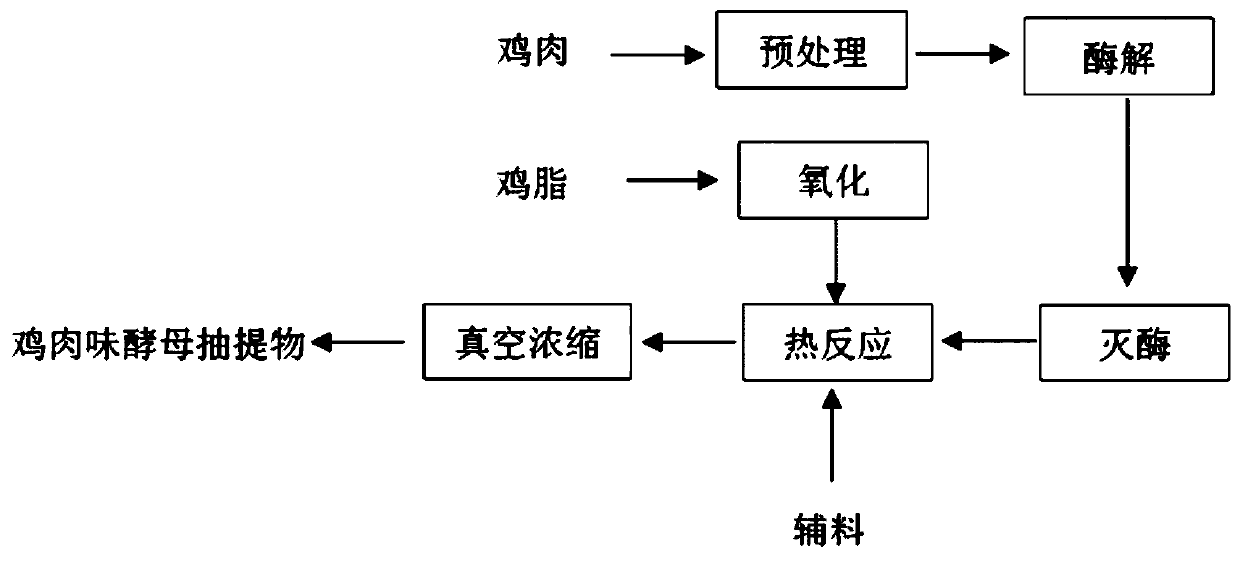

Chicken-flavor yeast extract and preparation method thereof

A yeast extract, yeast extract technology, applied in food science, food ingredients as odor modifiers, food heat treatment and other directions, can solve the problems of no production mode found, complex reaction conditions, affecting the taste of yeast extract, etc. To achieve the effect of rich and mellow chicken aroma and rich flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Chicken pretreatment: Remove the fat and connective tissue from the chicken, cut into small pieces and mix it with water at a ratio of 1:2, then crush it into a pulp with a tissue grinder, pass it through a colloid mill to homogenize it, and place it in the Heat at 85°C for 10 minutes to inactivate enzymes and cool down;

[0046] (2) Enzymolysis: carry out two-stage enzymolysis with chicken pulp, trypsin and flavor protease, the enzymolysis temperature is 50°C, and the time is 4h;

[0047] Further, the first stage is trypsin enzymolysis, the amount of trypsin added is 4‰, and the holding time is 1h; the second stage is adding flavor protease 3‰, and the holding time is 2.5h;

[0048] (3) Enzyme inactivation: heat the chicken enzymatic solution in (2) at 90°C for 10 minutes to inactivate the enzyme;

[0049] (4) Oxidation of chicken fat: Heat and melt chicken fat. When the temperature rises to 110°C, start to pass the air flow at 200L / (h·kg) and stir (450 r / min) for...

Embodiment 2

[0053] (1) Chicken pretreatment: Remove the fat and connective tissue from the chicken, cut into small pieces and mix it with water at a ratio of 1:2, then crush it into a pulp with a tissue grinder, pass it through a colloid mill to homogenize it, and place it in the Heat at 87°C for 12 minutes to inactivate enzymes and cool down;

[0054] (2) Enzymolysis: carry out two-stage enzymolysis with chicken pulp, trypsin and flavor protease, the enzymolysis temperature is 52°C, and the time is 4h;

[0055] Further, the first stage is trypsin enzymatic hydrolysis, the amount of trypsin added is 4‰, and the holding time is 1.5h; the second stage is adding flavor protease 3‰, and the holding time is 3h;

[0056] (3) Enzyme inactivation: heat the chicken enzymatic solution in (2) at 95°C for 10 minutes to inactivate the enzyme;

[0057] (4) Oxidation of chicken fat: chicken fat is heated and melted. When the temperature rises to 110 °C, the air flow rate is 210 L / (h kg) and stirred (45...

Embodiment 3

[0061] (1) Chicken pretreatment: Remove the fat and connective tissue from the chicken, cut into small pieces and mix it with water at a ratio of 1:2, then crush it into a pulp with a tissue grinder, pass it through a colloid mill to homogenize it, and place it in the Heat at 90°C for 15 minutes to inactivate enzymes and cool down;

[0062] (2) Enzymolysis: carry out two-stage enzymolysis with chicken pulp, trypsin and flavor protease, the enzymolysis temperature is 55°C, and the time is 4h;

[0063] Further, the first stage is trypsin enzymatic hydrolysis, the amount of trypsin added is 4.5‰, and the holding time is 1.5h; the second stage is adding flavor protease 3.5‰, and the holding time is 3h;

[0064] (3) Enzyme inactivation: heat the chicken enzymatic solution in (2) at 95°C for 15 minutes to inactivate the enzyme;

[0065] (4) Oxidation of chicken fat: chicken fat is heated and melted. When the temperature rises to 110°C, the air flow rate is 220L / (h·kg) and stirred (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com