Transfer printing method and application

A technology of transfer printing and graphic layer, applied in the direction of copying/marking method, printing, etc., can solve the problems of high adhesion coefficient between the interface between two substrates and graphic layer, inability of graphic layer to be damaged, peeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

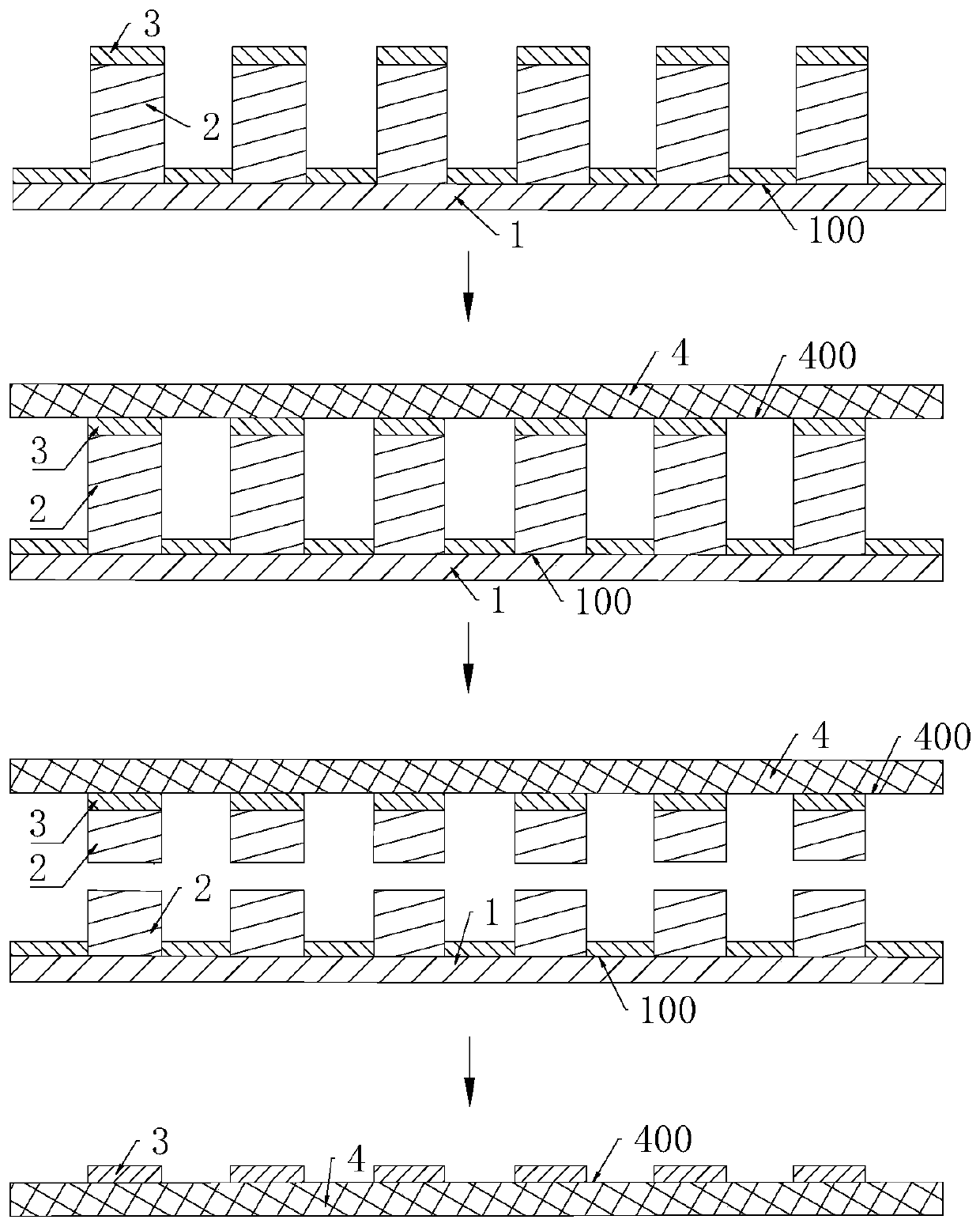

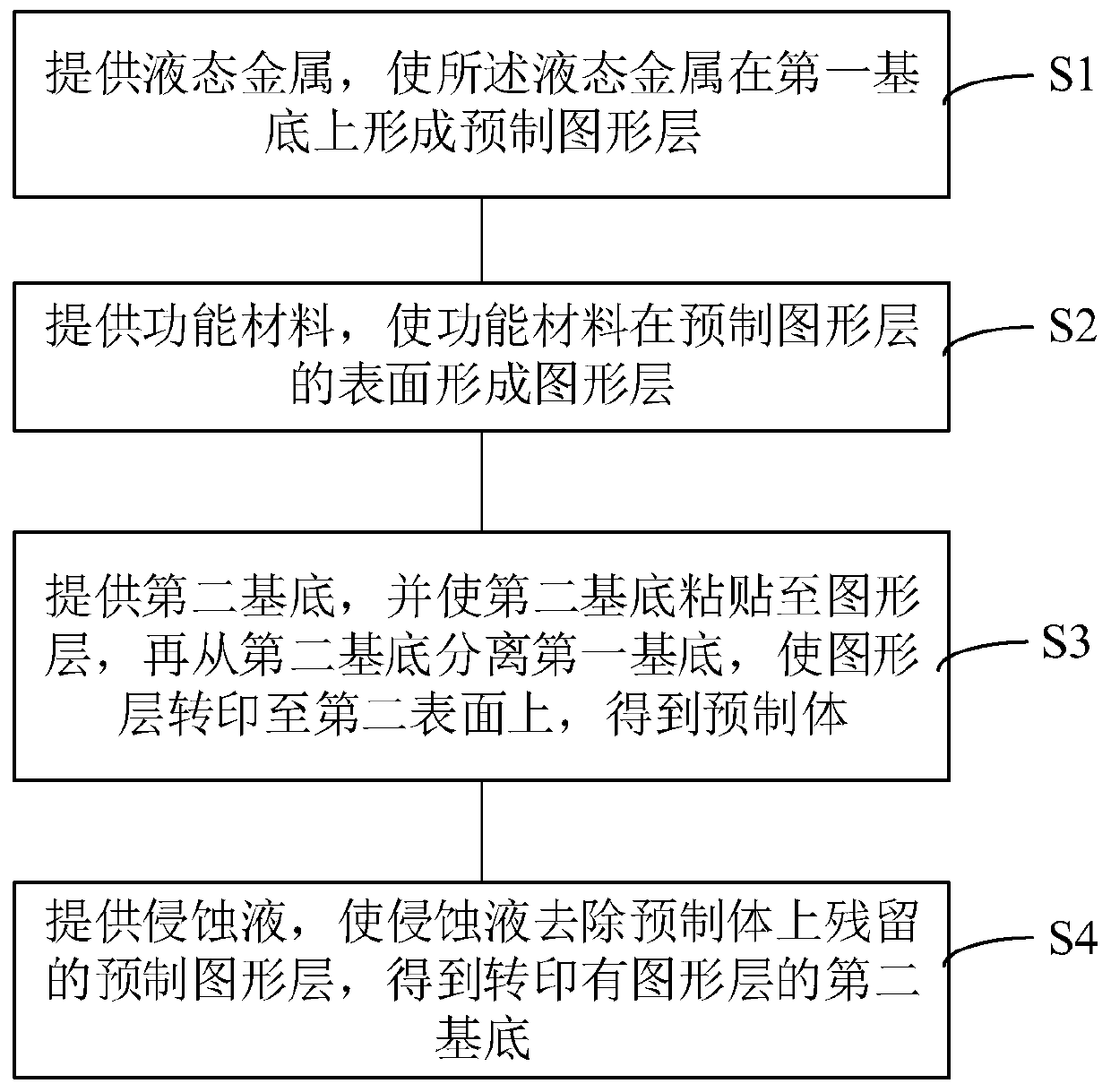

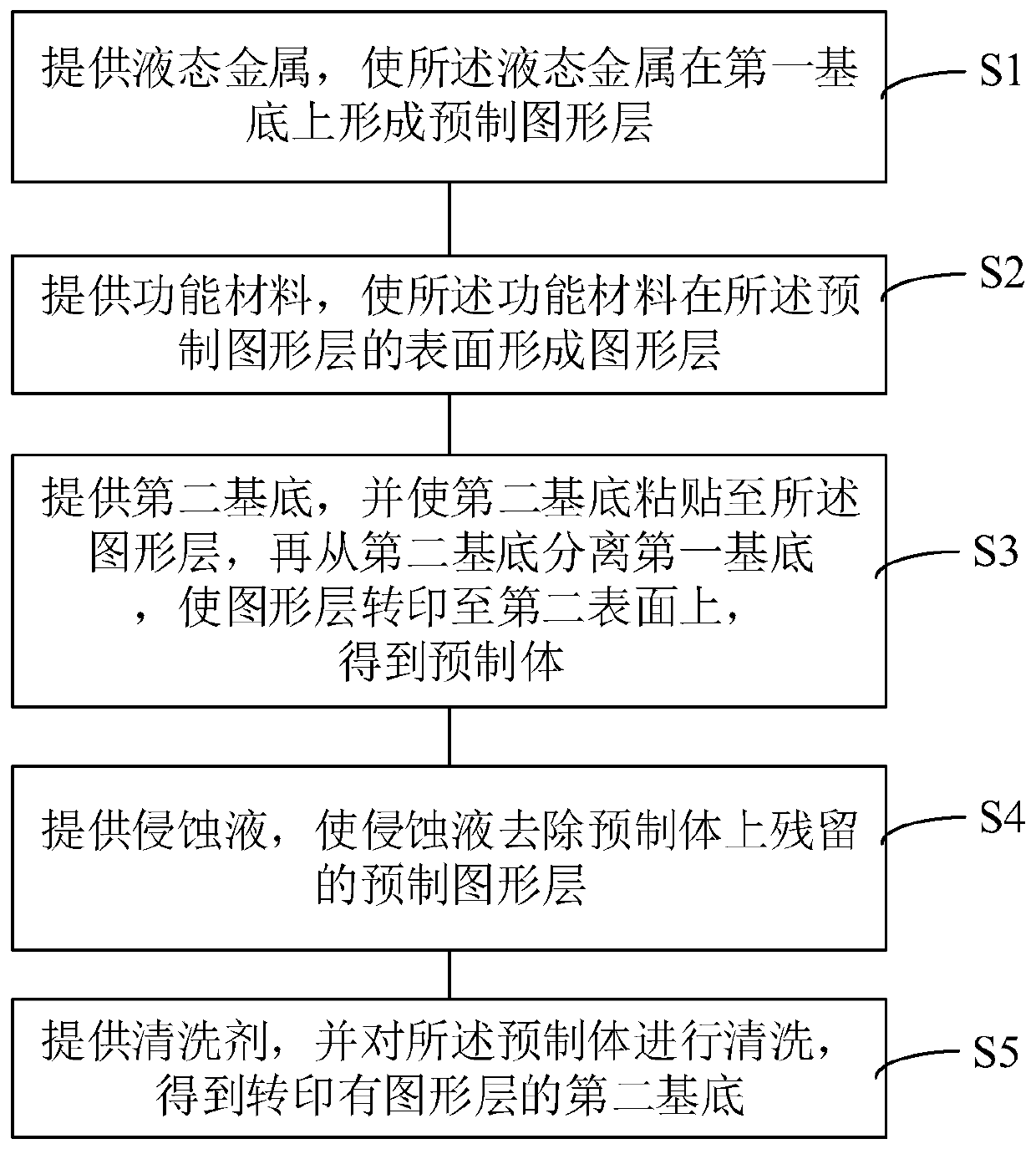

[0042] In the preparation method provided by the present invention, the liquid metal is formed on the first surface 100 of the first substrate 1 to form the pre-patterned layer 2, and the pre-patterned layer 2 includes the oxide of the liquid metal formed on the surface of the liquid metal. Wherein, the interfacial binding force between the liquid metal and the first surface 100 of the first substrate 1 is relatively small, so it can be easily transferred or separated from the first substrate 1; the oxide of the liquid metal and the oxide formed on The graphic layers 3 on the prefabricated graphic layer 2 can be connected by chemical bonds, thus having a strong bonding force; and the adhesive force between the graphic layer 3 and the second substrate 4 is greater than that between the liquid metal and the first Interfacial bonding force between substrates 1. In this way, during the separation process of the first substrate 1 and the second substrate 4, the prefabricated patter...

Embodiment 1

[0087] Place the gallium indium alloy in an oxygen-enriched environment for 30s and stir it, and use it as a raw material to print on the surface of the magnesium alloy substrate by 3D printing to form a prefabricated pattern layer. In the prefabricated pattern layer, the oxide of the gallium indium alloy and the The mass ratio of gallium-indium alloy is approximately 1:200, that is, only a small amount of gallium-indium alloy is controlled to undergo oxidation reaction.

[0088] The thickness of the prefabricated pattern layer is approximately 10 μm, and the gold particles are deposited on the surface of the prefabricated pattern layer by magnetron sputtering to form a pattern layer, and the thickness of the pattern layer is 10 nm;

[0089] The magnesium alloy substrate with the patterned layer deposited is taken out from the deposition chamber, and the polyimide substrate is pasted on the surface of the patterned layer deposited on the magnesium alloy substrate, and then the ...

Embodiment 2

[0093] Put the gallium indium tin alloy in the air for 30 minutes and stir it, and use it as a raw material to form a prefabricated pattern layer by spraying on the surface of the polydimethylsiloxane base, and the oxidation of the gallium indium tin alloy in the prefabricated pattern layer The mass ratio of the compound to the gallium indium tin alloy is 1:50;

[0094] The thickness of the prefabricated pattern layer is 200 μm, and titanium oxide is deposited on the surface of the prefabricated pattern layer by chemical vapor deposition to form a pattern layer, and the thickness of the pattern layer is 100 μm;

[0095] The polydimethylsiloxane substrate with the pattern layer deposited is taken out from the deposition chamber, and the polyethylene terephthalate substrate is pasted on the surface of the polydimethylsiloxane substrate deposition pattern layer side, and then provided intercalation agent, and separate the polydimethylsiloxane substrate and the polyethylene tereph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com