Resin coupled denitrification nitrogen removal method

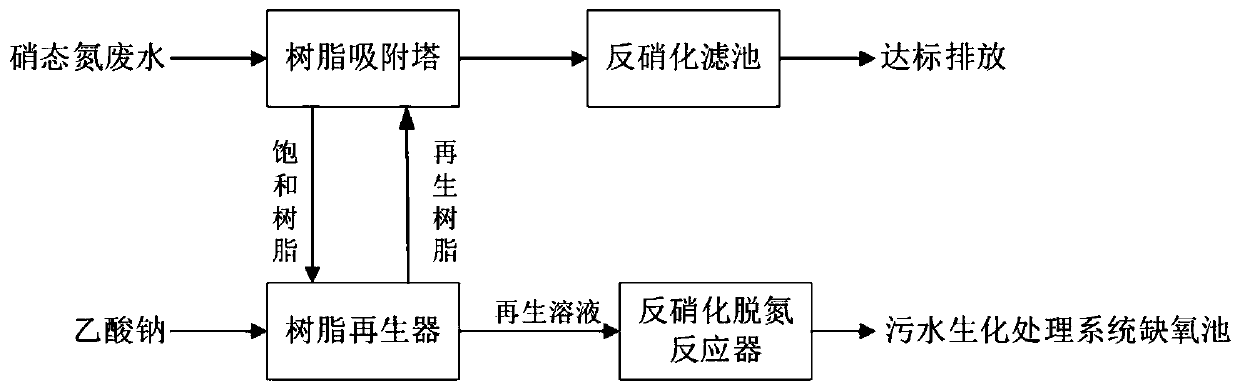

A denitrification and resin technology, applied in chemical instruments and methods, special treatment targets, water/sludge/sewage treatment, etc., can solve the problem of increasing front-end total nitrogen load and carbon source consumption, without considering the regeneration of sodium chloride Waste liquid treatment does not take into account the decline in exchange efficiency and other issues, so as to improve the stability and treatment effect, avoid the concentration of organic matter in the effluent exceeding the standard, and ensure the denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The wastewater in this example comes from the wastewater after the aerobic pool (MBR) process of the urban domestic sewage treatment plant. The steps are:

[0036]A. The process of removing nitrate nitrogen by ion exchange resin: firstly, the waste water flows through the domestic 201×7 (717) strongly basic anion exchange resin at a flow rate of 6BV / h, and the average concentration of nitrate nitrogen in the effluent of the resin adsorption tower is 2mg / h L;

[0037] B. The regeneration process of ion exchange resin: output the saturated resin in the ion exchange resin adsorption tower to the resin regenerator, the temperature of the regenerator is controlled at 25°C to 35°C, and the resin is regenerated with 2% sodium acetate solution, single batch The volume of sodium acetate solution required for resin regeneration is twice the volume of the resin. The regenerated resin is returned to the ion exchange resin adsorption tower, and the regeneration solution continues ...

Embodiment 2

[0043] The waste water in this embodiment comes from the waste water after the aerobic pool process of the industrial sewage treatment plant, the concentration of nitrate nitrogen is 70-80mg / L, and the water temperature is 10°C-15°C. The steps of the waste water treatment are:

[0044] A. The process of ion exchange resin to remove nitrate nitrogen: firstly, the waste water flows through the strong basic anion exchange resin of domestic Pu-rolite A520E (produced by Piao Lai Te (China) Co., Ltd., Nanjing, China) at a flow rate of 1BV / h, and the resin adsorption tower The average concentration of nitrate nitrogen in the effluent is 10mg / L;

[0045] B. The regeneration process of ion exchange resin: output the saturated resin in the ion exchange resin adsorption tower to the resin regenerator, the temperature of the regenerator is controlled at 25°C to 35°C, and the resin is regenerated with 8% sodium acetate solution, single batch The volume of sodium acetate solution required f...

Embodiment 3

[0049] The waste water of this embodiment comes from the waste water after the aerobic pool process of the industrial sewage treatment plant, the concentration of nitrate nitrogen is 30-50mg / L, and the water temperature is 10°C-15°C. The steps of the waste water treatment are:

[0050] A. The process of removing nitrate nitrogen by ion exchange resin: firstly, the waste water flows through the strong basic anion exchange resin of domestic Pu-rolite A520E (produced by Piao Laite (China) Co., Ltd., Nanjing, China) at a flow rate of 4BV / h, and the resin adsorption tower The average concentration of nitrate nitrogen in the effluent is 5mg / L;

[0051] B. The regeneration process of ion exchange resin: output the saturated resin in the ion exchange resin adsorption tower to the resin regenerator, the temperature of the regenerator is controlled at 25°C to 35°C, and the resin is regenerated with 5% sodium acetate solution, single batch The volume of sodium acetate solution required f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com