Rapid epoxy curing agent at room temperature and its application in the preparation of epoxy dry-hanging adhesive

A technology of epoxy curing agent and curing agent, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., and can solve the problems of high rigidity, high price, and insufficient strength

- Summary

- Abstract

- Description

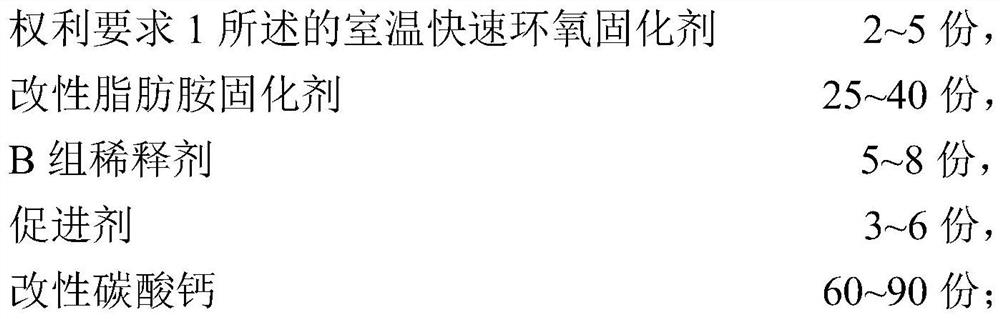

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

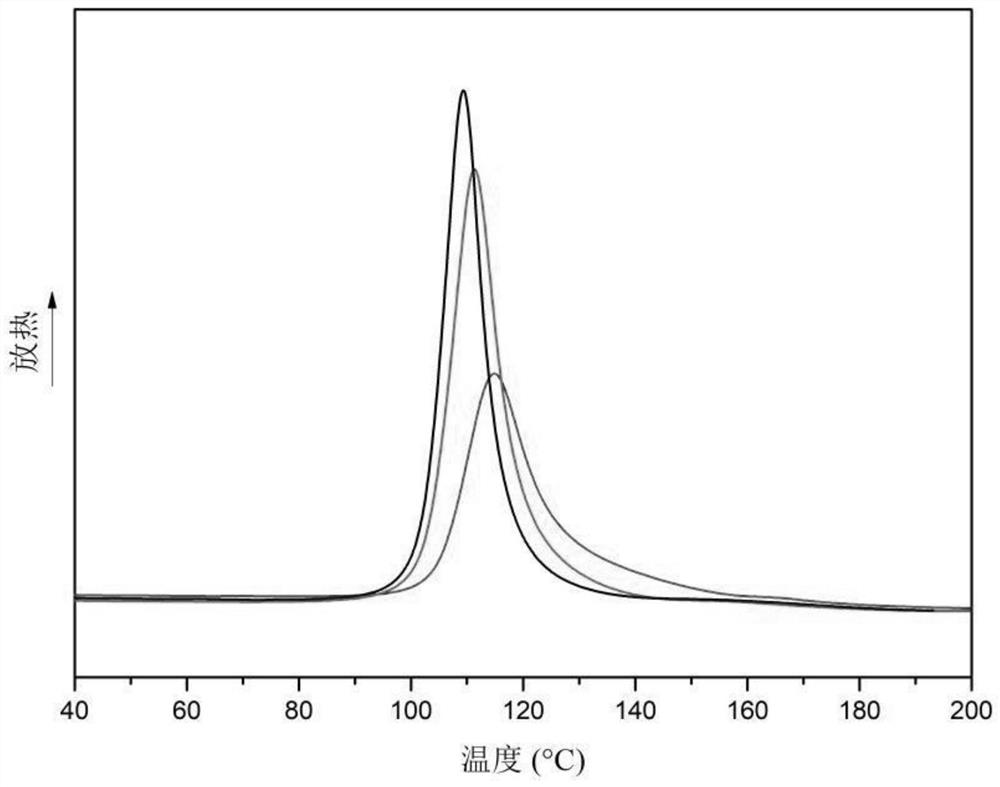

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with specific embodiments, so that those skilled in the art can understand.

[0045] In the room temperature rapid epoxy curing agent of the present invention, the raw materials of the curing agent include 80-120 parts of pentaerythritol, 250-350 parts of thioglycolic acid, 50-140 parts of epoxy resin, 0.10-0.20 Parts of diisocyanate and 5.5 to 44 parts of imidazole.

[0046] The raw materials used in the present invention are all purchased on the market, and bisphenol A epoxy resin is purchased from South Asia Epoxy Resin (Kunshan) Co., Ltd., and the model is 128,

[0047] According to the raw material components of the above room temperature fast epoxy curing agent combined with the actual situation, the formula of the room temperature fast epoxy curing agent is established:

[0048] Table 1 The formula of rapid epoxy curing agent at room temperature

[0049] pentaerythritol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com