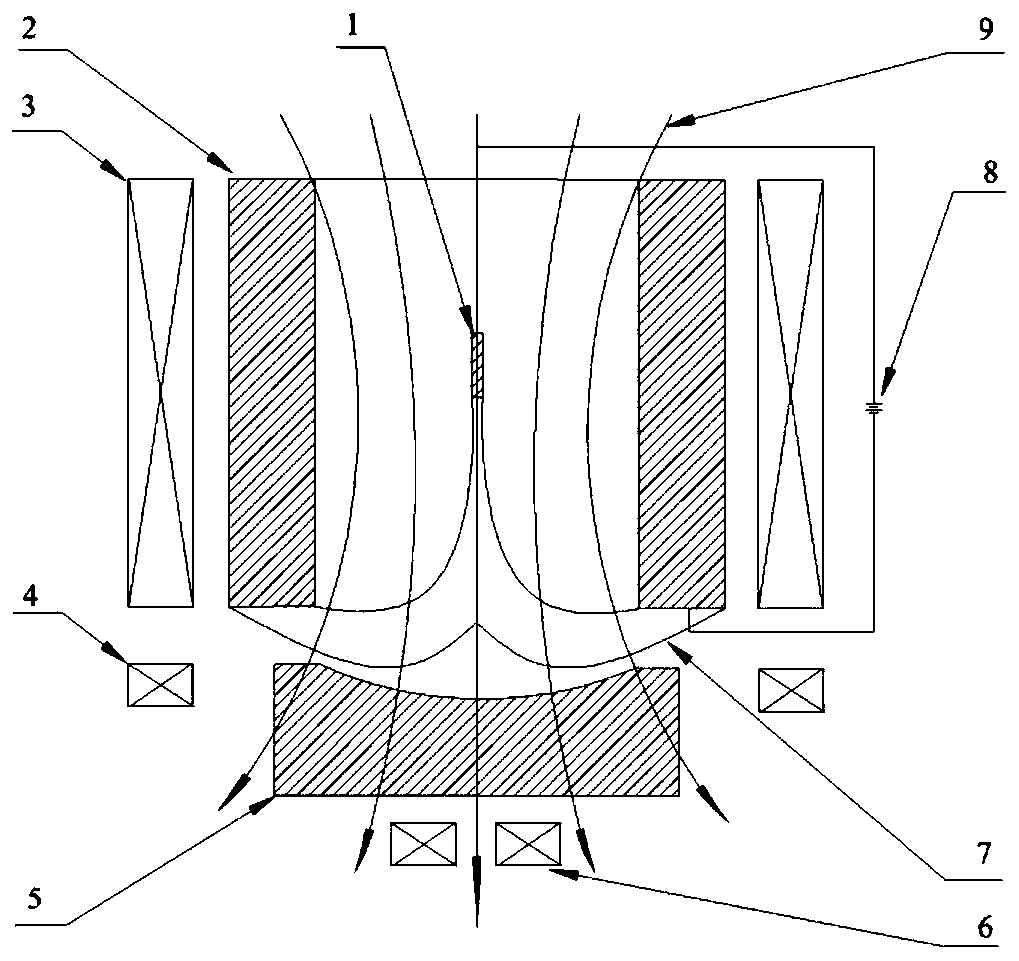

Plasma arc deposition device and method for diamond film

A technology of plasma and diamond film, applied in chemical instruments and methods, crystal growth, metal material coating technology, etc., can solve the problems of limited diamond size, rare natural diamond, containing catalyst impurities, etc., to eliminate uneven thickness, The effect of uniform plasma density and enlarged deposition area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Use a surface-treated conformal molybdenum substrate with a diameter of 150 mm, a circular depression at the center with a plane diameter of 100 mm and a center depth of 10 mm to prepare a diamond film in a plasma jet method with multi-level magnetic field control, and put the substrate in a vacuum The chamber is evacuated to an ultimate vacuum of 5×10 -1 Pa, gradually fill in argon gas to 5.2kPa, set the voltage of the stable arc magnetic field coil to 11.5V, set the voltage of the arc expansion magnetic field coil to 15V, set the voltage of the pilot arc magnetic field coil to 10V, and set the arc current of the plasma arc power supply to 135A , ignite the arc between the cathode and the anode, and fill in hydrogen gas (Ar:H 2 =0.8:1) Adjust the voltage of the stable arc magnetic field coil, the arc expanding magnetic field coil and the pilot arc magnetic field coil to make the arc rotate stably above the co-deposited substrate, increase the plasma arc power supply cu...

Embodiment 2

[0032] The diamond film is prepared in the plasma spraying method with multi-level magnetic field control on a conformal graphite substrate with a diameter of 180mm, a circular concave plane diameter of 140mm in the central position and a central depth of 12mm with a titanium transition layer surface treatment, and the substrate Put it into the vacuum chamber and pump it to the ultimate vacuum of 4.5×10 -1 Pa, gradually fill in argon gas to 4.2kPa, set the voltage of the stable arc magnetic field coil to 13.5V, set the voltage of the arc expansion magnetic field coil to 16V, set the voltage of the pilot arc magnetic field coil to 12V, and set the arc current of the plasma arc power supply to 125A , ignite the arc between the cathode and the anode, and fill in hydrogen gas (Ar:H 2 =0.8:1) Adjust the voltage of the stable arc magnetic field coil, the arc expanding magnetic field coil and the pilot arc magnetic field coil to make the arc rotate stably above the deposition substra...

Embodiment 3

[0034] Using a surface-treated conformal molybdenum substrate with a diameter of 180 mm, a central circular depression with a plane diameter of 140 mm, and a central depth of 12 mm, a diamond film was prepared in a plasma jet method with multi-level magnetic field control, and the substrate was placed in The vacuum chamber is pumped to an ultimate vacuum of 5×10 -1 Pa, gradually fill in argon gas to 5.2kPa, set the voltage of the stable arc magnetic field coil to 13.5V, set the voltage of the arc expansion magnetic field coil to 16V, set the voltage of the pilot arc magnetic field coil to 12V, and set the arc current of the plasma arc power supply to 130A , ignite the arc between the cathode and the anode, and fill in hydrogen gas (Ar:H 2 =0.8:1) Adjust the voltage of the stable arc magnetic field coil, the arc expanding magnetic field coil and the pilot arc magnetic field coil to make the arc rotate stably above the co-deposited substrate, increase the plasma arc power supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com