Frictional material and preparation method and purpose thereof

A technology of friction materials and raw materials, applied in friction linings, mechanical equipment, gear transmission mechanisms, etc., can solve the problems of poor material stability and consistency, improve the stability of friction coefficient, improve density, and ensure the stability of friction coefficient sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

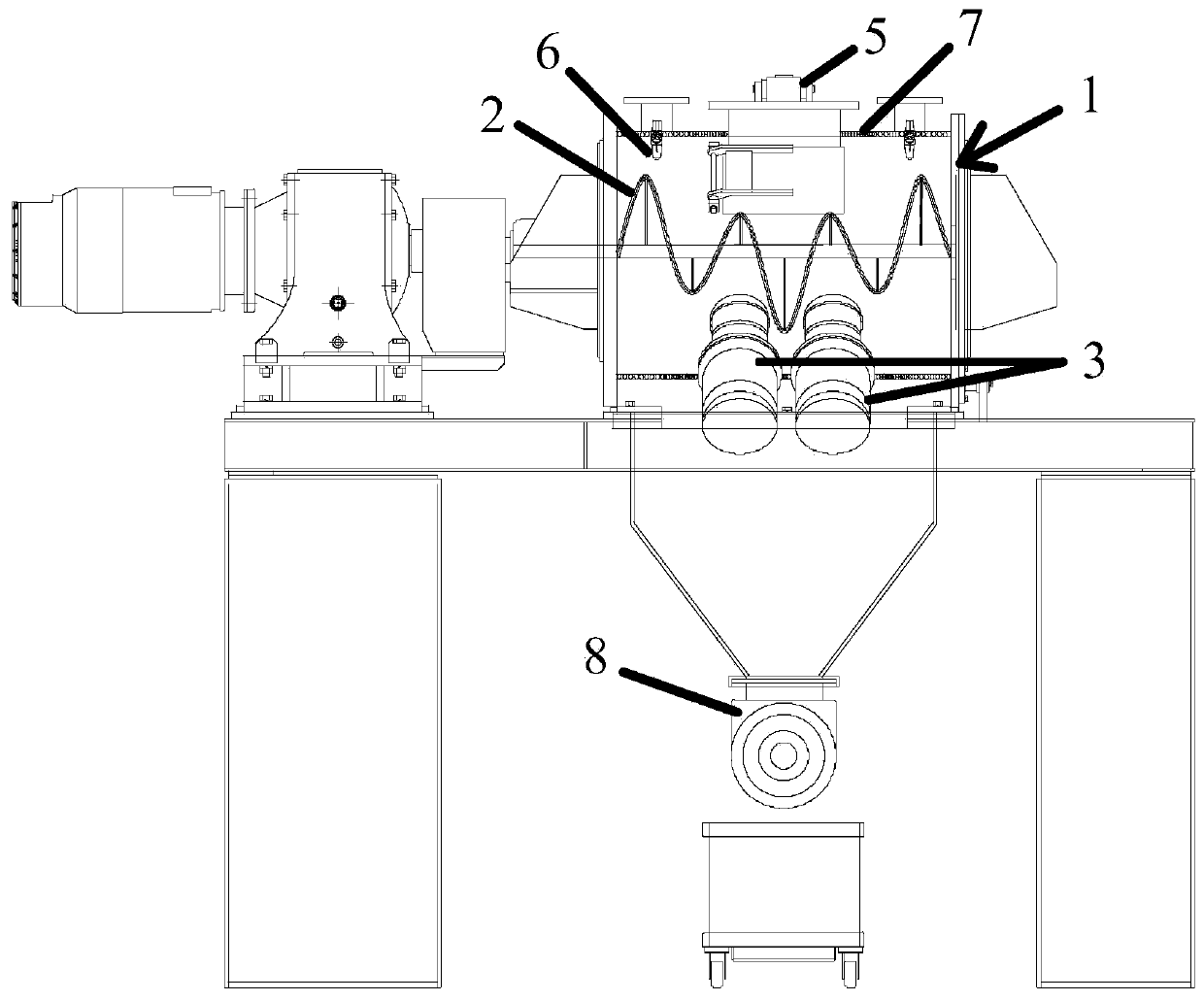

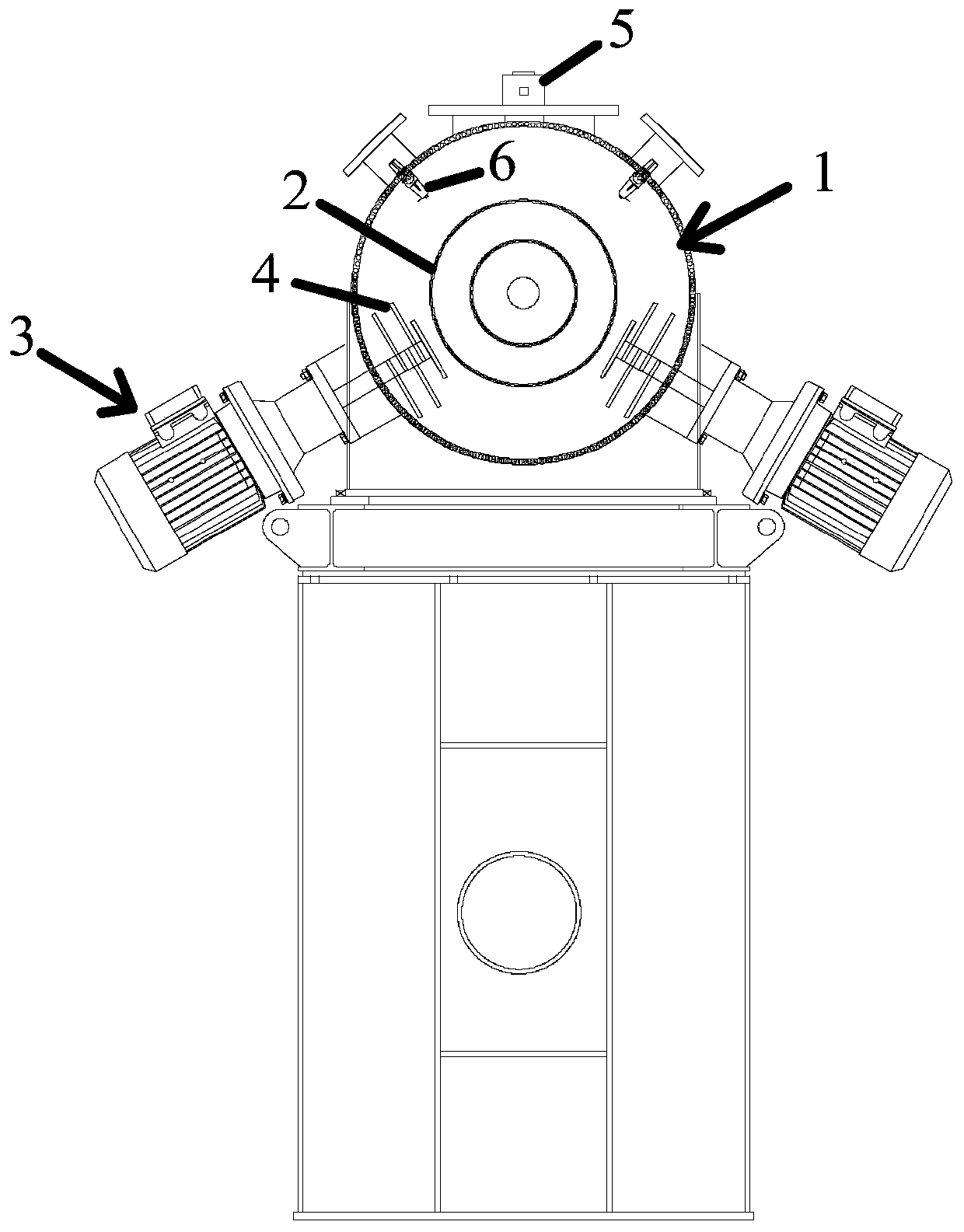

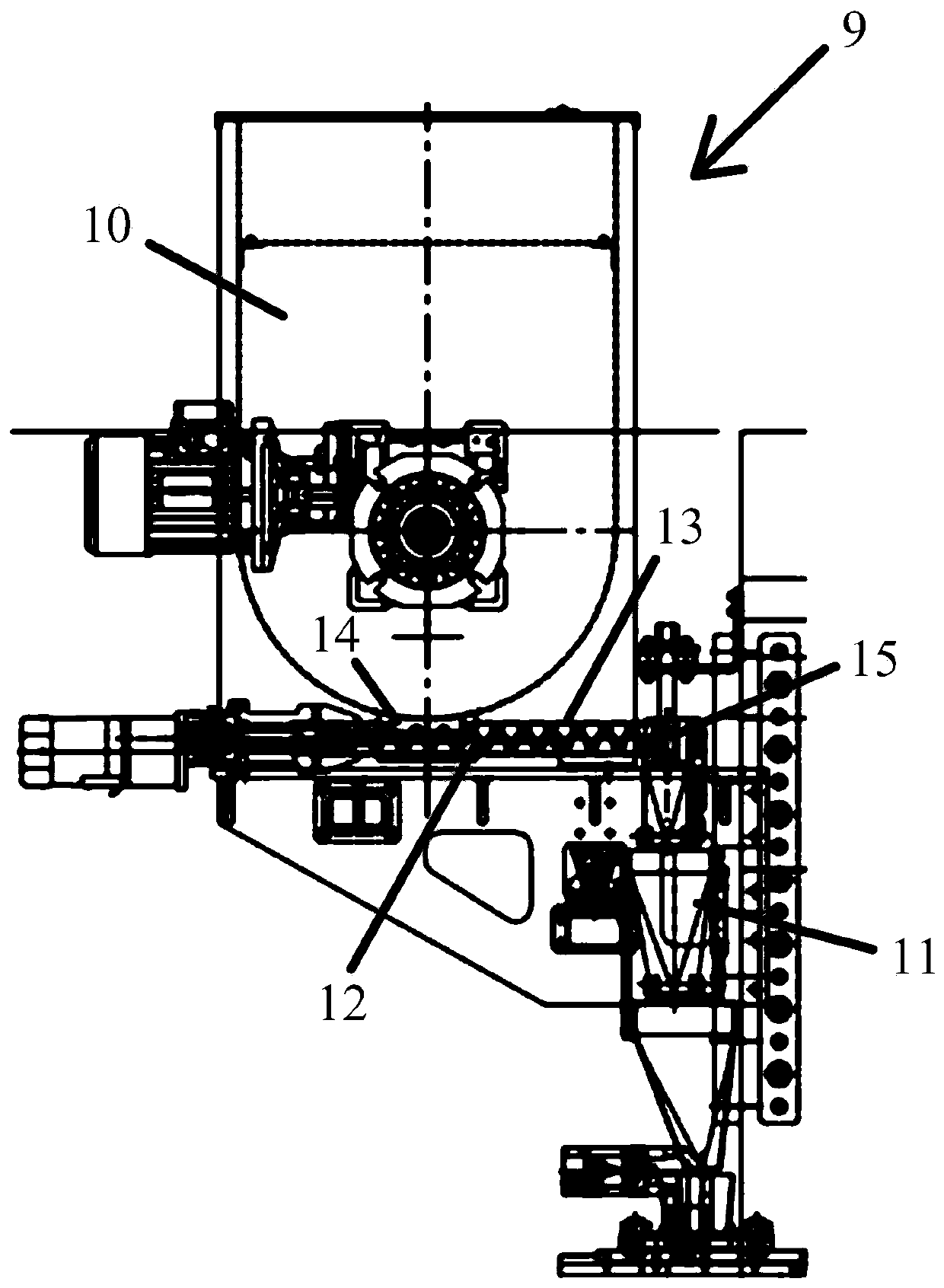

Image

Examples

preparation example Construction

[0049] The invention provides a method for preparing a friction material, which comprises the steps of batching, mixing, pressing and sintering the raw materials of the friction material in sequence, and the sintering step includes the following steps:

[0050] 1) In an atmosphere of hydrogen and / or nitrogen, heat the friction material compact at 950-1050°C and 2-4MPa for 15-30min once;

[0051] 2) After the first heat preservation is completed, the temperature of the friction material compact is lowered to 750-850°C at 2-4MPa, and a second heat preservation is carried out at 2-4MPa, 750-850°C for 15-30min;

[0052] 3) After the second heat preservation is completed, the temperature of the friction material compact is lowered to 550-650°C at 2-4MPa, and three heat preservations are carried out at 2-4MPa, 550-650°C for 15-30min;

[0053] 4) After three times of heat preservation, the pressure is released, and the friction material compact is cooled to room temperature to obtain...

Embodiment 1

[0092] This embodiment provides a friction material, which includes the following raw materials: 55 kg of copper powder, 28 kg of iron powder, 6 kg of ferrochrome powder, 6 kg of graphite, 2 kg of silicon dioxide, 1.5 kg of molybdenum disulfide, 1 kg of cast iron powder, zirconium corundum 2kg, the mass content of zirconium dioxide in the zirconium corundum is 8%.

[0093] The preparation method of the friction material comprises the following steps:

[0094] (1) batching: take described raw material respectively by above-mentioned proportioning;

[0095] (2) Mixing: mixing the weighed raw materials to obtain the friction material mixture;

[0096] (3) Pressing: pressing the friction material mixture into a compact to obtain a friction material compact, the pressing pressure is 6 MPa, and the pressing time is 5 s;

[0097] (4) sintering: the sintering step comprises the following steps:

[0098] 1) Under the atmosphere of hydrogen and nitrogen, heat the friction material co...

Embodiment 2

[0103] This embodiment provides a friction material, which includes the following raw materials: 60 kg of copper powder, 22 kg of iron powder, 8 kg of ferrochrome powder, 4 kg of graphite, 4 kg of silicon dioxide, 0.5 kg of molybdenum disulfide, 2 kg of cast iron powder, zirconium corundum 1 kg, the mass content of zirconium dioxide in the zirconium corundum is 12%.

[0104] The preparation method of the friction material comprises the following steps:

[0105] (1) batching: take described raw material respectively by above-mentioned proportioning;

[0106] (2) Mixing: mixing the weighed raw materials to obtain the friction material mixture;

[0107] (3) Pressing: pressing the friction material mixture into a compact to obtain a friction material compact, the pressing pressure is 15MPa, and the pressing time is 3s;

[0108] (4) sintering: the sintering step comprises the following steps:

[0109] 1) In an atmosphere of hydrogen and nitrogen, heat the friction material compa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com