Triple-effect evaporator for preparing organic liquid fertilizer

A technology of three-effect evaporator and liquid fertilizer, which is applied in the direction of organic fertilizer, multi-effect evaporation, evaporator accessories, etc., can solve the problem of reduced survival rate of bacteria, achieve the effect of increasing activity and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

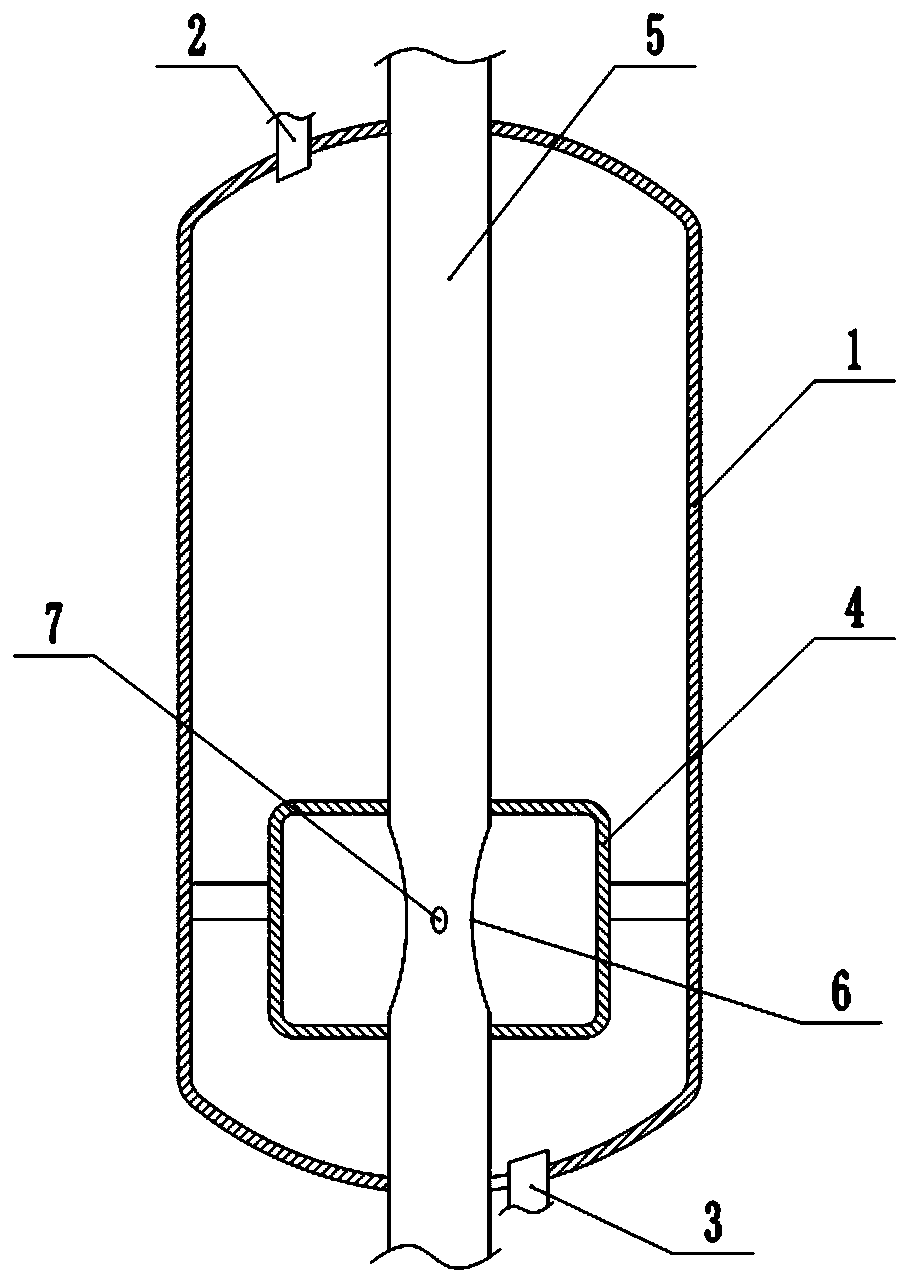

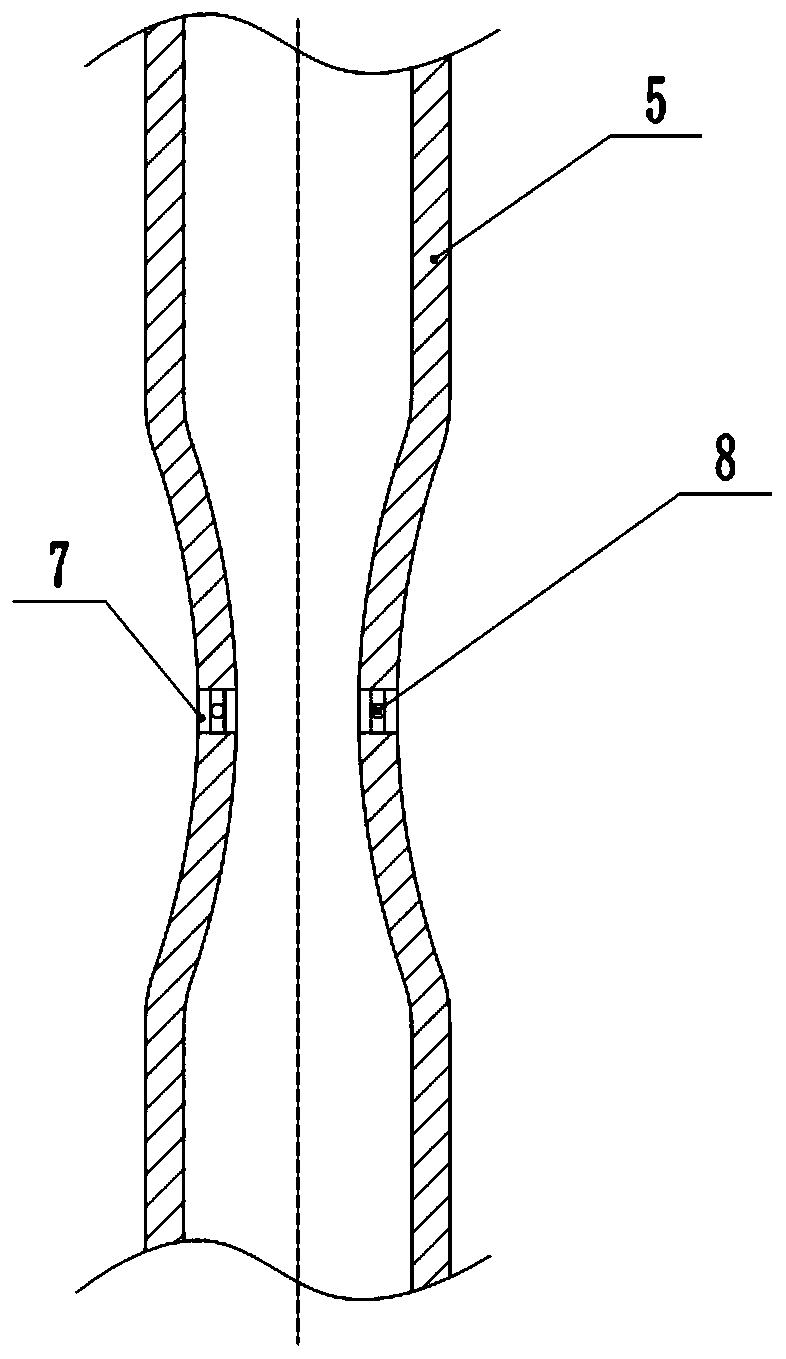

[0035] Embodiment 1 is basically as attached figure 1 and figure 2 Shown:

[0036] The three-effect evaporator for the preparation of organic liquid fertilizer includes a primary evaporator, a secondary evaporator and a tertiary evaporator connected in sequence, and a tail mixer is connected to the liquid outlet of the tertiary evaporator, wherein the tail mixer includes The insulation tank 1 is provided with a water inlet 2 on the top of the insulation tank 1, and a water outlet 3 is provided at the bottom of the insulation tank 1, and a cooling water circulation mechanism located outside the insulation tank 1 is provided between the water inlet 2 and the water outlet 3 (in the figure Not shown), the cooling water circulation mechanism includes a circulation pump and a water storage tank, the water outlet 3 communicates with the water storage tank through a pipeline, and the inlet of the circulation pump communicates with the water storage tank, and the outlet of the circul...

Embodiment 2

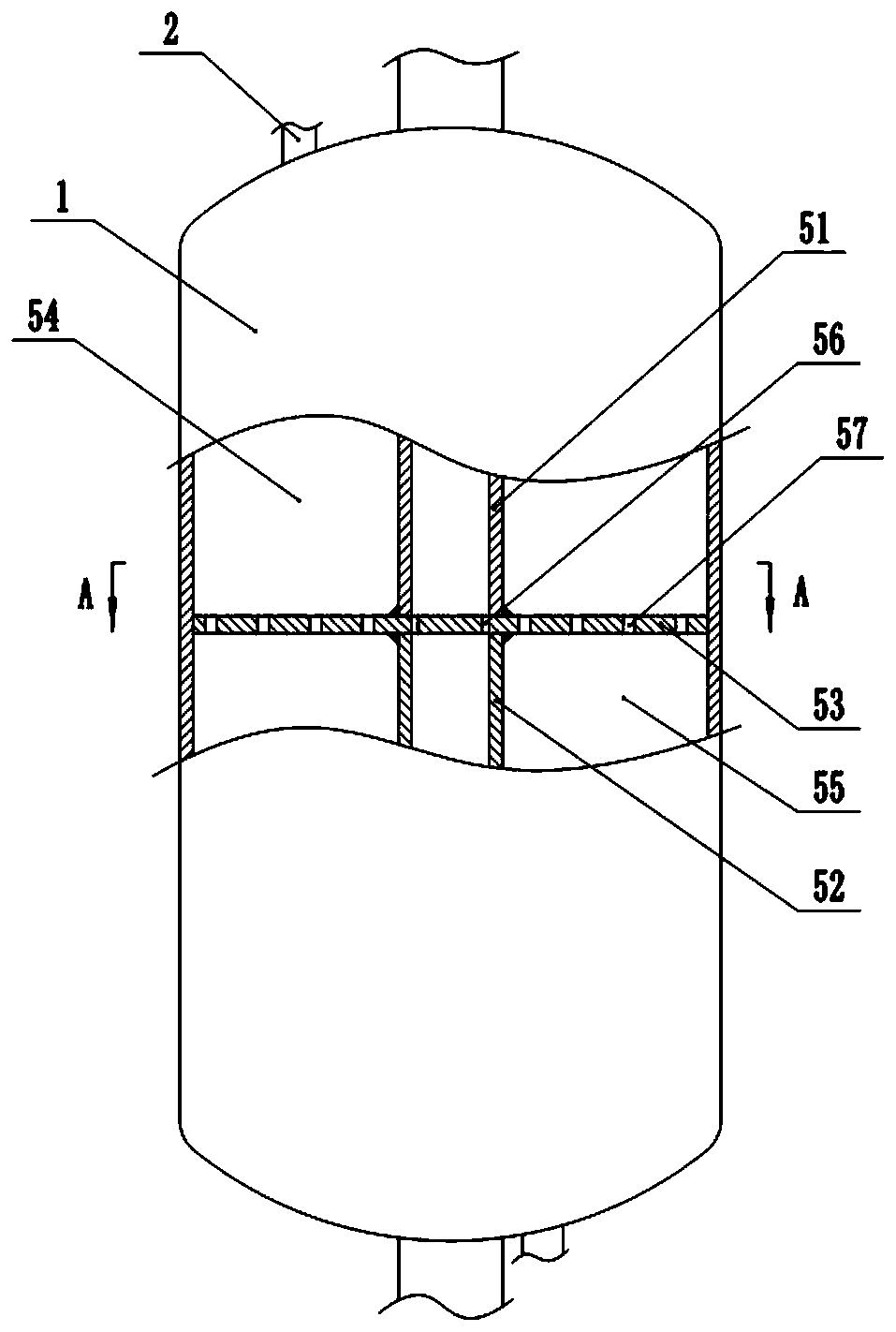

[0041] Embodiment 2 is basically as attached image 3 Shown:

[0042] The difference from Embodiment 1 is that the liquid inlet pipe 5 includes a heat exchange pipe 51 and a mixing pipe 52, and a partition 53 is fixed inside the insulation tank 1, and the partition 53 divides the insulation tank 1 into heat exchange tubes located above the partition 53. zone 54 and the heat preservation zone 55 located below the partition 53, the heat exchange tube 51 and the mixing tube 52 are fixed on the partition 53, the heat exchange tube 51 is located in the heat exchange zone 54, and the mixing tube 52 is located in the heat preservation zone 55, And the necking section 6 is located on the mixing tube 52, combined with Figure 4 As shown, a plurality of liquid outlet holes 56 located in the liquid inlet pipe 5 are opened on the separator 53, and the liquid outlet holes 56 are uniformly distributed along the central axis of the liquid inlet pipe 5, and the liquid outlet holes 56 are all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com