Preparation of a Bentonite Modified Hydrothermal Carbon Material and Its Application in Non-point Source Pollution Reduction

A technology of hydrothermal charcoal and soil improvement, applied in the direction of soil conditioning materials, applications, organic fertilizers, etc., can solve the problems of increasing ammonia volatilization in paddy soil, reduce ammonia volatilization non-point source pollution, improve N utilization rate and rice yield, Effect of increasing rice yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of bentonite modified hydrothermal carbon material, comprising the steps of:

[0029] 1) Preparation of solid hydrothermal charcoal: Mix sawdust with water, react for 1-2h at a pressure of 5-10MPa and a temperature of 210-230°C to obtain solid hydrothermal charcoal, the ratio of sawdust to water is 1:7-13w / v; collecting solid hydrothermal charcoal by centrifugation and drying to obtain dry solid hydrothermal charcoal;

[0030] 2) Preparation of bentonite thermally modified hydrothermal charcoal: grind dry solid hydrothermal charcoal into powdered hydrothermal charcoal; mix powdered hydrothermal charcoal and sodium-based bentonite according to a mass ratio of 3.5-4.5:1, and Heat treatment at 280-350° C. for 1-2 hours to obtain bentonite modified hydrothermal carbon material, cool naturally to room temperature, and pass through grading sieves.

[0031] Preferably, the wood chips are poplar wood chips, and the particle size of the poplar wood chips i...

Embodiment 1

[0038] The preparation of embodiment 1 bentonite modified hydrothermal carbon (CHC)

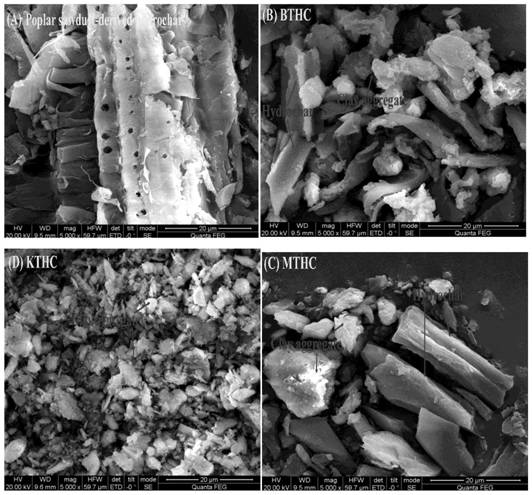

[0039] Hydrothermal charcoal production is carried out using poplar wood chips (ie, poplar sawdust) as raw material, and poplar wood chips are mixed with a reaction medium solvent (ie, water). Preparation of hydrothermal charcoal: stay at high pressure (8Mpa) at 220°C for one hour (reaction for 1 hour), and the solid-liquid ratio is 1:10 (w / v, g / mL). Solid hydrothermal charcoal produced by HTC (hydrothermal carbonization) was collected by centrifugation and dried at 70 °C until further reduction of undetectable masses. Then, grind the solid hydrothermal charcoal into a powder with a particle size of 1-2 mm, and mix it with bentonite, montmorillonite or kaolin at a ratio of 4:1 (mass ratio). Mix evenly, put into the crucible, and seal the cap, after that, place the crucible in a muffle furnace at 300°C for firing for 1 hour, and let it cool down to room temperature naturally. CHCs (i.e., cla...

Embodiment 2

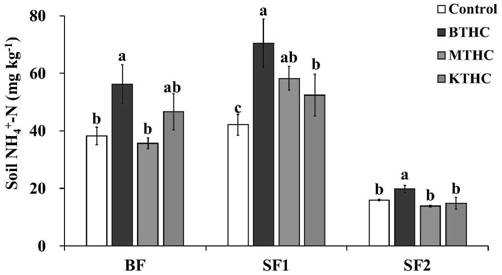

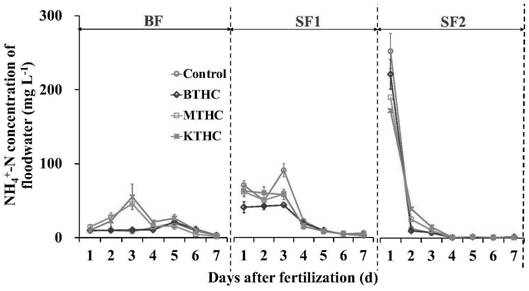

[0040] Embodiment 2 Soil column experiment setting

[0041] The paddy soil used in the soil column experiment was collected from the 0-20 cm topsoil of the paddy field at the Experimental Field of Nanjing Academy of Agricultural Sciences, Jiangsu Province. The soil characteristics are as follows: loam content 57%, sand content 21%, sand content 21%, pH 7.01 (solid-liquid ratio 1:2.5, g / mL), total nitrogen content 0.87g kg -1 , organic matter content 9.0g kg -1 , total phosphorus content 0.76g kg -1 , total potassium content 3.62g kg -1 . Each soil column is filled with 35kg of paddy soil. The paddy soil is naturally air-dried and passed through a 2 mm sieve, mixed evenly with the hydrothermal charcoal composite material, and loaded into a soil column (a soil column of PVC material with a diameter of 30 cm and a height of 50 cm). Specifically, 3 days before rice transplanting, paddy field soil was fully mixed with bentonite-hydrothermal charcoal composite (BTHC), montmoril...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com