Low-shrinkage light gypsum material and preparation method thereof

A gypsum material and low-shrinkage technology, which is applied in the field of building insulation materials, can solve the problems of shrinkage resistance research and lack of application, and achieve excellent shrinkage deformation resistance, reduce thermal conductivity, and improve compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

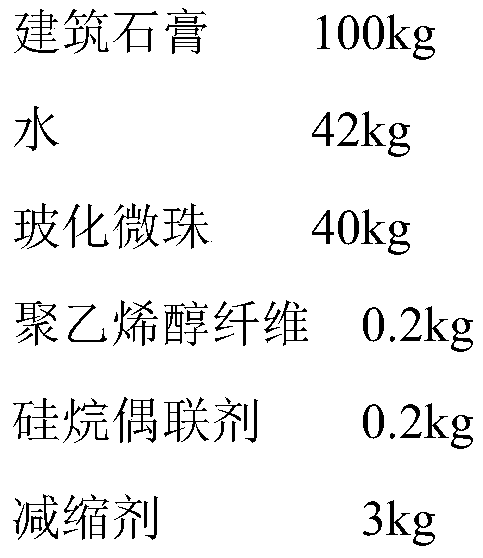

[0025] Taking the 100kg of building gypsum used to prepare the low-shrinkage lightweight heat-insulating gypsum material of the present invention as an example, the raw materials used and their quality are as follows:

[0026]

[0027]

[0028] The gelling material used in the above-mentioned present invention is desulfurized building gypsum powder, with a fineness of 200 μm sieve ≤ 10%; water adopts ordinary tap water; the bulk density of vitrified microbeads is 100-130kg / m 3 , the particle size is 1mm~3mm, the surface vitrification rate is ≥98%, the volume water absorption rate is ≤15%; polyvinyl alcohol fiber: the length is 3-10mm, the diameter is 15±3μm, and the density is 1.3g / cm 3 , the tensile strength is 1600MPa, the elastic modulus is 36GPa, and the elongation at break is 15%; the appearance of the silane coupling agent is a colorless or yellowish transparent liquid, the main component is methacryloxy functional group silane, and the purity is ≥98.5 %; the shrin...

Embodiment 2

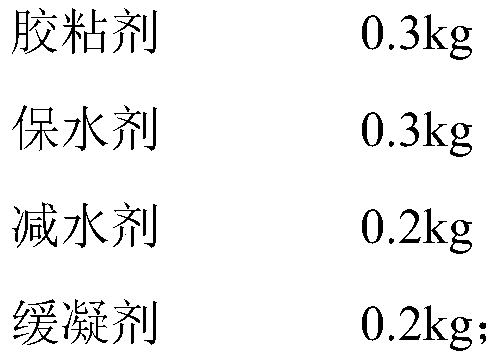

[0036] Taking the 100kg of building gypsum used to prepare the low-shrinkage lightweight heat-insulating gypsum material of the present invention as an example, the raw materials used and their quality are as follows:

[0037]

[0038] The specification and preparation method of the above-mentioned raw materials are the same as in Example 1.

Embodiment 3

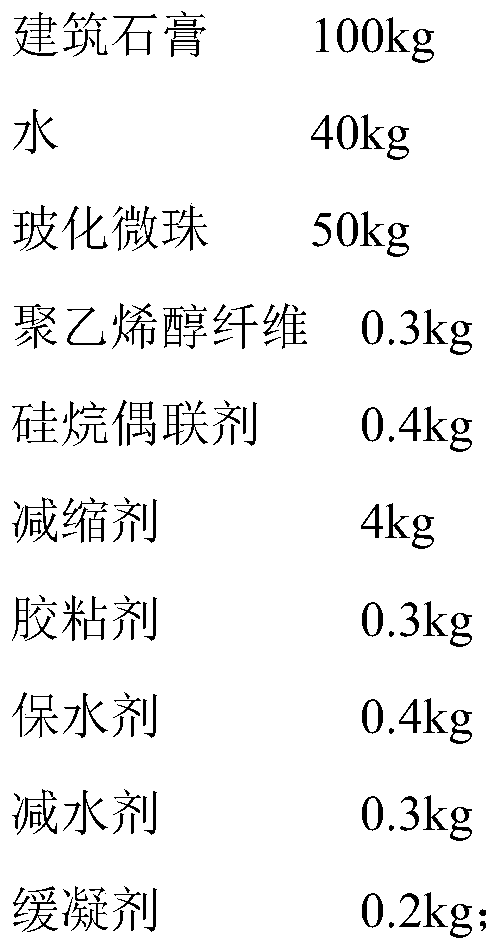

[0040] Taking the 100kg of building gypsum used to prepare the low-shrinkage lightweight heat-insulating gypsum material of the present invention as an example, the raw materials used and their quality are as follows:

[0041]

[0042]

[0043] The specification and preparation method of the above-mentioned raw materials are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com