Preparation method of plant essential oil emulsion for inhibiting growth of fusarium graminearum

A technology for Fusarium graminearum and plant essential oil, which is applied in the field of preparation of plant essential oil emulsion, can solve the problems of small droplet aggregation, limited capacity, flocculation and sedimentation, etc., achieves good bacteriostatic effect, good inhibitory effect, and overcomes poor water solubility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 prepares clove oil emulsion

[0032] (1) Take 8mL of clove oil as the oil phase, dissolve the lecithin with a concentration of 1wt% in 10mM acetate buffer, and filter through a double-layer filter cloth to obtain an emulsifier solution;

[0033] (2) Take 92mL of the emulsifier solution prepared in step (1) and 8mL of clove oil and mix them. The mixing system is 100mL. Use a hand-held homogenizer to homogenize at 32000rpm for 2min, and then pass through a high-pressure homogenizer under a pressure of 1000bar. Circulate and homogenize at a rate of 9 L / h for 1 min to obtain clove oil emulsion.

Embodiment 2

[0034] Embodiment 2 prepares litsea cubeba oil emulsion

[0035] (1) Get 8mL litsea cubeba oil as the oil phase, dissolve the lecithin with a concentration of 1wt% in 10mM acetate buffer, and filter through a double-layer filter cloth to obtain an emulsifier solution;

[0036] (2) 92mL of the emulsifier solution prepared in step (1) and 8mL of Litsea cubeba oil were mixed, and the mixing system was 100mL, and was homogenized for 2min at 32000rpm using a hand-held homogenizer, and then passed through a high-pressure homogenizer under pressure. Circulation and homogenization at a rate of 9 L / h for 1 min at 1000 bar to obtain litsea cubeba oil emulsion.

Embodiment 3

[0037] Embodiment 3 changes homogeneous condition

[0038] (1) Get 8ml clove oil and 8ml litsea cubeba oil respectively as the oil phase, dissolve lecithin with a concentration of 1wt% in 10mM acetate buffer, and filter with a double-layer filter cloth to obtain an emulsifier solution;

[0039] (2) Take the emulsifier solution prepared in step (1), mix it with 8mL clove oil and 8mL Litsea cubeba oil respectively, the mixed system is 100mL, use a hand-held homogenizer to homogenize at 32000rpm for 2min, and then use 9L / Through the high-pressure homogenizer at a speed of h, a series of clove oil emulsion and litsea cubeba were obtained under five pressures (400, 700, 1000, 1300 and 1600bar) and three homogenization times (0.5, 1 and 1.5min). oil emulsion.

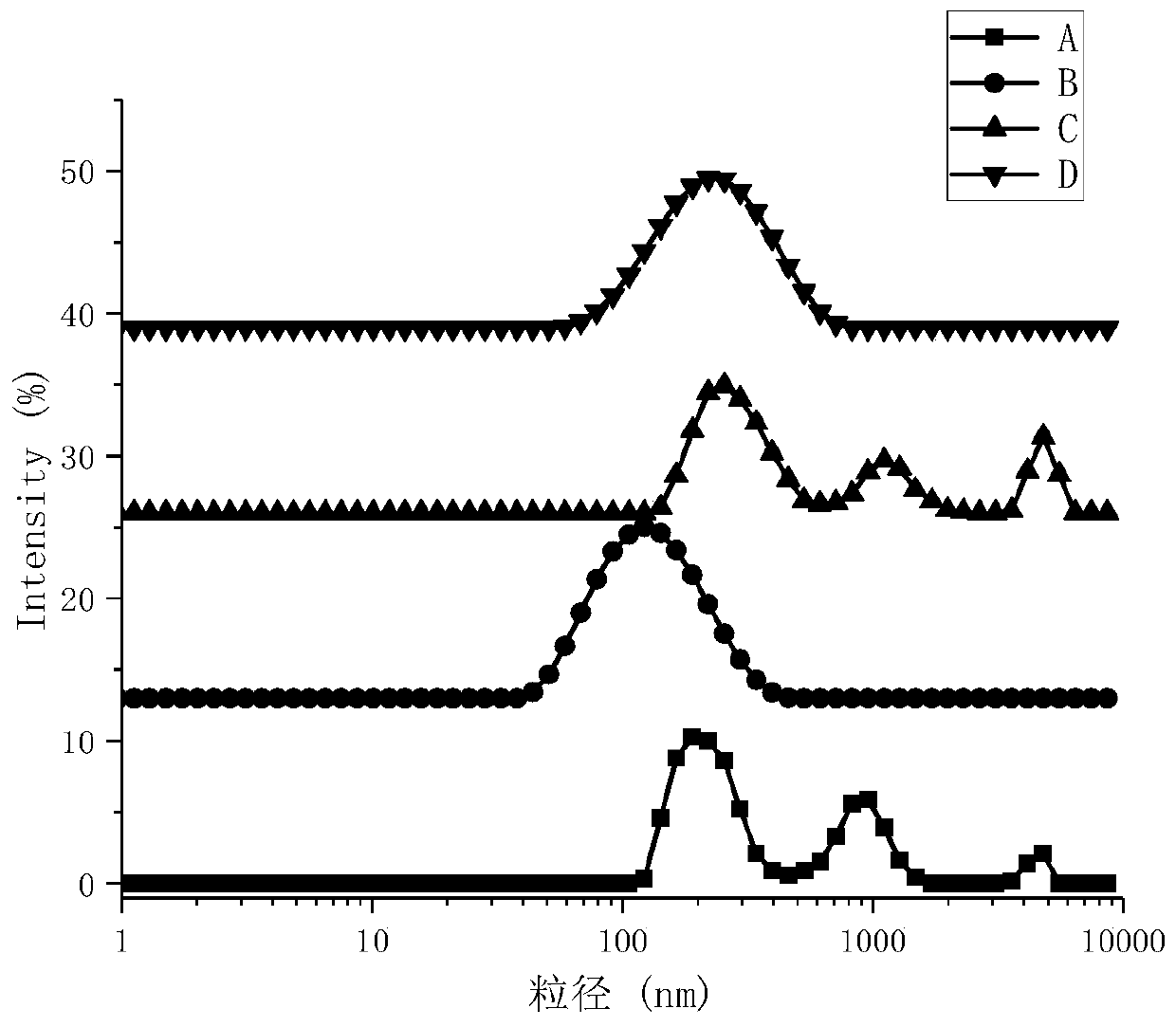

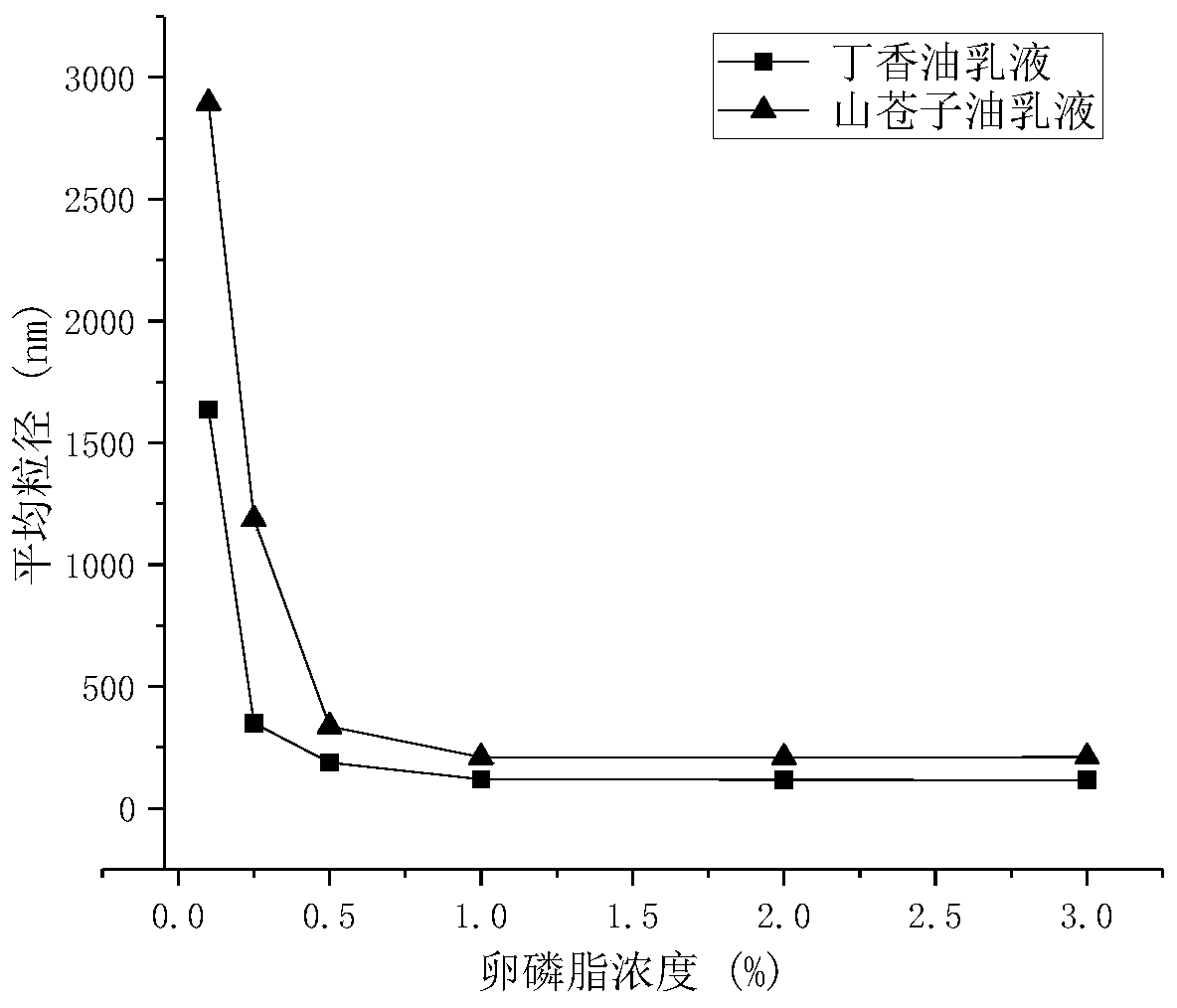

[0040] The average particle size of the emulsion obtained after different homogenization pressure and different homogenization time is shown in Table 1. The particle size distribution of clove oil emulsion and litsea cubeb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com