Preparation method of micro/nano fiber aerogel composite filter material

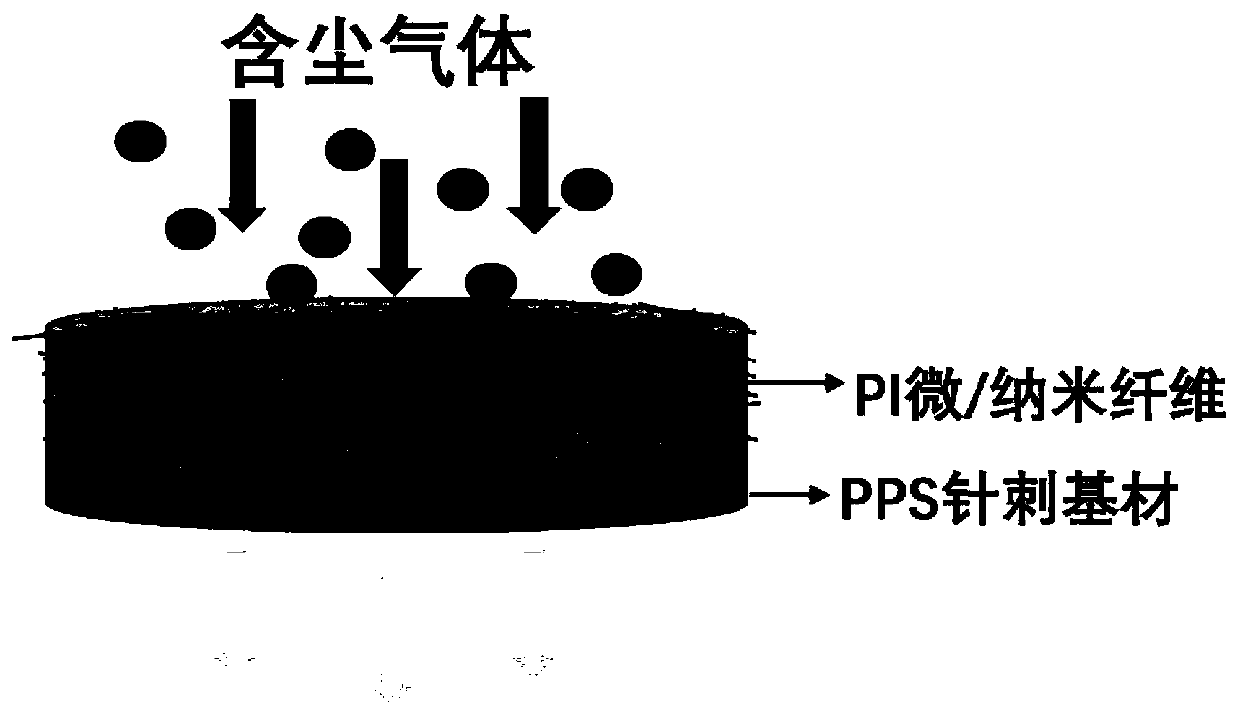

A technology of nanofiber and composite filter material, which is applied in the field of textile materials, can solve the problems such as the need to improve the particle filtration efficiency, achieve the effects of improving filtration efficiency, protecting the environment, and solving secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

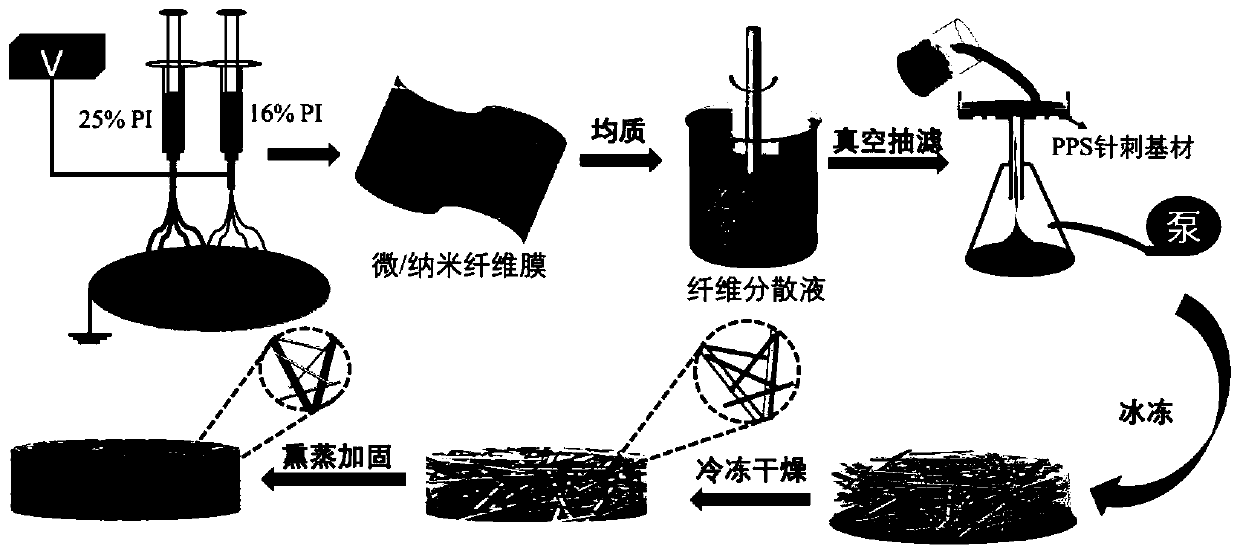

[0051] The preparation process of nano / micro fiber composite airgel filter material is as follows: figure 1 Shown: the preparation of the micro / nano high-temperature resistant fiber membrane, the preparation of the fiber dispersion, the freeze-drying of the substrate impregnated with the dispersion, and the reinforcement of the airgel composite filter material in sequence. The specific implementation is as follows:

[0052] A kind of micro / nano fiber airgel composite filter material, comprises following raw material:

[0053] P84 fiber; soluble polyimide (PI) powder; polyphenylene sulfide (PPS) needle-punched nonwoven substrate, 500g / m 2 ; N,N-dimethylformamide (DMF), N,N-dimethylacetamide (DMAc), dioxane.

[0054] (1) Preparation of micro / nano fibers:

[0055] Using multi-needle electrospinning technology, the PI spinning solution with a concentration of 16% and the PI spinning solution with a concentration of 25% are spun side by side, and the number ratio of 16% PI / 25% P...

Embodiment 2

[0063] A kind of micro / nano fiber airgel composite filter material, comprises following raw material:

[0064] P84 fiber; soluble polyimide (PI) powder; polyphenylene sulfide (PPS) needle-punched nonwoven substrate, 500g / m 2 ; N,N-dimethylformamide (DMF), N,N-dimethylacetamide (DMAc), dioxane.

[0065] (1) Preparation of micro / nano fibers:

[0066] Using multi-needle electrospinning technology, the PI spinning solution with a concentration of 10% and the PI spinning solution with a concentration of 25% are spun side by side, and the ratio of the number of 10% PI / 25% PI nozzles is 3:1. Among them, the PI spinning solution with a concentration of 10% is made of P84 fiber, and DMF is used as a spinning solution; the PI spinning solution with a concentration of 25% is made of soluble polyimide (PI) powder. Oxane:DMF=1:1 is the spinning solution. During the spinning process, the spinning voltage was 20 kV, the spinning distance was 20 cm, and the spinning flow rate was 1 mL / h. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com