Application method of ultrasonic vibration-assisted polishing device for superhard material microstructure surface

A superhard material, ultrasonic vibration technology, applied in the field of high-efficiency and high-precision polishing of ceramic superhard linear microstructure surfaces, can solve the problem of uneven surface quality, easy damage at the sharp point of the microstructure, and low efficiency of mechanical polishing methods, etc. problems, to achieve the effect of improving surface accuracy, increasing three-body wear, and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

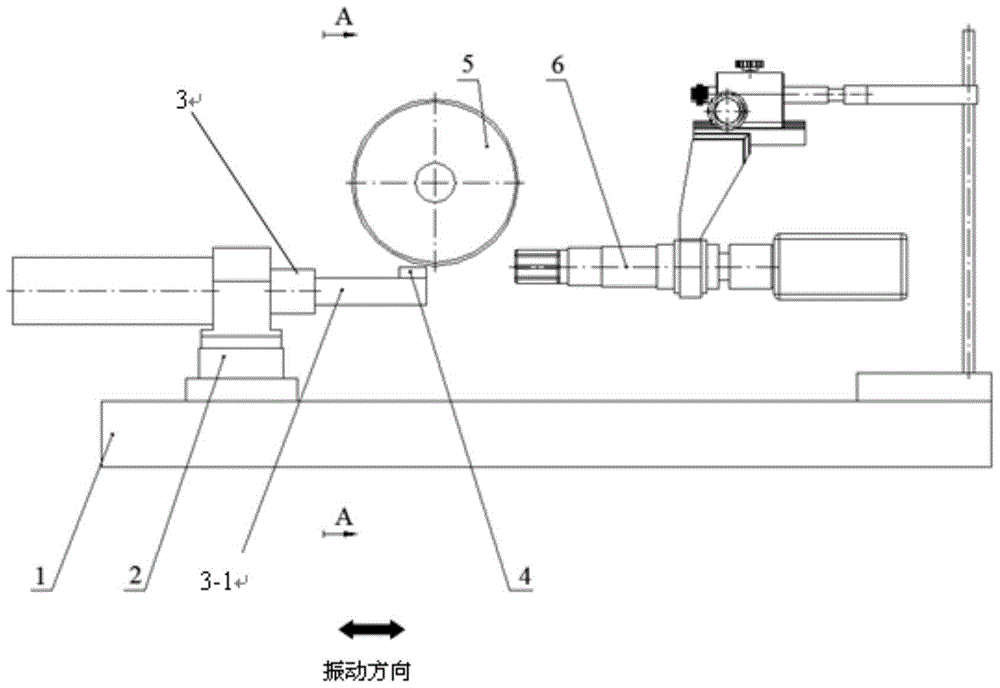

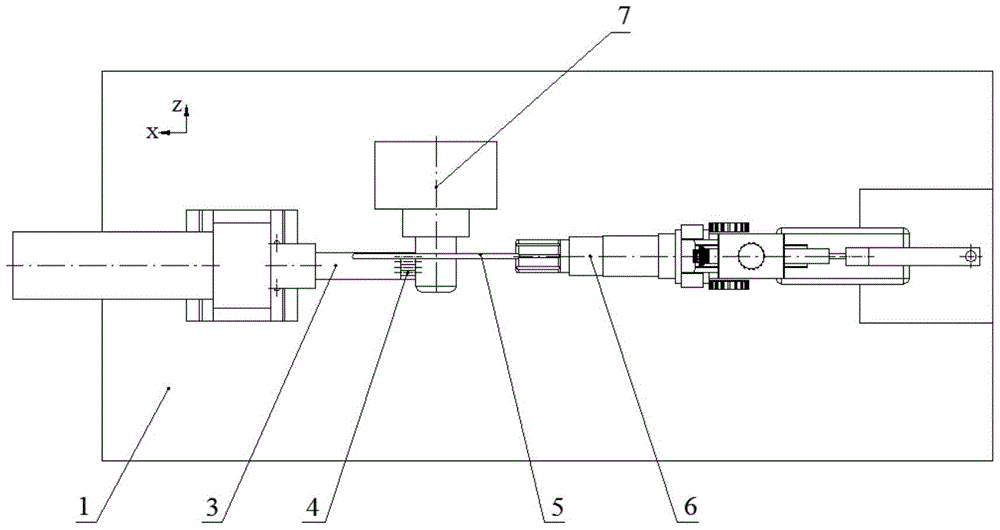

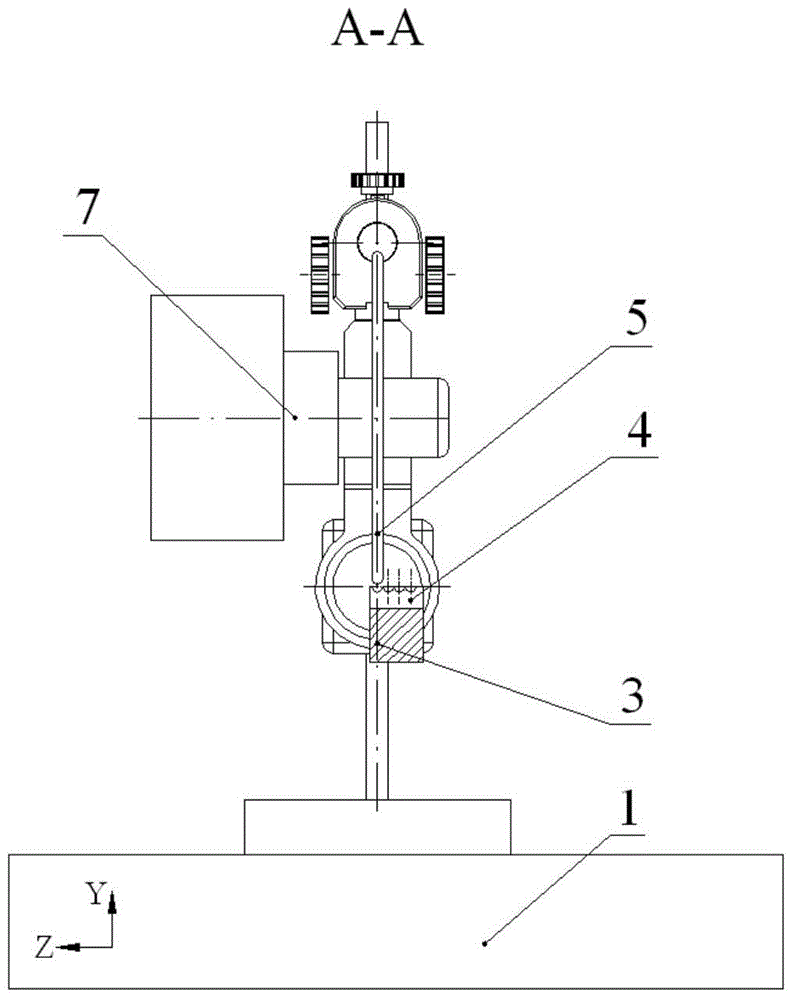

[0021] Specific Embodiment 1: The ultrasonic vibration-assisted polishing device for superhard material microstructure surface in this embodiment consists of a precision grinder workbench 1, a dynamometer 2, an ultrasonic vibration workbench 3, a superhard material profiling processing tool 5, and an optical microscope 6 It is composed of the spindle 7 of the precision grinding machine, the dynamometer 2 is located on the upper surface of the left side of the precision grinding machine table 1, the optical microscope 6 is located on the upper surface of the right side of the precision grinding machine table 1, and the ultrasonic vibration table 3 is located on the upper surface of the dynamometer 2 On the sensor and fixedly connected with it, so as to collect the change of the vertical polishing force in the processing area, the superhard material workpiece 4 is fixed on the end of the tool head 3-1 front end of the ultrasonic vibration table 3, and the tool head 3-1 follows the...

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment is different from Embodiment 1 in that: the superhard material workpiece is tungsten carbide, silicon carbide or silicon nitride. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific embodiment three: The method of using the ultrasonic vibration-assisted polishing device for the superhard material microstructure surface in this embodiment is realized through the following steps:

[0024] 1. Install the diamond profiling grinding wheel 5-1 on the precision grinding machine spindle 7, fix the superhard material workpiece 4 to the front end of the tool head 3-1 of the ultrasonic vibration table 3, and apply one-dimensional ultrasonic vibration. The three-dimensional vibration direction is the same as the feeding direction of the tool head 3-1, the rotational speed of the diamond profiling grinding wheel 5-1 is controlled to be 2000rpm-4000rpm, and the feeding speed of the precision grinding machine table 1 is controlled to be 0.2mm / min-2mm / min, and the alignment is completed. Precision grinding of superhard material workpiece 4;

[0025] 2. The diamond profiling grinding wheel 5-1 is removed, the profiling polishing wheel 5-2 is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com