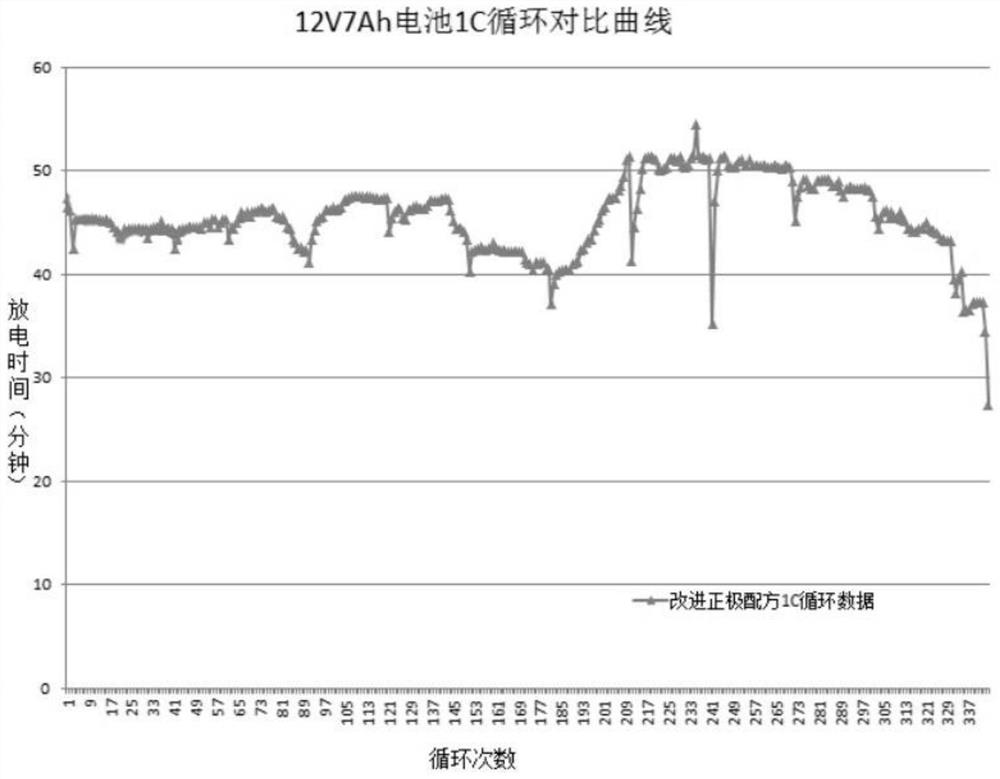

A positive electrode additive for improving the service life of valve-regulated sealed lead-acid battery and its application

A lead-acid battery and additive technology, applied in lead-acid battery electrodes, lead-acid batteries, battery electrodes, etc., can solve problems such as shortening the service life of valve-regulated sealed lead-acid batteries and prone to high impedance layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] An application of a positive electrode additive for improving the service life of a valve-regulated sealed lead-acid battery, the positive electrode additive is used to prepare lead paste, and the lead paste is composed of the following parts by weight of each raw material: 80 parts of lead powder (content of lead oxide 71wt%), 1.25 parts of positive additive, 7 parts of sulfuric acid (density is 1.40g / cm 3 ), 9 parts of deionized water, the positive electrode additive includes the following mass fractions of each raw material: 35% bismuth oxide, 12% polypropylene fiber, 30% tetrabasic lead sulfate, 23% diatomaceous earth, the lead paste is The preparation steps are as follows:

[0023] S1: Weigh lead powder and positive electrode additives, add them into the paste machine and stir and mix for 6 minutes;

[0024] S2: Add enough deionized water to the blender, stir and mix for 5min;

[0025] S3: Add sulfuric acid into the mixing paste machine, control the speed of addi...

Embodiment 2

[0029] An application of a positive electrode additive for improving the service life of a valve-regulated sealed lead-acid battery, the positive electrode additive is used for preparing lead paste, and the lead paste is composed of the following raw materials in parts by weight: 85 parts of lead powder (content of lead oxide 71wt%), 2.5 parts of positive electrode additives, 8 parts of sulfuric acid (density is 1.40g / cm 3 ), 10 parts of deionized water, the positive electrode additive includes the following raw materials by mass fraction: 40% bismuth oxide, 10% polypropylene fiber, 32% tetrabasic lead sulfate, 18% diatomaceous earth, the lead paste is The preparation steps are as follows:

[0030] S1: Weigh lead powder and positive electrode additives, add them into the paste machine and stir and mix for 8min;

[0031] S2: Add enough deionized water to the blender, stir and mix for 6min;

[0032] S3: Add sulfuric acid into the mixing paste machine, control the speed of addi...

Embodiment 3

[0036] An application of a positive electrode additive for improving the service life of a valve-regulated sealed lead-acid battery, the positive electrode additive is used to prepare lead paste, and the lead paste is composed of the following parts by weight of each raw material: 90 parts of lead powder (content of lead oxide 71wt%), 3.5 parts of positive electrode additives, 10 parts of sulfuric acid (density is 1.40g / cm 3 ), 12 parts of deionized water, the positive electrode additive includes the following raw materials in mass fractions: 45% bismuth oxide, 8% polypropylene fiber, 28% tetrabasic lead sulfate, 19% diatomaceous earth, the lead paste is The preparation steps are as follows:

[0037] S1: Weigh lead powder and positive electrode additives, add them into the paste machine and stir and mix for 10min;

[0038] S2: Add enough deionized water to the blender, stir and mix for 8min;

[0039] S3: Add sulfuric acid into the mixing paste machine, control the speed of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com