High-heat-resistance bismaleimide resin as well as preparation method and application thereof

A technology of maleimide resin and bismaleimide, which is applied in the direction of organic chemistry, can solve the problems of heat resistance decline, and achieve the effects of improving brittleness, easy operation, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

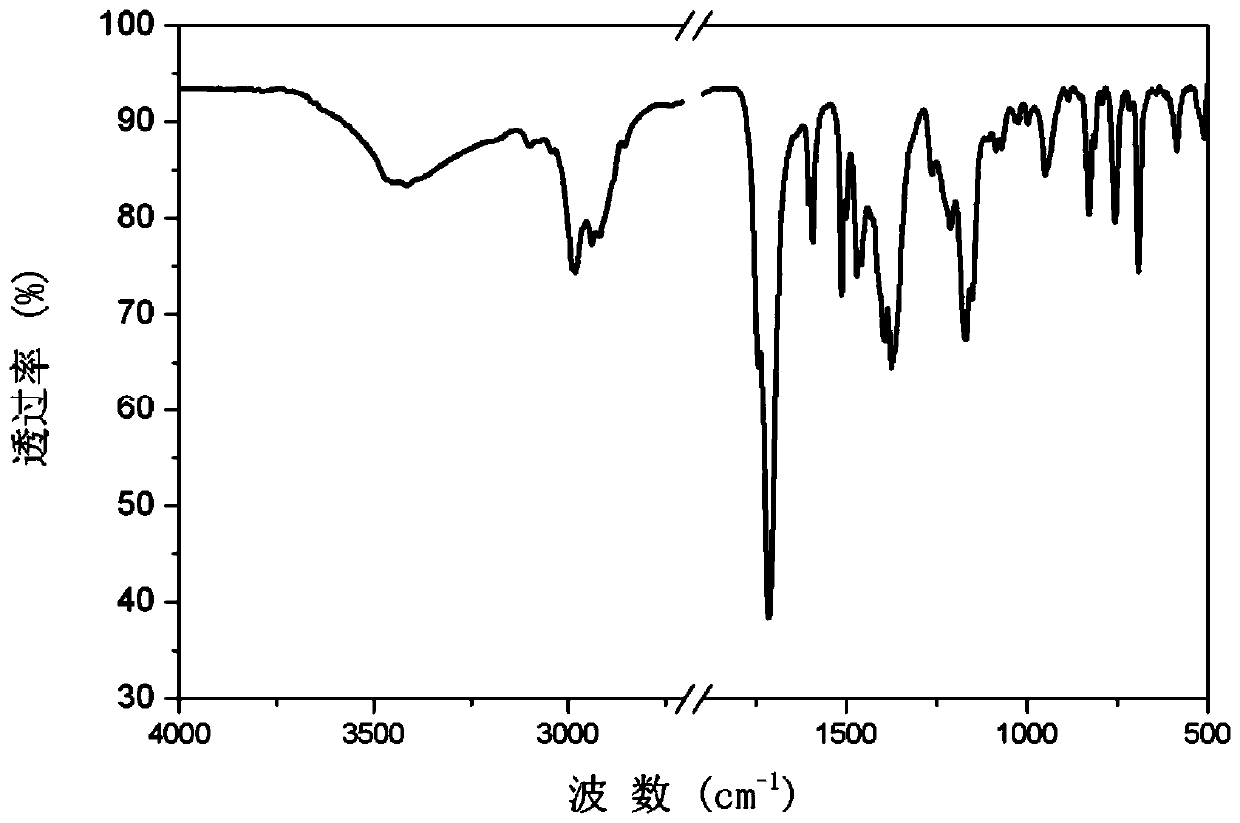

Image

Examples

Embodiment 1

[0021] The preparation of high heat-resistant bismaleimide resin, implementation steps are:

[0022] Add 0.1mol hydroxyaromatic amine and 100ml solvent into reactor A equipped with stirrer, thermometer, reflux condenser and constant pressure dropping funnel, stir and dissolve; put 0.22~0.3mol maleic anhydride in vessel B Dissolve in 100-150ml of solvent, and configure it as a maleic anhydride solution; drop the dissolved maleic anhydride solution into the reactor through a constant-pressure dropping funnel at a rate of 1-2ml / min in a water bath In A, continue to stir for 2-3 hours after the dropwise addition; then add 0.25-0.38mol acetic anhydride, 0.0001-0.001mol catalyst, heat up to 60°C-65°C, react for 3-4h, cool down, use a large amount of tap water to precipitate, The high heat-resistant bismaleimide resins of Examples 1-1 to 1-4 were obtained by filtration, washing and recrystallization.

[0023] Wherein the hydroxy aromatic amine is 3,3'-dihydroxy-4,4'-diaminodiphenylm...

Embodiment 2

[0028] The preparation of high heat-resistant laminates, the implementation steps are:

[0029] (1) 75-134 parts by mass of high heat-resistant bismaleimide resin, 100 parts by mass of epoxy resin, 0-20 parts by mass of curing agent, 0.3-0.8 parts by mass of curing accelerator, 18-94 parts by mass of inorganic The filler is uniformly mixed with an appropriate amount of solvent to make a resin composition with a solid content of 60% to 70%. Use 1080E glass fiber cloth to control the resin content to 68%, and bake it at 130°C to 170°C for 1 to 10 minutes to make a prepreg;

[0030] (2) Use 10 prepregs and attach copper foil on both sides, place them in a vacuum hot press, increase the temperature from room temperature to 170°C at a rate of 3°C / min, and press from 0.5MPa to 0.1MPa / 1min Increase the speed to 4MPa, evacuate to within 50torr, keep pressing for 2h, then raise the temperature to 200°C for 2h, then heat up to 250°C for 2h, release the pressure and cool naturally to 150...

Embodiment 3

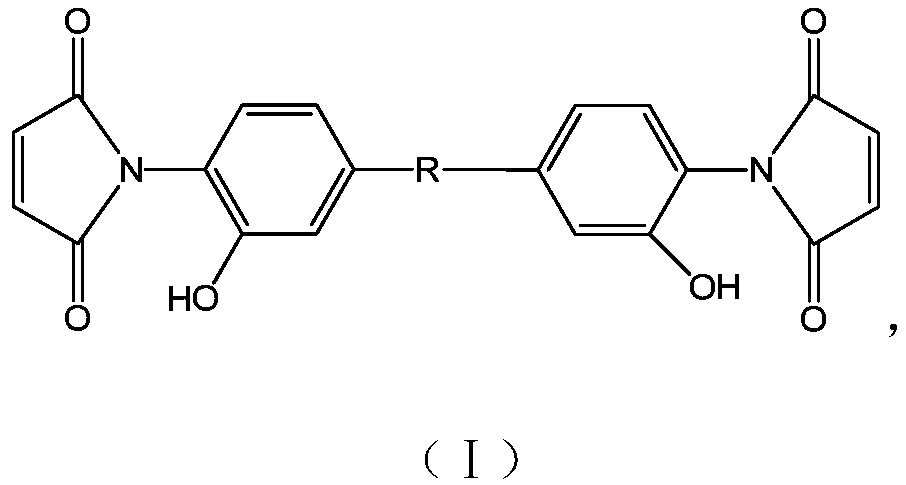

[0084] A kind of high heat-resistant bismaleimide resin, this high heat-resistant bismaleimide resin has the general chemical structure formula shown in (I):

[0085]

[0086] In formula (I): R is-SO 2 -, -CH 2 -, -O-, -C(CH 3 ) 2 - Any one of the above, the high heat-resistant bismaleimide resin is a light yellow powder, with a melting range of 162°C to 253°C and an acid value of 0.3 to 0.7mgKOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com