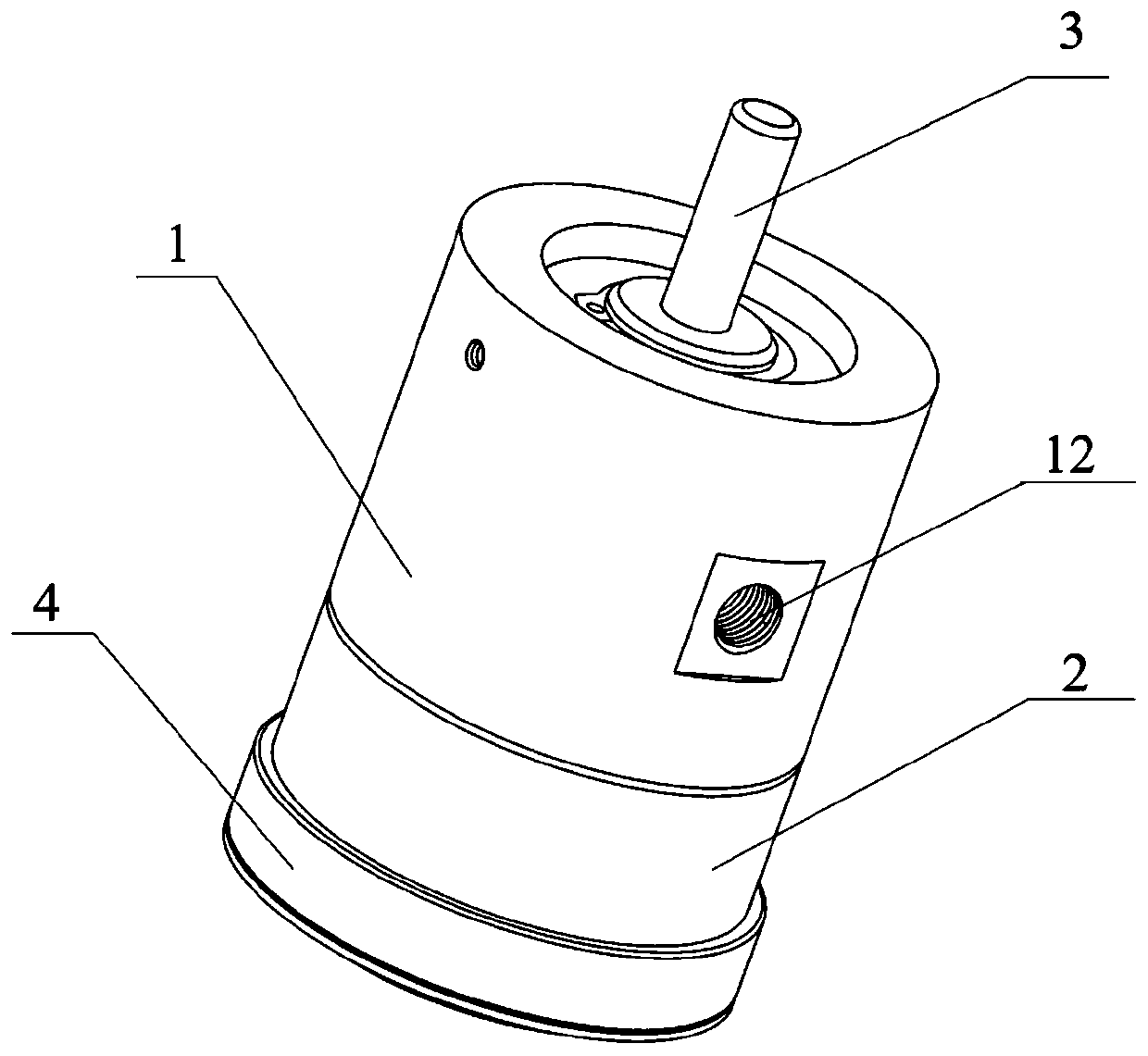

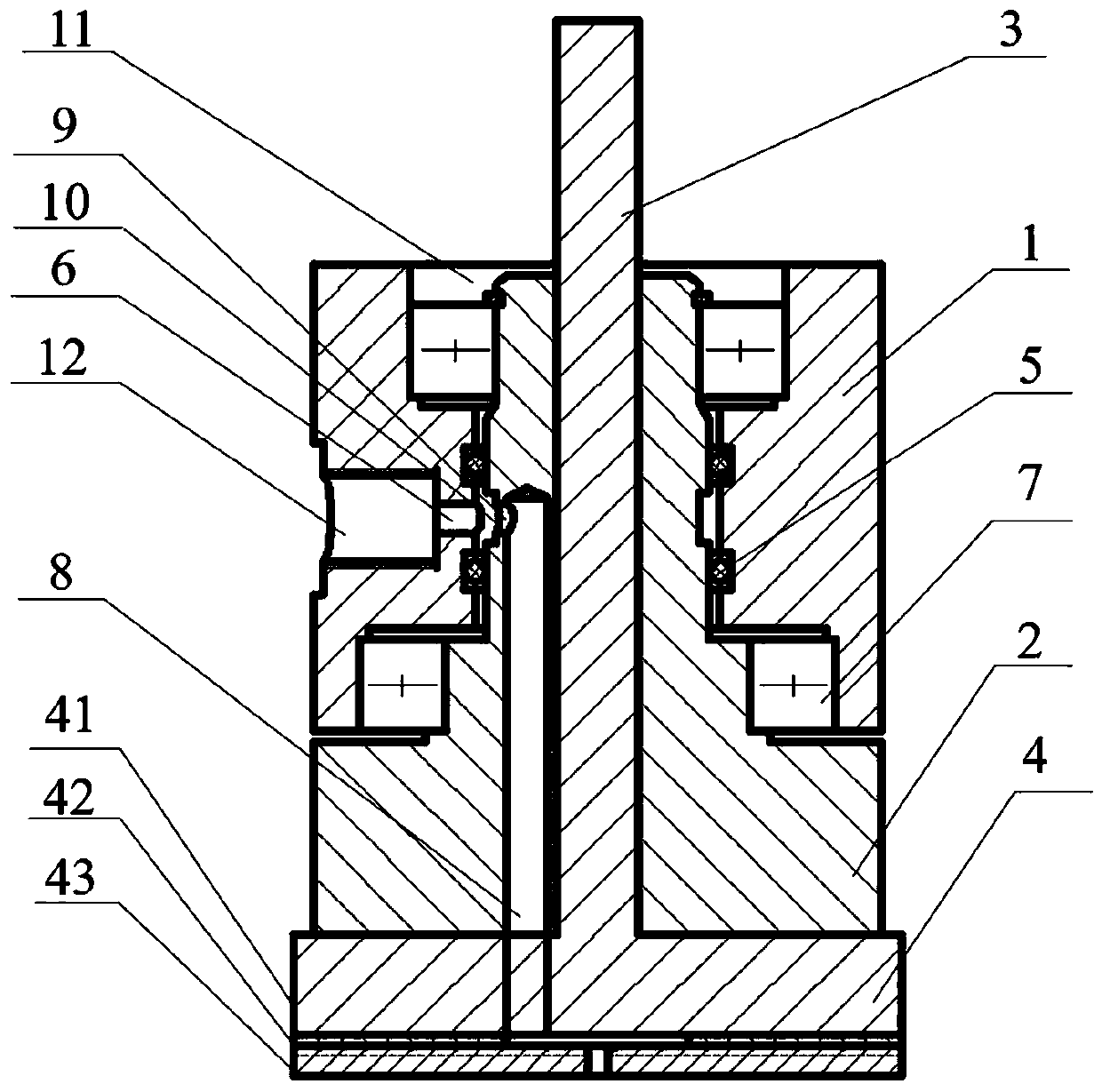

Numerical control polishing device liquid supplied through inner flow channel

A polishing device and internal flow channel technology, applied in grinding/polishing equipment, parts of grinding machine tools, metal processing equipment, etc., can solve the problem of difficult to control the surface uniformity of polished workpieces, abrasive aggregation, and excessive wear of polishing pads, etc. problems, to achieve the effect of improving polishing efficiency and polishing surface quality, stable update speed, and uniform distribution of abrasive particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

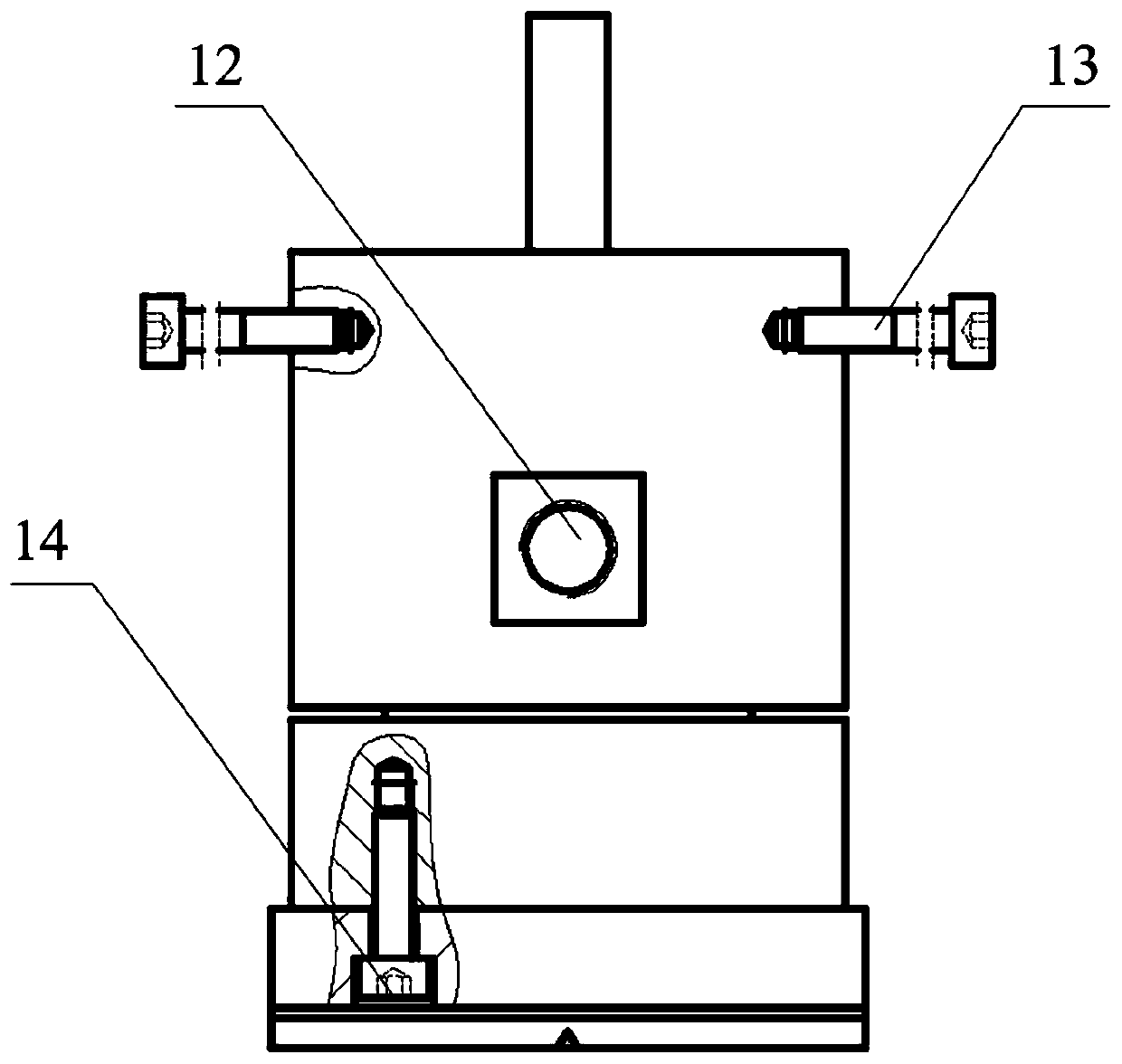

[0028] Embodiment: In order to verify the effect of the polishing tool of the present invention, the experimental device is installed according to the implementation steps, and the numerically controlled polishing device with the inner channel liquid supply provided by the present invention and the traditional peripheral liquid supply polishing device are respectively used in the same A comparative experiment of polishing high-alumina-silicon tempered glass was carried out under the process parameters. After the experiment, the wear of the polishing layer, that is, the polyurethane polishing pad under different liquid supply methods was observed under an ultra-depth-of-field microscope.

[0029] Figure 4 (a) is the surface morphology of the polyurethane polishing pad after internal liquid supply polishing for 30 minutes, Figure 4 (b) is the surface morphology of the polyurethane polishing pad after polishing with liquid supply around it for 30 minutes. from Figure 4 (a) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com