Preparation process of high-binding-force porous laser welding sheet

A preparation process and laser welding technology, which is applied in the field of preparation process of porous laser welding sheets, can solve problems such as difficult to maintain safety and stability, and achieve the effects of improving cutting efficiency, high blade height, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

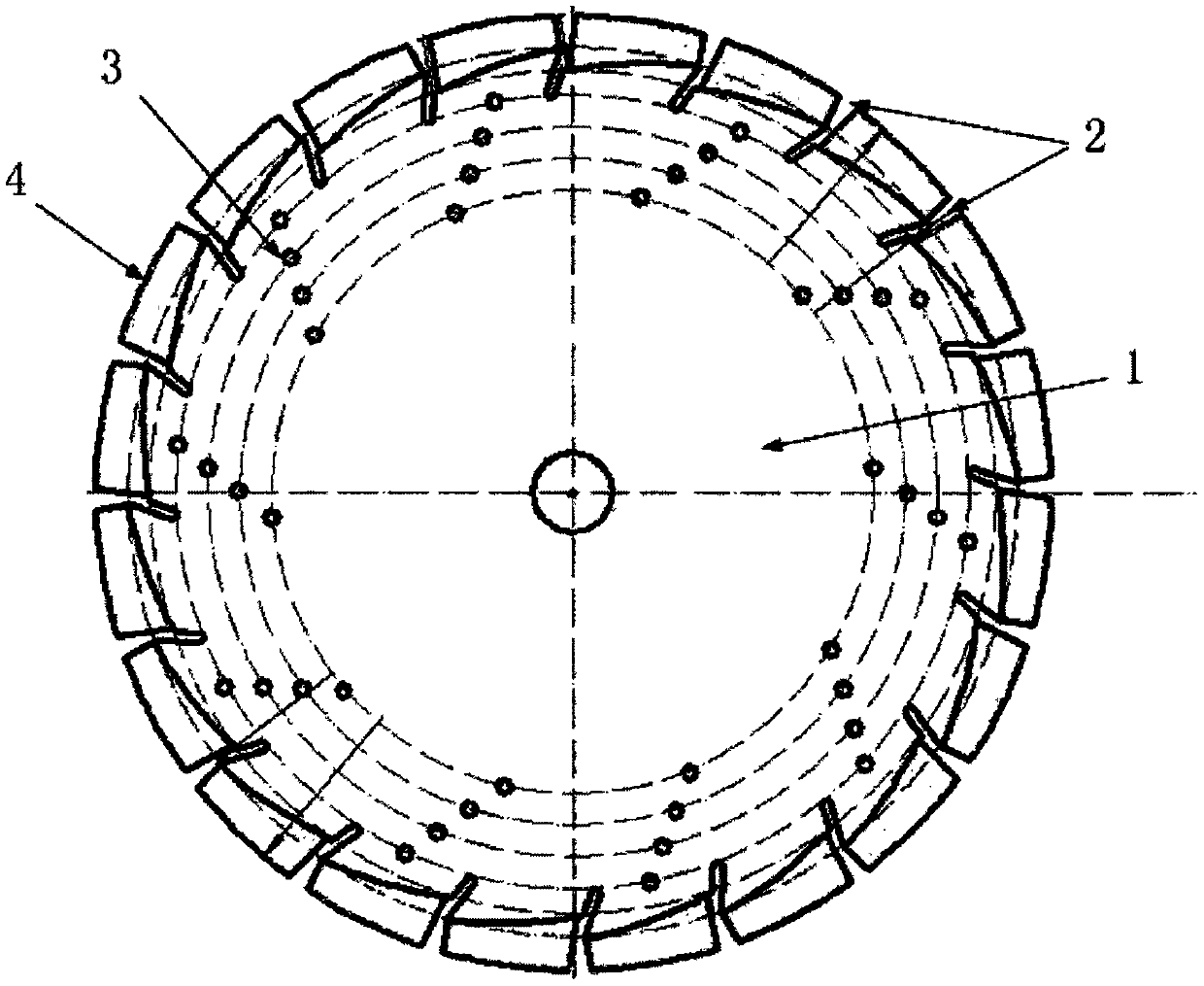

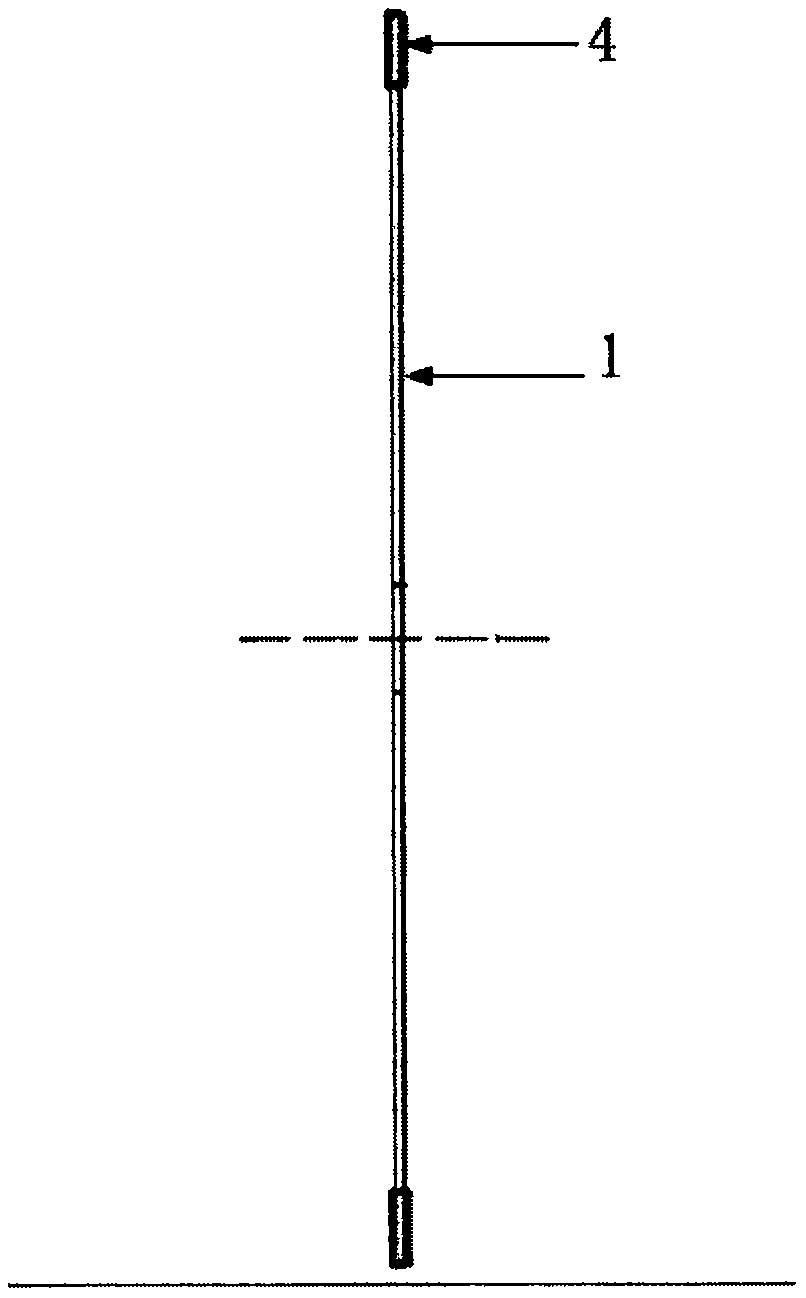

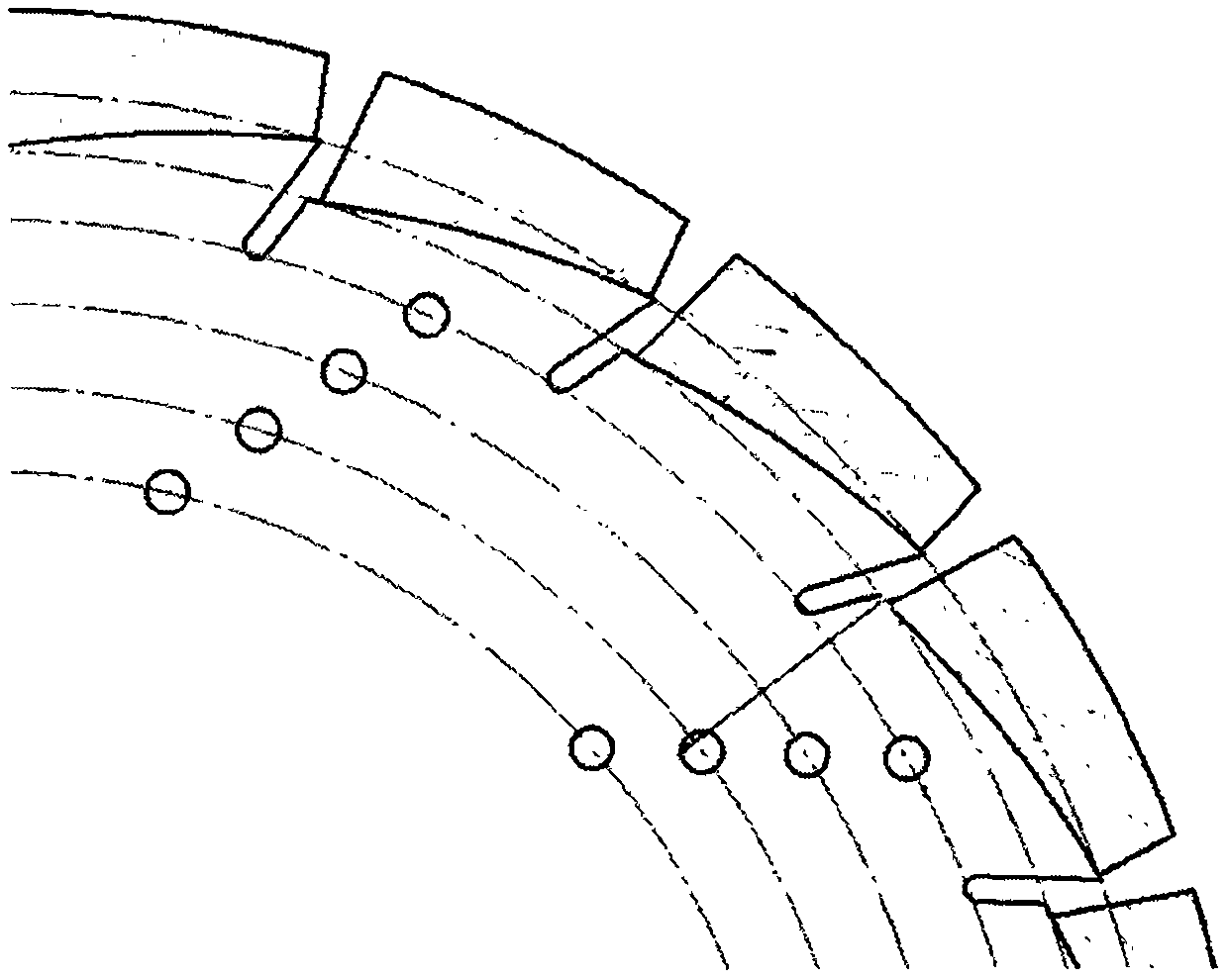

Image

Examples

Embodiment 1

[0039] This embodiment is the preparation of porous laser welding sheet for mouthguard, the process is as follows:

[0040] 1. The base material is 30CrMo; the raw material composition of the cutter head is as follows (parts by weight):

[0041] 24 parts of copper, 31 parts of iron, 7.5 parts of nickel, 12 parts of cobalt, 6 parts of tin, 19.5 parts of rare earth alloy, 0.14 parts of liquid paraffin, and 1.6 parts of diamond.

[0042] The diamond particle size is 40 / 50, and the compressive strength is 25-40kg; the rare earth alloy is a La-Ni alloy, and the La in the La-Ni alloy is 15.5wt.%, and the balance is Ni.

[0043] 2. Substrate processing:

[0044] The steel plate is heat treated. The heat treatment process is: oil quenching at 870 degrees for 12 minutes, and then tempering at 460 degrees for 4 hours; the steel plate after heat treatment is processed into the shape of the matrix;

[0045] 3. Preparation of diamond cutter head:

[0046]The raw materials of the diamond...

Embodiment 2

[0053] This embodiment is the preparation of porous laser welding sheet for mouthguard, the process is as follows:

[0054] 1. The base material is 30CrMo; the raw material composition of the cutter head is as follows (parts by weight):

[0055] 25.5 parts of copper, 34 parts of iron, 8 parts of nickel, 12 parts of cobalt, 4.5 parts of tin, 20 parts of rare earth alloys, 0.12 parts of liquid paraffin, and 1.5 parts of diamond.

[0056] The diamond particle size is 40 / 50, and the compressive strength is 25-40kg; the rare earth alloy is a La-Ni alloy, and the La in the La-Ni alloy is 15.5wt.%, and the balance is Ni.

[0057] 2. Substrate processing:

[0058] The steel plate is heat treated. The heat treatment process is: oil quenching at 875 degrees for 10 minutes, and then tempering at 450 degrees for 4 hours; the steel plate after heat treatment is processed into the shape of the matrix;

[0059] 3. Preparation of diamond cutter head:

[0060] The raw materials of the diamo...

Embodiment 3

[0067] This embodiment is the preparation of porous laser welding sheet for mouthguard, the process is as follows:

[0068] 1. The base material is 30CrMo; the raw material composition of the cutter head is as follows (parts by weight):

[0069] 25 parts of copper, 36 parts of iron, 6.5 parts of nickel, 12 parts of cobalt, 4.5 parts of tin, 15 parts of rare earth alloys, 0.14 parts of liquid paraffin, and 1.5 parts of diamond.

[0070] The diamond particle size is 40 / 50, and the compressive strength is 25-40kg; the rare earth alloy is a La-Ni alloy, and the La in the La-Ni alloy is 15.5wt.%, and the balance is Ni.

[0071] 2. Substrate processing:

[0072] The steel plate is heat treated. The heat treatment process is: oil quenching at 875 degrees for 12 minutes, and then tempering at 480 degrees for 4 hours; the steel plate after heat treatment is processed into the shape of the matrix;

[0073] 3. Preparation of diamond cutter head:

[0074] The raw materials of the diamo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com