Hydrogel medical dressing for treating psoriasis and preparation method thereof

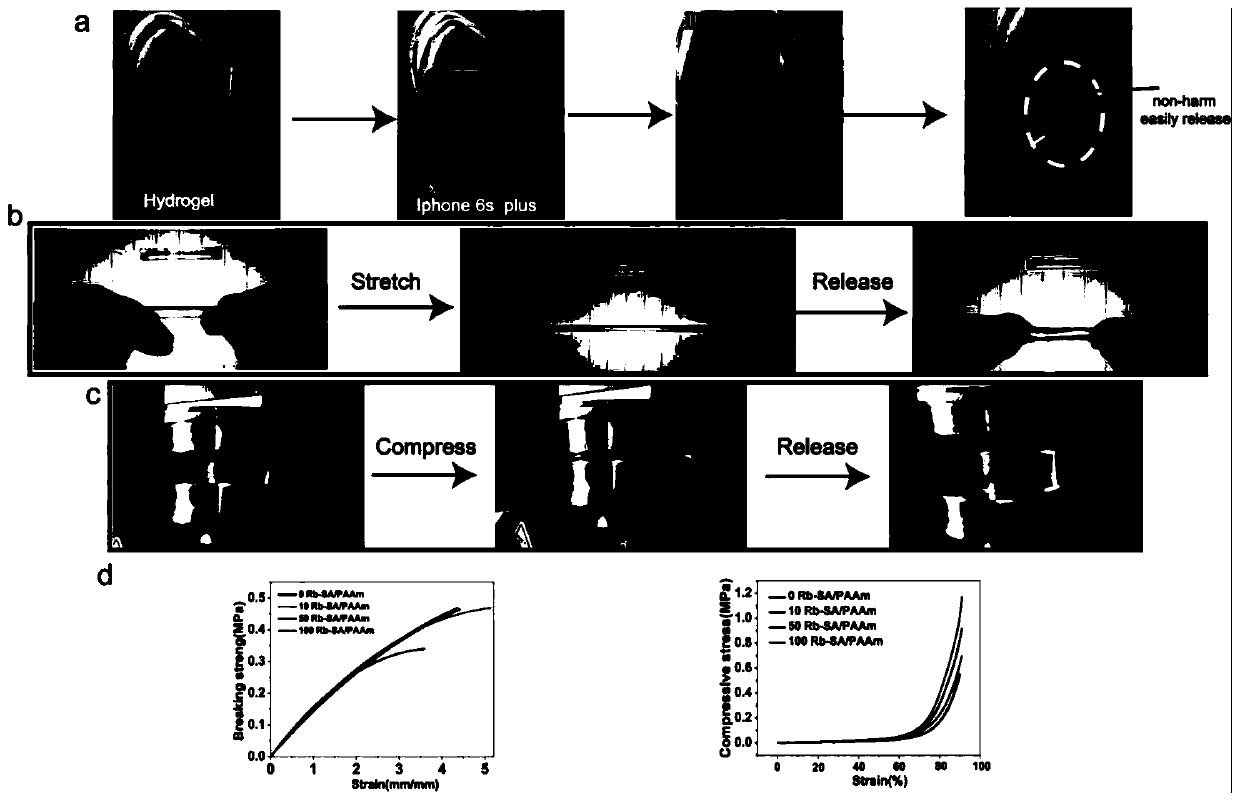

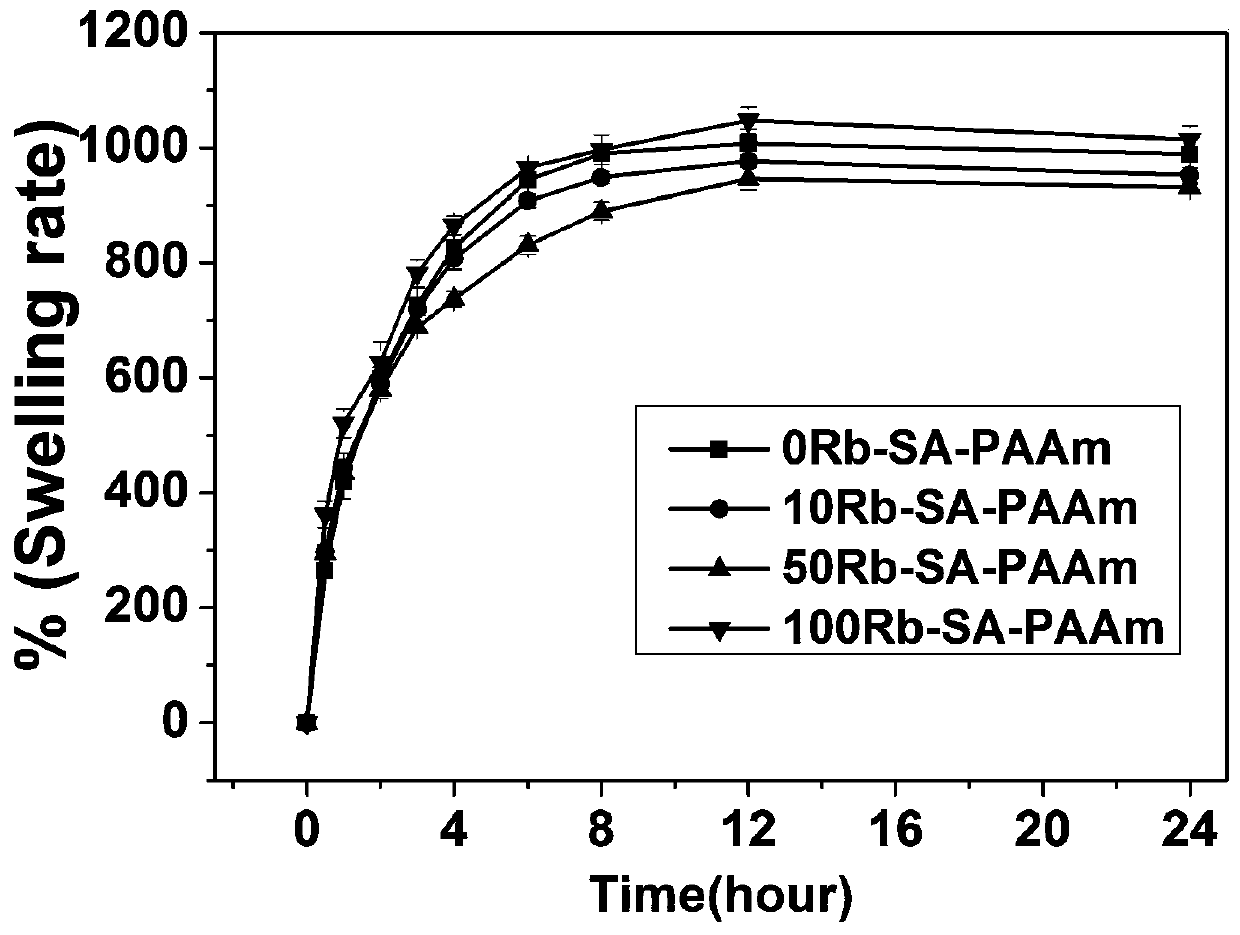

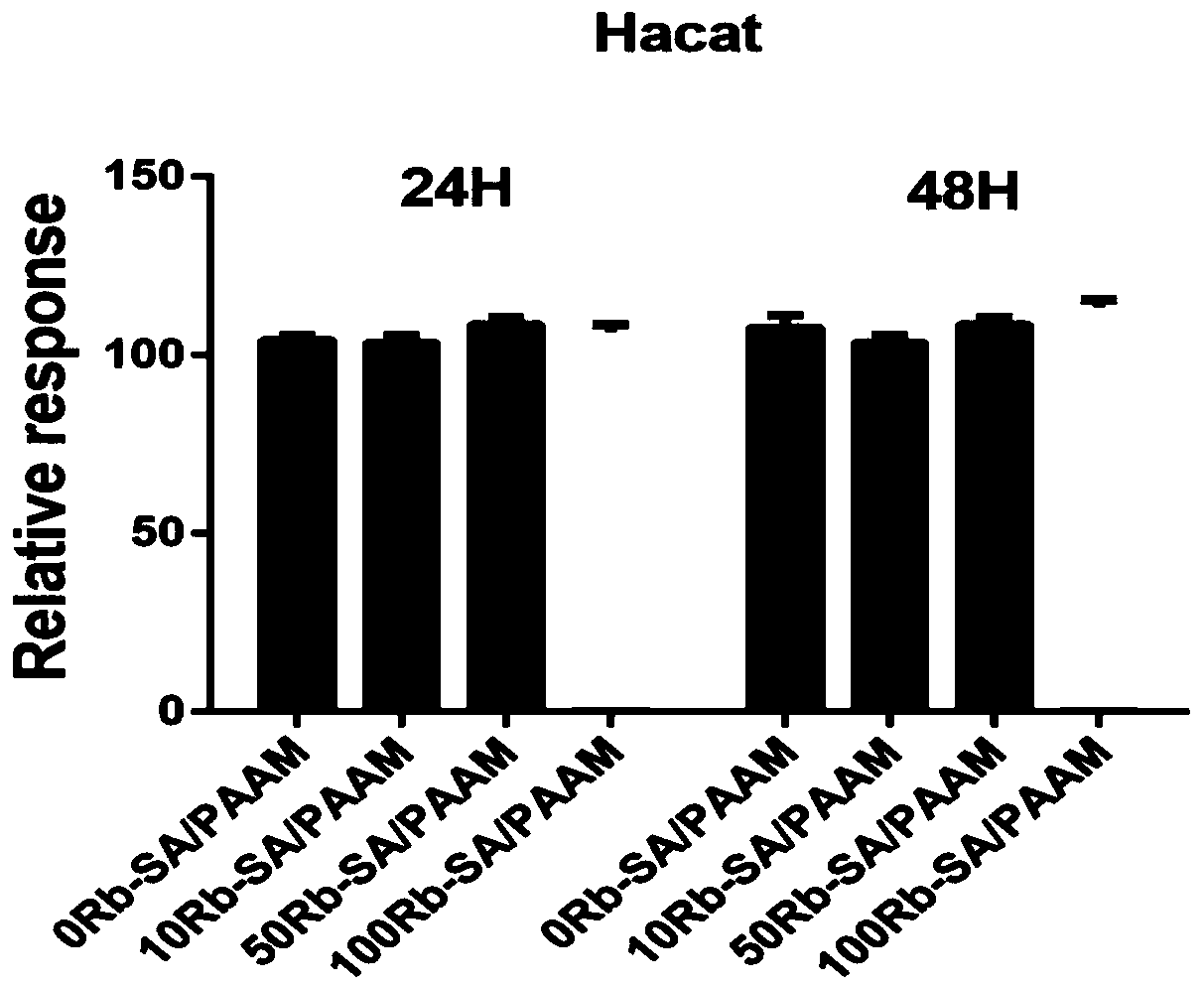

A hydrogel and psoriasis technology, applied in the field of topical psoriasis treatment materials, can solve problems such as high price and recurrence, and achieve the effects of reducing the expression of inflammatory factors, good elasticity, and safe and non-toxic ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Dissolve 0.4g of alginic acid and 0.1863g of rubidium chloride in 10ml of deionized water, and react with magnetic stirring for 30min at 30°C and a stirring speed of 400r / min (a large number of bubbles are generated during the reaction process, as the reaction time prolongs, Bubbles gradually disappear), to obtain rubidium alginate solution. Dissolve 0.2736g of sodium alginate in 9ml of deionized water to obtain a sodium alginate solution, then add 1ml of rubidium alginate solution to the sodium alginate solution, then stir magnetically at 40°C and 400r / min for 20min, Mix the two evenly to obtain an alginate solution. Put 1.68g of acrylamide, 0.65g of gluconolactone GDL, 0.1288g of basic magnesium carbonate, and 0.036g of basic zinc carbonate into the above-mentioned alginate solution (10ml), at 40°C and a stirring speed of 400r / min, Magnetic stirring was carried out for 30 minutes, and after uniform mixing, a pre-crosslinking solution was obtained. Add 0.01g of methy...

Embodiment 2

[0066] Dissolve 0.405g of alginic acid and 0.2794g of rubidium chloride in 15ml of deionized water, and react with magnetic stirring for 30min at 60°C and a stirring speed of 500r / min (a large number of bubbles are generated during the reaction process, as the reaction time prolongs, Bubbles gradually disappear), to obtain rubidium alginate solution. Dissolve 0.1520g of sodium alginate in 5ml of deionized water to obtain a sodium alginate solution, then add 5ml of rubidium alginate solution to the sodium alginate solution, then stir magnetically at 40°C and 600r / min for 20min, Mix the two evenly to obtain an alginate solution. Put 1.68g of acrylamide, 0.65g of gluconolactone GDL, 0.1288g of basic magnesium carbonate, and 0.036g of basic zinc carbonate into the above-mentioned alginate solution (10ml), at 40°C and a stirring speed of 400r / min, Magnetic stirring was carried out for 30 minutes, and after uniform mixing, a pre-crosslinking solution was obtained. Add 0.01g of met...

Embodiment 3

[0068] Dissolve 0.27g of alginic acid and 0.1831g of rubidium chloride in 10ml of deionized water, and react with magnetic stirring for 30min at 50°C and a stirring speed of 200r / min (a large number of bubbles are generated during the reaction process, as the reaction time prolongs, Bubbles gradually disappear), to obtain rubidium alginate solution. Put 1.68g of acrylamide, 0.65g of gluconolactone GDL, 0.1288g of magnesium carbonate, and 0.036g of basic zinc carbonate into the above-mentioned rubidium alginate solution (10ml) successively, at 20°C and a stirring speed of 800r / min, magnetically stir After 30 minutes, after mixing evenly, a pre-crosslinking solution was obtained. Add 0.01g of methylenebisacrylamide (MBAA), 10μl of tetramethylethylenediamine (TEMED), and 0.03g of ammonium persulfate (APS) to the above-mentioned pre-crosslinking solution (15ml) in sequence and heat at 500r / min Stir completely at a certain stirring speed, pour it into a glass container, irradiate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com