Grinding device capable of simultaneously processing plate and pipe fittings

A technology for simultaneous processing and plate parts, which is applied in the direction of grinding machines, grinding racks, grinding bed, etc., can solve the problems of inability to process pipe parts, cannot satisfy simultaneous processing, and cannot be well adapted to adjust, so as to achieve convenient use, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

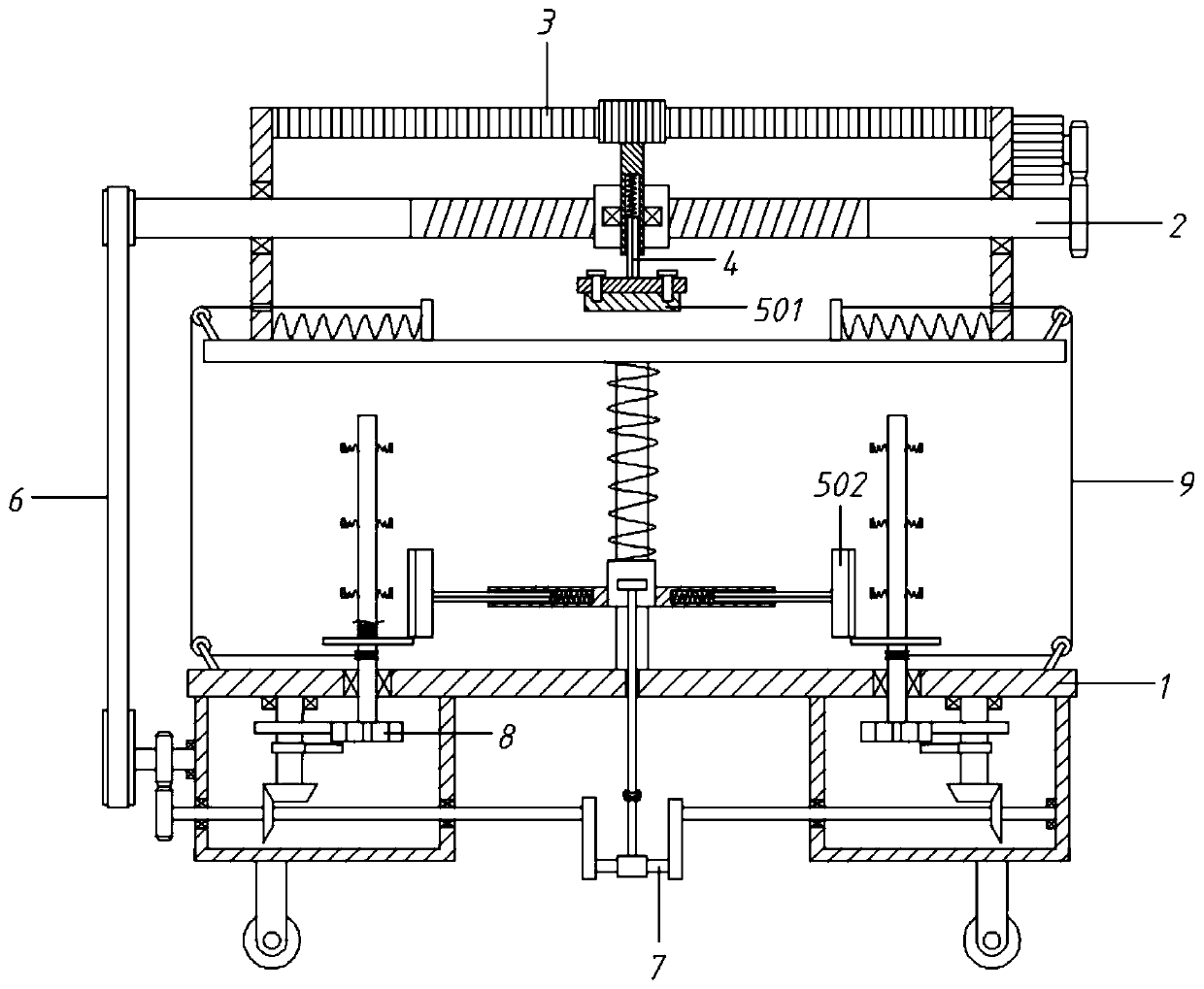

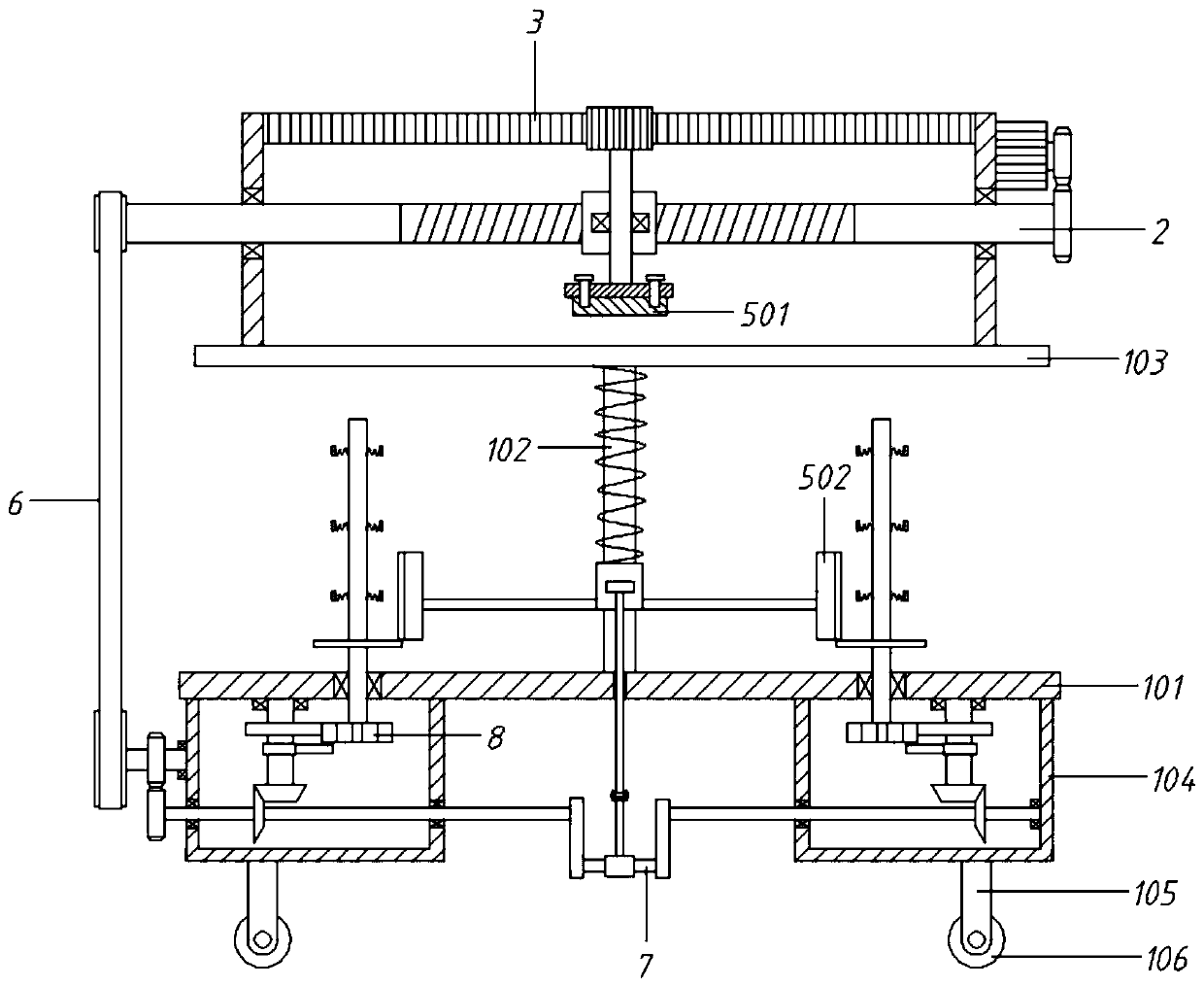

[0069] A grinding device capable of simultaneously processing plates and pipes, comprising a frame 1, a plate processing assembly, a transmission assembly 6, and a pipe processing assembly;

[0070] The frame 1 includes a base 101, a slide bar 102 and a top plate 103, the middle part of the base 101 and the middle part of the top plate 103 are connected by a slide bar 102; the left and right ends of the bottom surface of the base 101 are provided with a transmission box 104, and the bottom of the transmission box 104 is connected with a wheel 106 through a foot 105;

[0071] The top plate 103 is provided with a plate processing assembly, including a driving assembly 2, a rack assembly 3 and a type of grinding assembly 501, the driving assembly 2 is equipped with a rack assembly 3, and a type of grinding assembly 501 is provided at the bottom of the rack assembly 3;

[0072] The pipe fitting processing assembly is arranged under the base 101, including the rotating pipe assembly...

Embodiment 2

[0074] A grinding device capable of simultaneously processing plates and pipes, comprising a frame 1, a plate processing assembly, a transmission assembly 6, and a pipe processing assembly;

[0075] The frame 1 includes a base 101, a slide bar 102 and a top plate 103, the middle part of the base 101 and the middle part of the top plate 103 are connected by a slide bar 102; the left and right ends of the bottom surface of the base 101 are provided with a transmission box 104, and the bottom of the transmission box 104 is connected with a wheel 106 through a foot 105;

[0076] The top plate 103 is provided with a plate processing assembly, including a driving assembly 2, a rack assembly 3 and a type of grinding assembly 501, the driving assembly 2 is equipped with a rack assembly 3, and a type of grinding assembly 501 is provided at the bottom of the rack assembly 3;

[0077] The pipe fitting processing assembly is arranged under the base 101, including the rotating pipe assembly...

Embodiment 3

[0098] On the basis of embodiment 2,

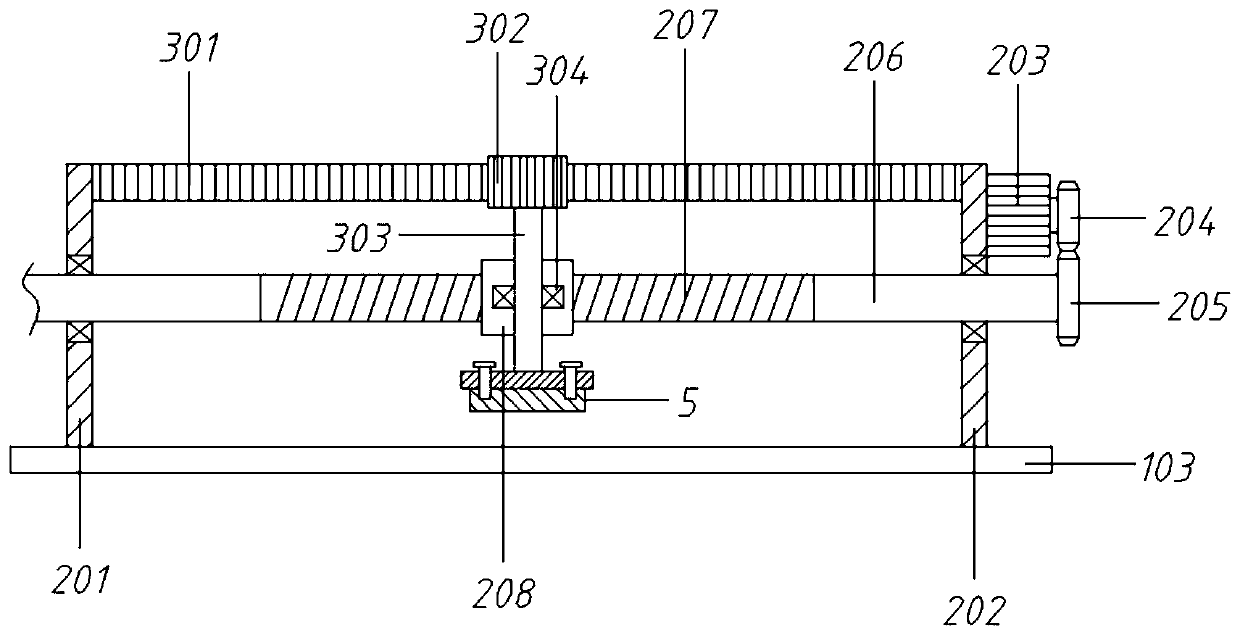

[0099] Considering that the plates have different thicknesses and the pipes have different outer diameters, the driven shaft 303 and the connecting rod are designed to have the same structure, both of which are telescopic parts 4, including the outer rod 401, the slot 402, the insertion rod 403 and the first spring 404;

[0100] The outer rod 401 is processed with a slot 402, and the slot 402 is plugged with an insertion rod 403; the outer end of the insertion rod 403 is connected to the mounting plate 5011, and the inner end is connected to a No. 1 spring 404 at the bottom of the slot 402; the cross section of the slot 402 is Irregular, corresponding to the cross-sectional shape of the slot 402;

[0101] The outer rod 401 of the driven shaft 303 is rotationally connected with the bearing seat 304, and the top end is connected with the third gear 302; the inner end of the outer rod 401 of the connecting rod is connected with the sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com