Oral membrane and preparation method thereof

A technology of oral paste and drug loading, applied in the field of medicine, can solve the problems of being easily affected by oral movement, drinking water and eating, unable to provide effective protection, and easily affected by oral movement, so as to promote wound healing and not easy to fall off , The effect of improving the comfort of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

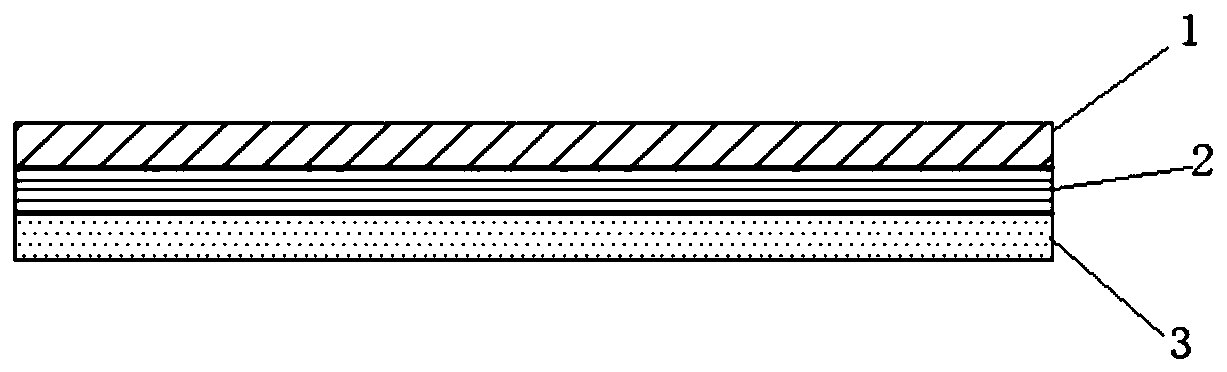

[0036] refer to figure 1 As shown, an oral patch in this embodiment includes a drug-loaded adhesive layer 3 , an extension layer 2 , and a hydrophobic protective layer 1 that are arranged sequentially.

[0037] Among them, the weight ratio of the drug-loaded adhesive layer 3, the extension layer 2, and the hydrophobic protective layer 1 is 37.5:38:24.5; the total thickness of the oral film is 0.3 mm;

[0038] The drug-loaded adhesive layer 3 in a kind of oral film of this embodiment is made of the following raw materials: 3.5kg of adhesive, 100g of drug-loaded substance A, 20g of flavoring agent, 30g of essence, 100g of release agent, deionized 40.25kg of water.

[0039] In this embodiment, the stretching layer 2 in the oral film is made of the following raw materials: 3.8 kg of stretching agent.

[0040] In this embodiment, the hydrophobic protective layer 1 in an oral film is made of 2.45 kg of ethyl cellulose.

[0041] The adhesive agent in a kind of oral patch of this e...

Embodiment 2

[0058] refer to figure 1 As shown, an oral patch in this embodiment includes a drug-loaded adhesive layer 3 , an extension layer 2 , and a hydrophobic protective layer 1 that are arranged sequentially.

[0059] Among them, the weight ratio of the drug-loaded adhesive layer 3, the extension layer 2, and the hydrophobic protective layer 1 is 50:13:48; the total thickness of the oral film is 0.3 mm;

[0060] The drug-loaded adhesive layer 3 in a kind of oral film in this embodiment is made of the following raw materials: 3.8kg of adhesive, 500g of drug-loaded substance A, 100g of flavoring agent, 30g of essence, 500g of release agent, deionized 38kg of water.

[0061] The stretching layer 2 in an oral patch in this embodiment is made of the following raw materials: 1.2 kg of stretching agent and 0.1 kg of drug-loaded substance B.

[0062] In this embodiment, the hydrophobic protective layer 1 in an oral film is made of 4.8 kg of ethyl cellulose.

[0063] The adhesive agent in ...

Embodiment 3

[0082] refer to figure 1 As shown, an oral patch in this embodiment includes a drug-loaded adhesive layer 3 , an extension layer 2 , and a hydrophobic protective layer 1 that are arranged sequentially.

[0083] Among them, the weight ratio of the drug-loaded adhesive layer 3, the extension layer 2, and the hydrophobic protective layer 1 is 37.5:38:24.5; the total thickness of the oral film is 0.3mm;

[0084] The drug-loaded adhesive layer 3 in a kind of oral film of this embodiment is made of the following raw materials: 2.1 kg of adhesive, 50 g of drug-loaded substance A, 10 g of flavoring agent, 10 g of essence, 50 g of release agent, deionized 21.2kg of water.

[0085] In this embodiment, the stretching layer 2 in an oral film is made of the following raw materials: 1.7 kg of stretching agent.

[0086] In this embodiment, the hydrophobic protective layer 1 in an oral patch is made of 1.9 kg of ethyl cellulose.

[0087] The adhesive agent in a kind of oral patch of this e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com