Device and method for absorbing tail gas in air bromine blowing production

A technology of tail gas absorption device and tail gas absorption tower, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, to achieve good social environmental protection benefits, less equipment investment, and full absorption effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

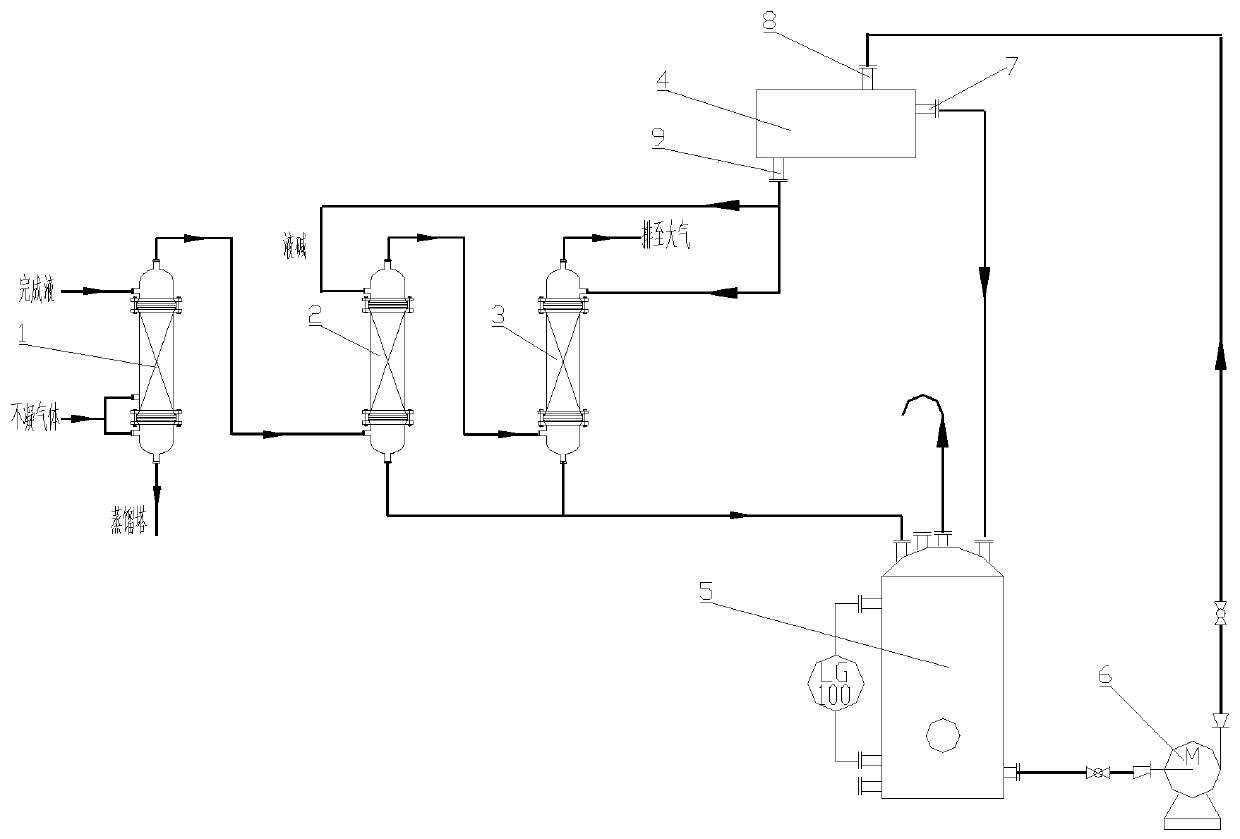

[0029] See attached figure 1 , the device of the present invention comprises a tail gas absorption tower 1, an alkali washing tower, a lye tank 5 and connected pipelines, the tail gas absorption tower 1 and the alkali washing tower are connected in series, so that tail gas is discharged from the top of the tail gas absorption tower 1 and enters from the bottom Alkali washing tower, the discharge port at the bottom of the alkali washing tower is connected with the lye tank 5, including the lye buffer tank 4, which is connected with the alkali washing tower and the lye tank 5 through pipelines, and the lye buffer tank is provided with a buffer Tank inlet 8, buffer tank outlet 9, buffer tank inlet 8 is arranged on the top of lye b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com