Modified activated carbon for purifying formaldehyde and preparation method thereof

A technology of activated carbon and modification, which is applied in chemical instruments and methods, separation methods, and other chemical processes. It can solve the problems of application range and scene limitations, secondary air pollution, and low photocatalytic efficiency, so as to avoid safety problems. , Improve purification efficiency, long-term purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

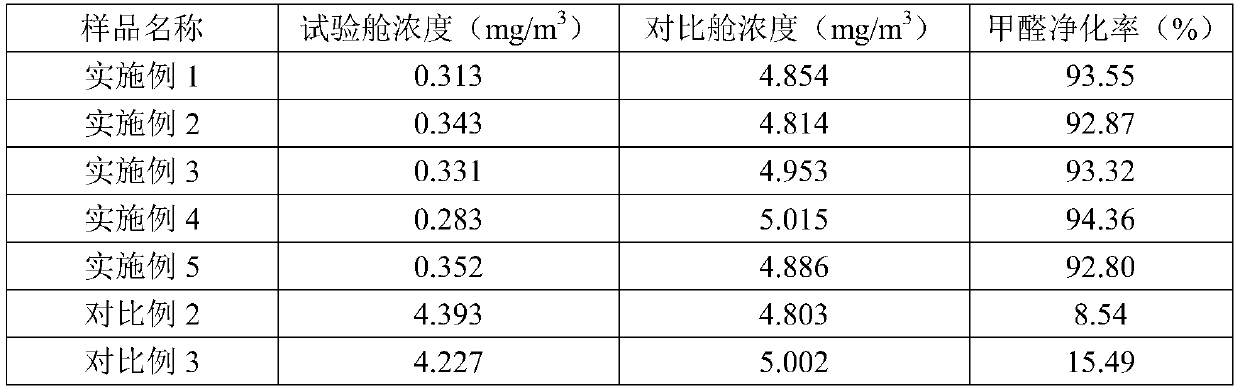

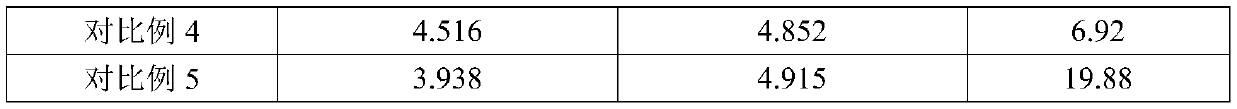

Examples

Embodiment 1

[0029] The present embodiment 1 provides a modified activated carbon for purifying formaldehyde and a preparation method thereof, comprising the following steps:

[0030] (1) Dry the coconut shell granular activated carbon at 160°C for 8 hours, and cool it in a desiccator for use;

[0031] (2) preparation mass concentration is the sodium hypochlorite solution of 0.5%;

[0032] (3) preparing a 2-imidazolidinone solution with a mass concentration of 2.0%;

[0033] (4) The sodium hypochlorite solution of step (2) is fully mixed with the activated carbon after drying by equal volume impregnation method, dried at room temperature for 36 hours, and dried in vacuum;

[0034] (5) The sodium hypochlorite modified activated carbon obtained in step (4) was then used for equal volume impregnation modification with the 2-imidazolidinone solution of (3), dried at room temperature for 60 hours, and dried in vacuum.

Embodiment 2

[0036] The present embodiment 2 provides a modified activated carbon for purifying formaldehyde and a preparation method thereof, comprising the following steps:

[0037] (1) Dry coconut shell granular activated carbon at 150°C for 10 hours, and cool it in a desiccator for use;

[0038] (2) preparation mass concentration is the sodium chlorate solution of 0.3%;

[0039] (3) preparation mass concentration is the ethylenediamine solution of 1.5%;

[0040] (4) the sodium chlorate solution of step (2) is fully mixed with the gac after drying by equal-volume impregnation method, dried at room temperature for 32 hours, and vacuum-dried;

[0041] (5) The sodium chlorate-modified activated carbon prepared in step (4) was impregnated with the ethylenediamine solution of (3) for equal volume modification, dried at room temperature for 55 hours, and vacuum-dried.

Embodiment 3

[0043] Present embodiment 3 provides a kind of preparation method of the modified activated carbon of purification formaldehyde, comprises the steps:

[0044] (1) Dry the coconut shell granular activated carbon at 170°C for 6 hours, and cool it in a desiccator for use;

[0045] (2) preparation mass concentration is the hydrogen peroxide solution of 1.0%;

[0046] (3) preparation mass concentration is the diethylamine solution of 4.0%;

[0047] (4) The hydrogen peroxide solution of step (2) is fully mixed with the activated carbon after drying by an equal-volume impregnation method, dried at room temperature for 42 hours, and vacuum-dried;

[0048] (5) The activated carbon modified by hydrogen peroxide obtained in step (4) was impregnated with an equal volume of the ethylenediamine solution of (3) for modification, dried at room temperature for 55 hours, and dried in vacuum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com