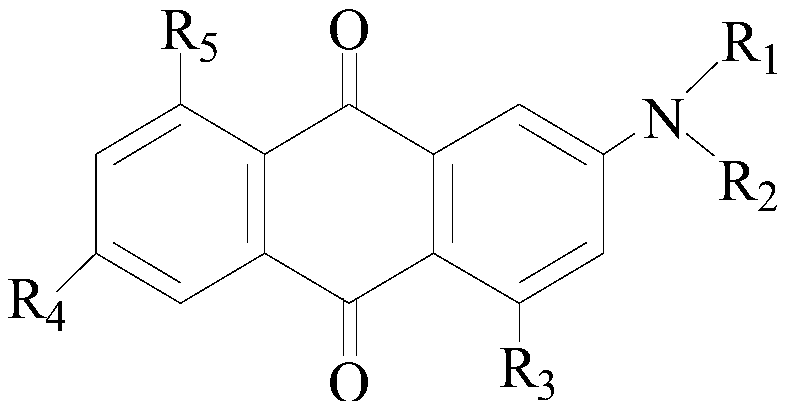

Anthraquinone structure carboxylic acid type dye for alginate fiber dyeing and preparation method and dyeing process thereof

A technology of seaweed fiber and structural carboxylic acid is applied in the field of anthraquinone structure carboxylic acid type dye for seaweed fiber dyeing and its preparation method and dyeing process, which can solve the problem of weak bonding between dye and fiber, hindering the development of seaweed fiber and dyeing process. Cumbersome and other problems, to achieve the effect of improving dyeing depth and dyeing rate, improving water solubility and permeability, and simple dyeing liquid configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Synthesis of anthraquinone dye intermediates containing ester groups

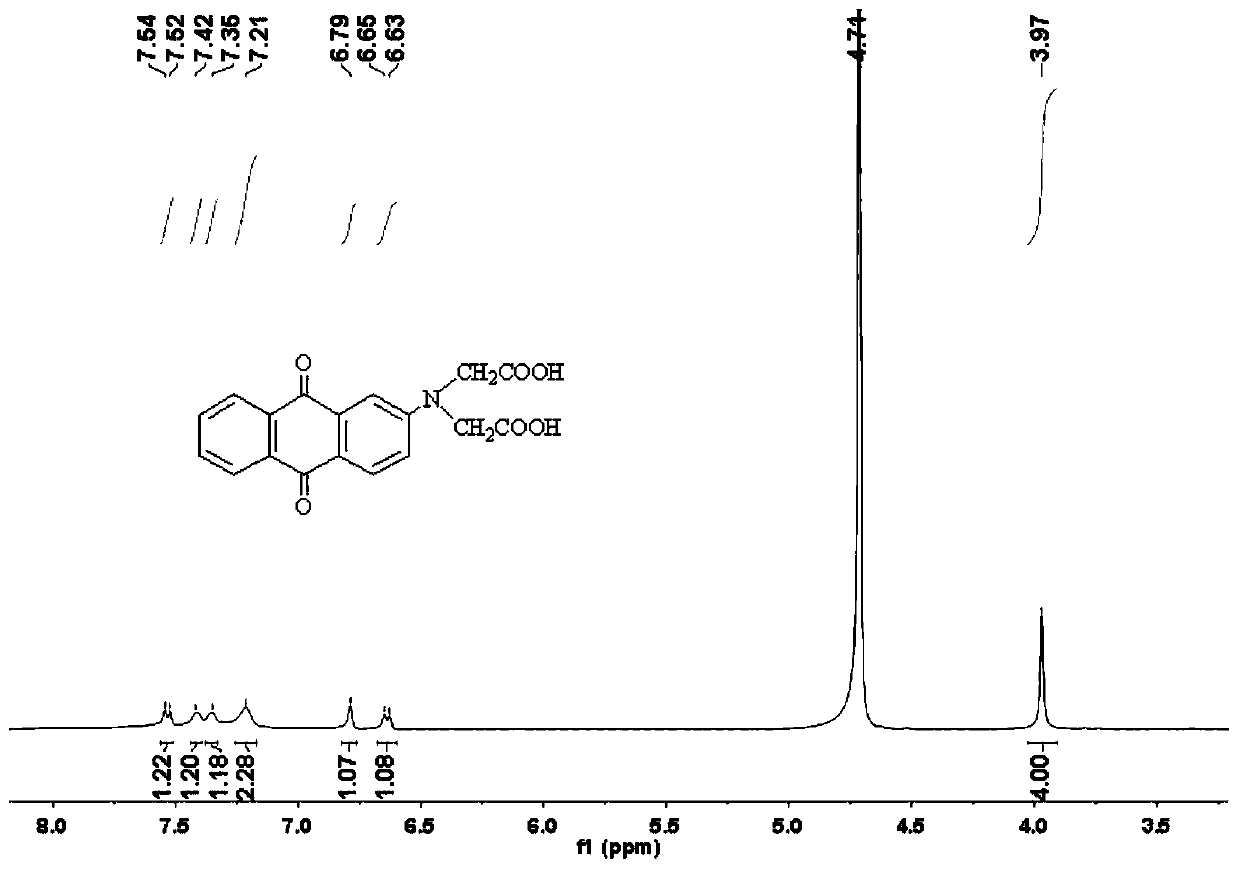

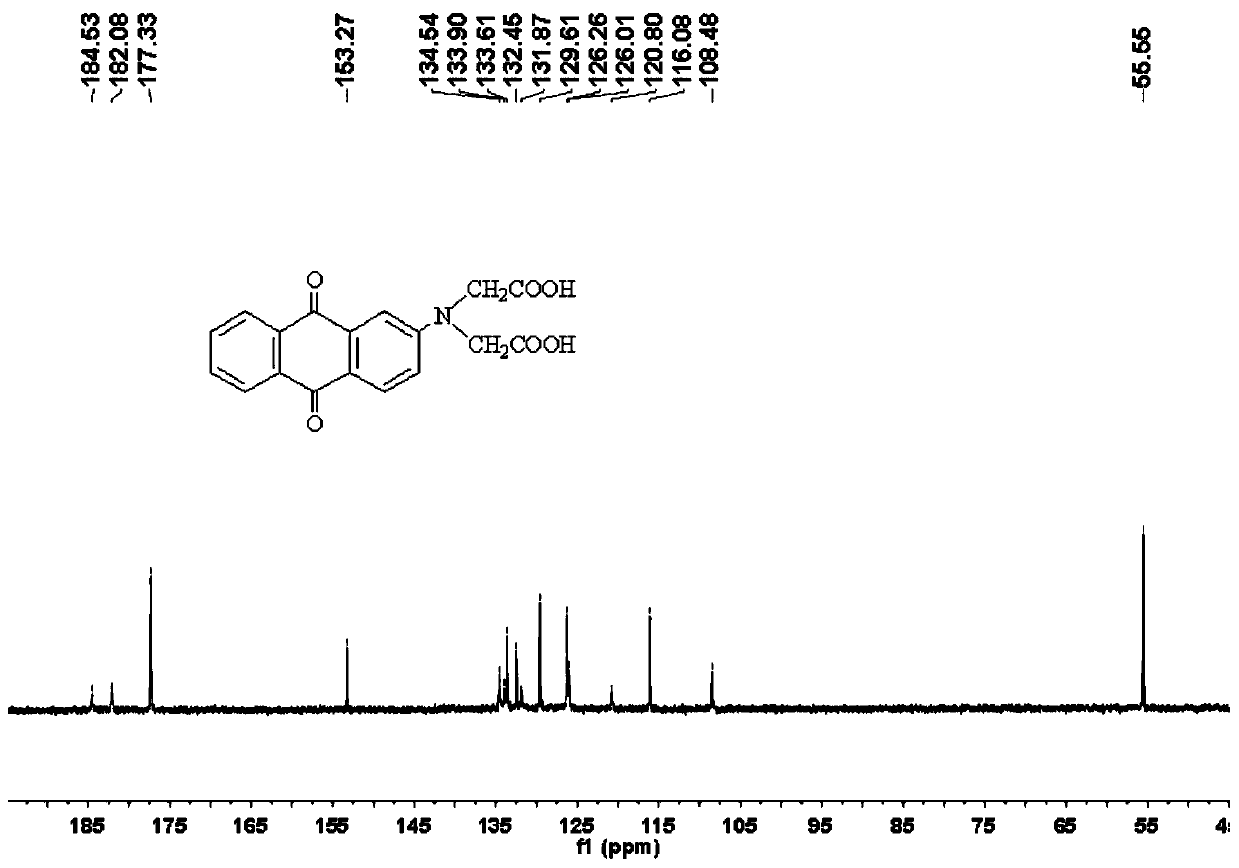

[0051] Weigh respectively 2.23g (10mmol) of 2-aminoanthraquinone, 11.1mL (16.7g, 100mmol) of ethyl bromoacetate, 0.10g (0.6mmol) of potassium iodide and 0.142g (1.1mmol) of N,N-diisopropylethylamine ) into a three-neck flask, add 80 mL of acetonitrile, heat and stir, and reflux for 24 hours to obtain a dark brown solution. Acetonitrile is removed by rotary evaporation, then distilled water is added, extracted with dichloromethane several times, the organic phase is taken, and the product is collected by rotary evaporation to obtain Anthraquinone dye intermediates.

[0052] The reaction equation is as follows:

[0053]

[0054] (2) Synthesis of anthraquinone structural carboxylic acid dyes for seaweed fiber dyeing

[0055] Add 80 mL of ethanol and 2.4 g (60 mmol) of NaOH to the ester-containing anthraquinone dye intermediate collected in step (1), and reflux for 18 hours. After the reflux, th...

Embodiment 2

[0065] (1) Synthesis of anthraquinone dye intermediates containing ester groups

[0066] Weigh 2.51g (10mmol) of 2-amino-4,8-dimethylanthraquinone, 8.87mL (13.36g, 80mmol) of ethyl bromoacetate, 0.133g (0.8mmol) of potassium iodide and N,N-diisopropyl Add 0.168g (1.3mmol) of ethyl ethylamine to a three-necked flask, add 60mL of acetonitrile, heat and stir, and reflux for 18 hours to obtain a dark brown solution. Rotate off the acetonitrile, then add distilled water, extract with dichloromethane several times, and take the organic phase , and the product was collected by rotary evaporation to obtain an anthraquinone dye intermediate containing an ester group.

[0067] The reaction equation is as follows:

[0068]

[0069] (2) Synthesis of anthraquinone structural carboxylic acid dyes for seaweed fiber dyeing

[0070] Add 60mL of ethanol and 2.0g (50mmol) of NaOH to the intermediate of anthraquinone dyes containing ester groups collected in step (1), and reflux for 15h. Aft...

Embodiment 3

[0078] (1) Synthesis of anthraquinone dye intermediates containing ester groups

[0079] Weigh 2.23g (10mmol) of 2-aminoanthraquinone, 12.8mL (18.1g, 100mmol) of ethyl 3-bromopropionate, 0.166g (1mmol) of potassium iodide and 0.194g of N,N-diisopropylethylamine ( 1.5mmol) into a three-necked flask, add 100mL of acetonitrile, heat and stir, and reflux for 20h to obtain a dark brown solution. Acetonitrile is removed by rotary evaporation, then distilled water is added, extracted with dichloromethane several times, the organic phase is taken, and the product is collected by rotary evaporation to obtain Anthraquinone dye intermediates containing ester groups.

[0080] The reaction equation is as follows:

[0081]

[0082] (2) Synthesis of anthraquinone structural carboxylic acid dyes for seaweed fiber dyeing

[0083] Add 100mL of ethanol and 2.8g (70mmol) of NaOH to the ester-containing anthraquinone dye intermediate collected in step (1), and reflux for 12h. After the reflux, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com