Steel BG80MnCr for steel balls of ball mill and preparation method of steel

A ball mill and steel ball technology, applied in the field of ball mill steel ball manufacturing, can solve the problems of large rolling mill resistance, strict requirements on the carbon segregation index of steel, and high content of P and S, so as to reduce the influence of steel resistance and improve the ratio of equiaxed crystals , to meet the effect of high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

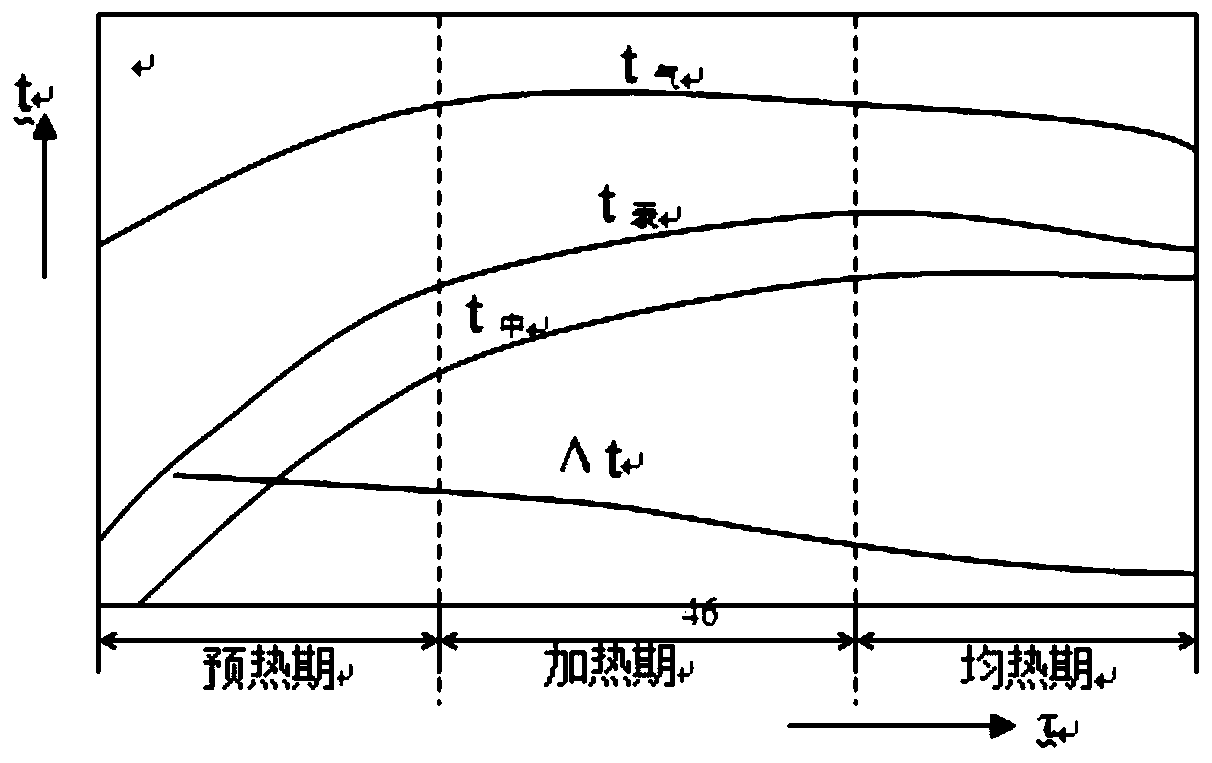

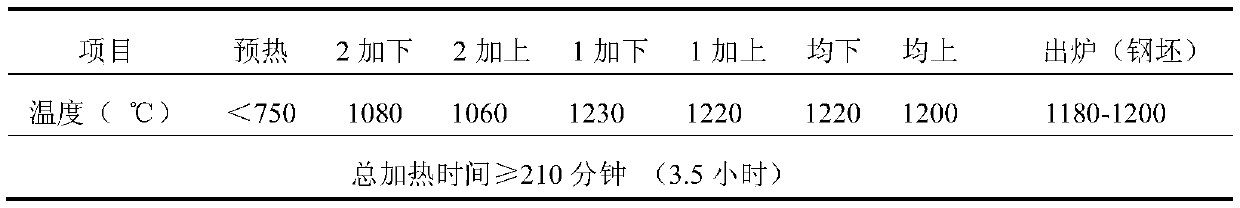

[0019] The present embodiment ball mill steel ball steel BG80MnCr electric furnace continuous casting production process flow is:

[0020] Blast furnace molten iron→hot metal pretreatment→50t electric arc furnace smelting→refining furnace LF→vacuum degassing VD→casting 235×265 medium billet→stepping furnace heating→high pressure water descaling→800 roughing mill rolling→continuous rolling mill→ Slow cooling → finishing → flaw detection → inspection → storage.

[0021] 1. Electric arc furnace smelting: In the electric arc furnace smelting molten steel step, scrap steel and molten iron are used as the charge. In terms of mass percentage, scrap steel accounts for 35% to 40%, and molten iron accounts for 60% to 65%; oxygen blows for 65 minutes to 70 minutes, and electrodes are powered for 10 minutes to 15 minutes. , violent boiling, automatic slag flow, decarburization weight 0.60% ~ 0.65%, C is 0.05 ~ 0.25% when tapping, P≤0.010%, tapping temperature 1660 ~ 1680 ℃, tapping 1 / 4 ~ ...

Embodiment 2

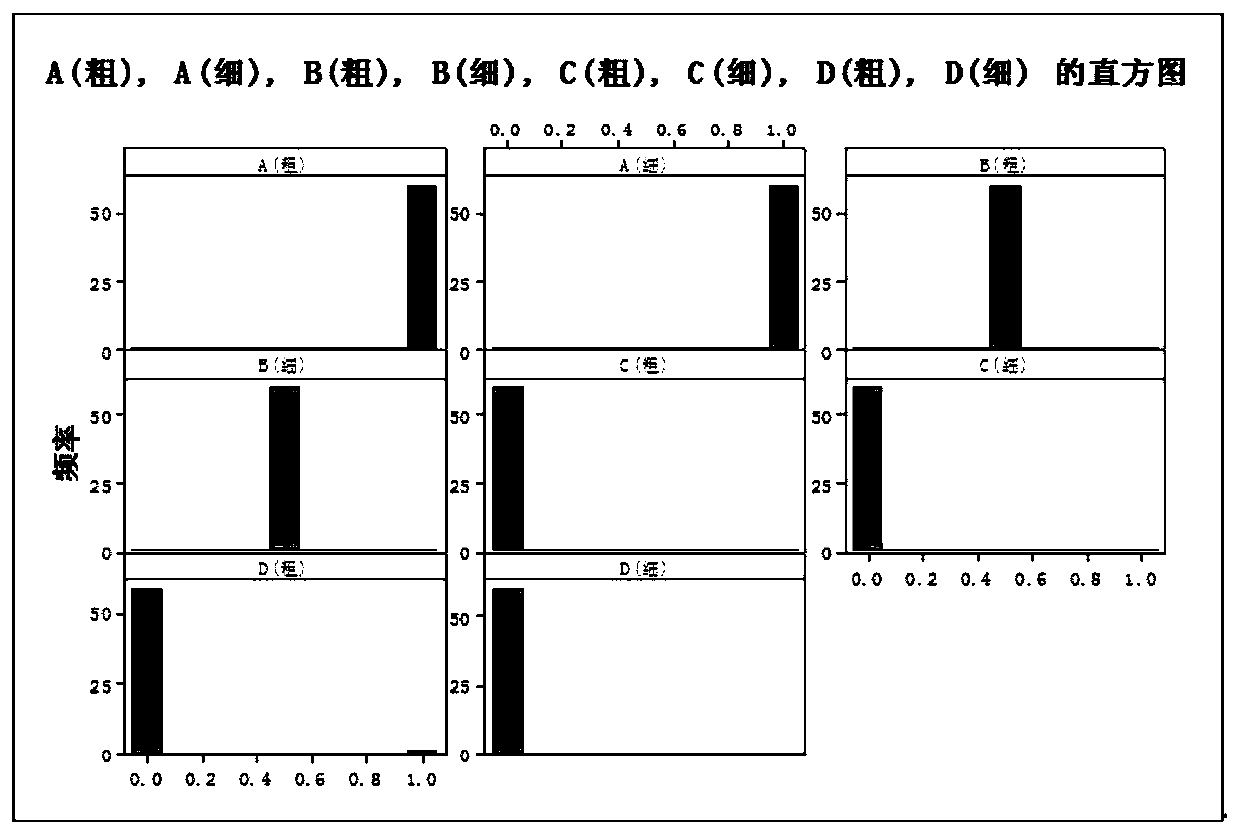

[0028] Narrow composition control for chemical composition

[0029]

[0030] Evaluate the carbon segregation index formula

[0031] Cut a transverse test piece from any steel, analyze the steel cross section center (code: Cz), 3 / 4 radius (code: Cb), 1 / 2 radius (code: Cc), 1 / 4 radius (code: Cd) The calculated carbon segregation meets the following requirements: 0.95≤3×Cz / (Cb+Cc+Cd)≤1.03.

[0032] 50t electric arc furnace + LF + VD + 235×265 medium billet + 800 continuous rolling process to produce BG80MnCr steel for ball mill steel balls, using continuous casting production, fast production pace, high yield, low cost, and many continuous casting furnaces.

[0033] The chemical composition is controlled by narrow composition to ensure the uniformity of the steel structure, long fatigue life, good wear resistance, and easy for customers to process and use.

[0034] Physical chemical composition%: C: 0.82, Si: 0.24, Mn: 0.74, P: 0.009, S: 0.004, Cr: 0.54, O: 0.0009, H: 0.0001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com