Vulcanizing agent and applications thereof

A vulcanizing agent, vulcanization and cross-linking technology, applied in organic chemistry, silicon organic compounds, chemical instruments and methods, etc., can solve problems such as reversible design of cross-linking methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

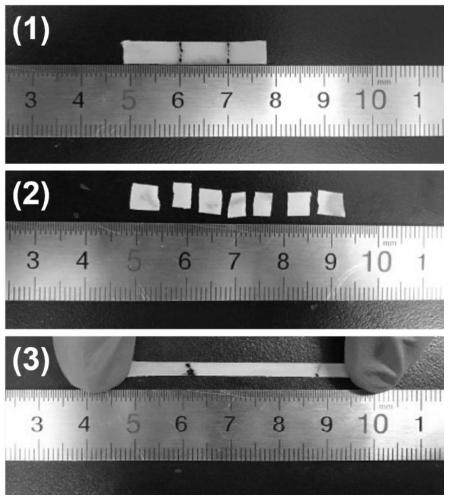

[0040] Preparation of novel vulcanizing agent:

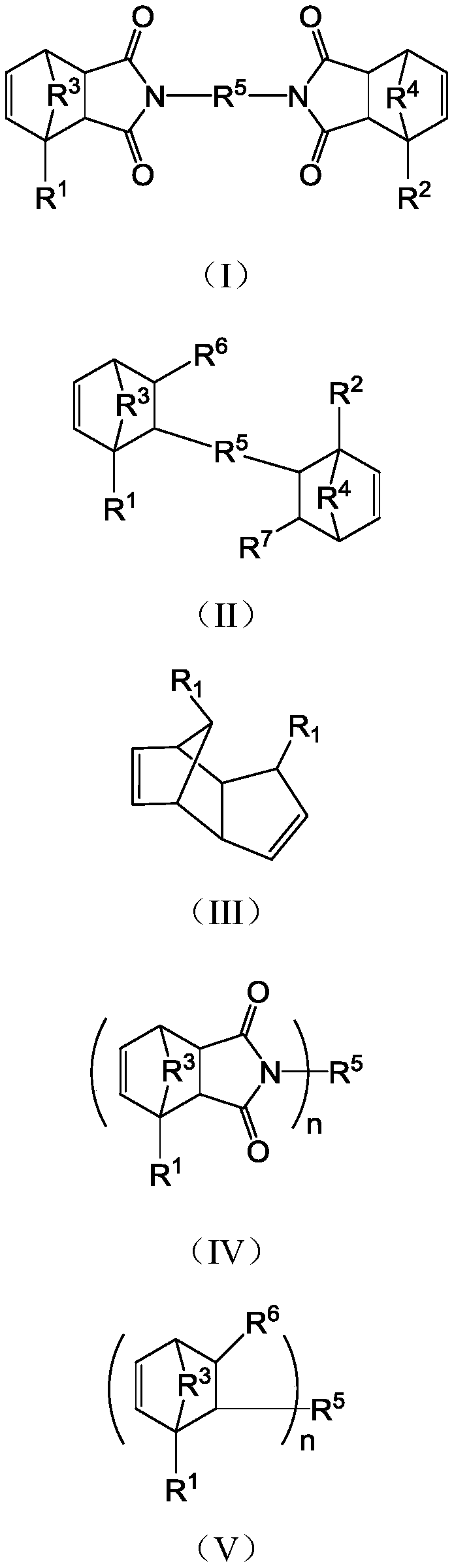

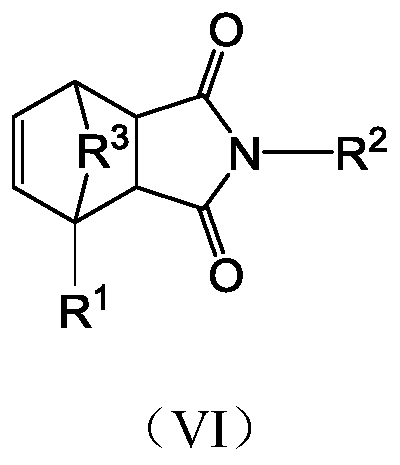

[0041] 1. A vulcanizing agent having a structure shown in formula (I)

[0042] The structural formula of vulcanizing agent A is:

[0043]

[0044] The synthesis method is shown in Reaction Scheme 1.

[0045] Synthesis of reactant ①: Add furfuryl alcohol (6.43 g, 0.07 mol) into 20 ml of sodium hydroxide (40 wt%) aqueous solution, and stir for 1 h. Afterwards, 10ml of toluene, 5g of 4-chloromethylstyrene and 4.25g of tetrabutylammonium hydroxide aqueous solution (40wt%) were added as catalysts to the above mixed solution, and reacted at room temperature for 48h. After the reaction was completed, excess water was added to the reaction solution, and extracted with ether. The organic phase was dried with anhydrous magnesium sulfate, filtered, and finally the organic solvent was removed by rotary evaporation to obtain the reactant ① with a yield of 76%.

[0046] The reactant ②N,N'-(4,4'-methylenediphenyl)bismaleimide is a comme...

Embodiment 2

[0087] In parts by mass, 100 parts of polypropylene (melt index MFR=2.0g / 10min, 230°C, the same below), 0.1 part of 1010 (antioxidant), 0.1 part of 168 (antioxidant), 0.1 part of 2,5 -Dimethyl-2,5-two (tert-butyl peroxy) hexane (initiator), 2 parts of vulcanizing agent A of the present invention are mixed, then the mixture is added to a 35-type twin-screw extruder (double Longkeya Nanjing Machinery Co., Ltd.) for melting. The temperature of the melting section of the extruder is 160°C, the temperature of the reaction section is 190°C, the temperature of the melt delivery section is 200°C, the temperature of the outlet is 180°C, the screw speed is set at 150rpm, and the extruded product is cooled by a circulating water bath and Cut into pellets to obtain the final product.

Embodiment 3

[0089] In parts by mass, 100 parts of polypropylene, 0.1 part of 1010 (antioxidant), 0.1 part of 168 (antioxidant), 0.2 part of 2,5-dimethyl-2,5-di(tert-butyl peroxy Base) hexane (initiator), 5 parts of vulcanizing agent A of the present invention are mixed, then the mixture is added to a 35-type twin-screw extruder for melting. The temperature of the melting section of the extruder is 160°C, the temperature of the reaction section is 190°C, the temperature of the melt delivery section is 200°C, the temperature of the outlet is 180°C, the screw speed is set at 150rpm, and the extruded product is cooled by a circulating water bath and Cut into pellets to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com