embodiment includes a tubular cathode body made of SrTiO3 ceramics, the side of the cathode body is a rough surface, and the side of the cathode body is attached with an emission layer made of carbon nanotubes. The thickness of the emission layer is 0.5mm, and SiO2-B2O-ZnO glass powder is added, and the cathode body and the emission layer are co-sintered to form.

[0066] A method for preparing a high-current repetition frequency strontium titanate-carbon nanotube dielectric cathode in this embodiment includes the following steps:

[0067] Step a: use concentrated nitric acid to carry out carboxylation enhanced activity treatment to carbon nanotubes, and add 0.5% and cellulose; Mix carbon nanotubes and 3% terpineol, grind and make the first slurry; SiO2-B2O -ZnO glass powder and 3% terpineol were mixed and ground to obtain the second slurry; the first slurry and the second ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com