Flexible conductive fiber membrane material and preparation method thereof

A technology of flexible conductive fibers and membrane materials, applied in the manufacture of conductive/antistatic filaments, fiber treatment, electrospinning, etc., can solve the problems of single fiber size, inability to load polyaniline, and inability to further improve electrical conductivity, etc., to achieve Effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

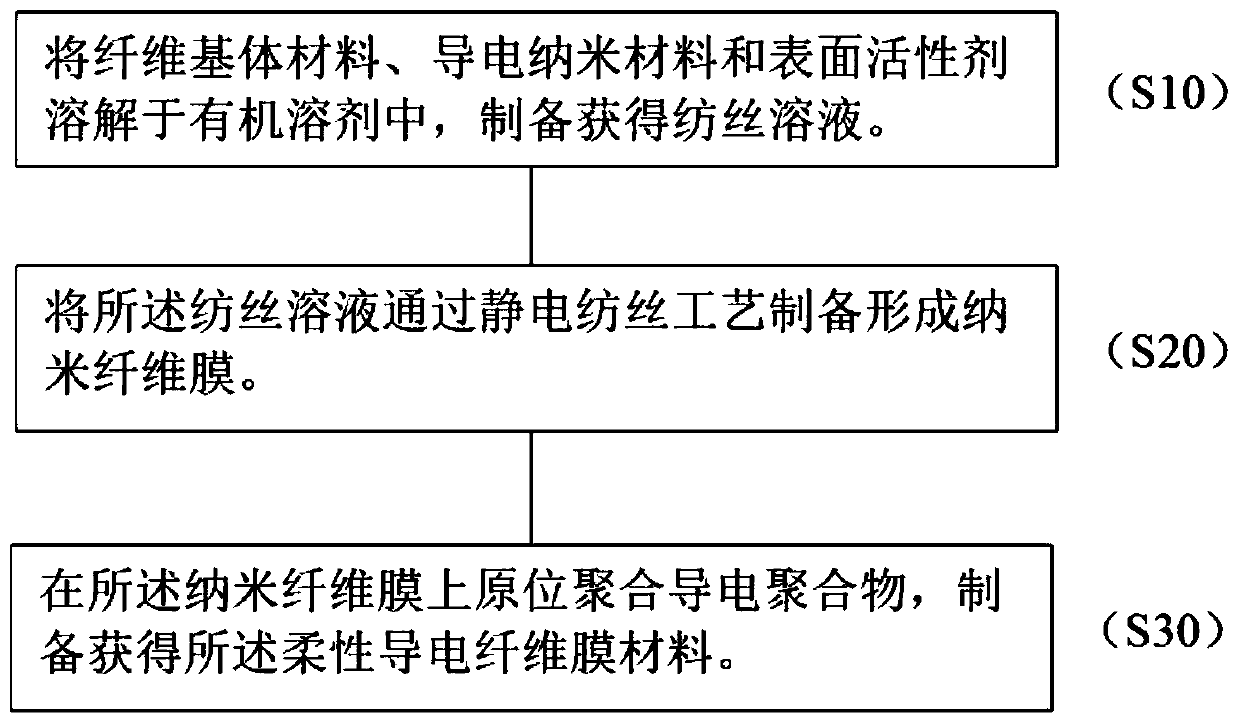

[0039] Embodiments of the present invention firstly provide a method for preparing a flexible conductive fiber membrane material, such as figure 1 As shown, the preparation method includes the following steps.

[0040] Step S10, dissolving the fiber matrix material, the conductive nanomaterial and the surfactant in an organic solvent to prepare a spinning solution.

[0041] Wherein, the mass fraction of the fiber matrix material is 5%-25%, the mass fraction of the surfactant is 0.01-0.1%, and the mass fraction of the conductive nanomaterial is 2-20%. In a preferred solution, the mass fraction of the conductive nanomaterial is 2-10%.

[0042]Wherein, the fiber matrix material is selected from any one of polyamide, polyacrylic acid, polyurethane, chitosan or silk fibroin, and the conductive nanomaterial is selected from any of carbon nanotubes, graphene or nano-metal particles. One, the surfactant is selected from sodium dodecylsulfonate, dodecyltrimethylammonium bromide, sodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com