Fluorinated silicon-aluminum molecular sieve as well as preparation method and application thereof

A silica-alumina molecular sieve and molecular sieve technology, applied in the direction of molecular sieve catalysts, preparation of heterocyclic compounds, chemical instruments and methods, etc., to achieve the effects of strong stability, convenient operation, and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

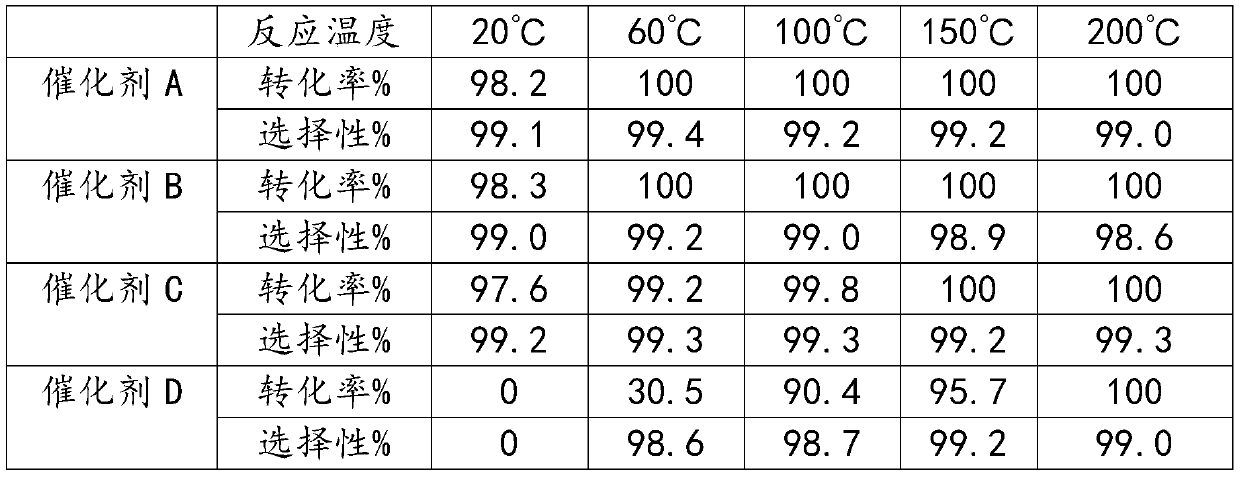

Embodiment 1

[0016] Example 1: Dry ZSM-5 molecular sieve (silicon-aluminum ratio of 10) in an oven at 120°C for 4 hours, take 10g and put it into a tube furnace, feed N2 to raise the temperature to 350°C, and change to CHClF 2 (R22) gas, the flow rate is 30ml / min, fluoride for 4 hours, change the temperature to room temperature with N2. Tablets take 20-40 mesh, which is Catalyst A.

Embodiment 2

[0017] Example 2: The specific steps are the same as those in Example 1, except that the silicon-aluminum ratio of ZSM-5 molecular sieve is 50. This is Catalyst B.

Embodiment 3

[0018] Embodiment three: the specific steps are the same as the preparation steps in embodiment one, except that the molecular sieve selected is Y type. This is Catalyst C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com