Flexible substrate and preparation method thereof

A flexible substrate and substrate technology, which is applied in the direction of final product manufacturing, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of poor film bending, poor adhesion, and the inability of traditional flexible substrates to meet the needs of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

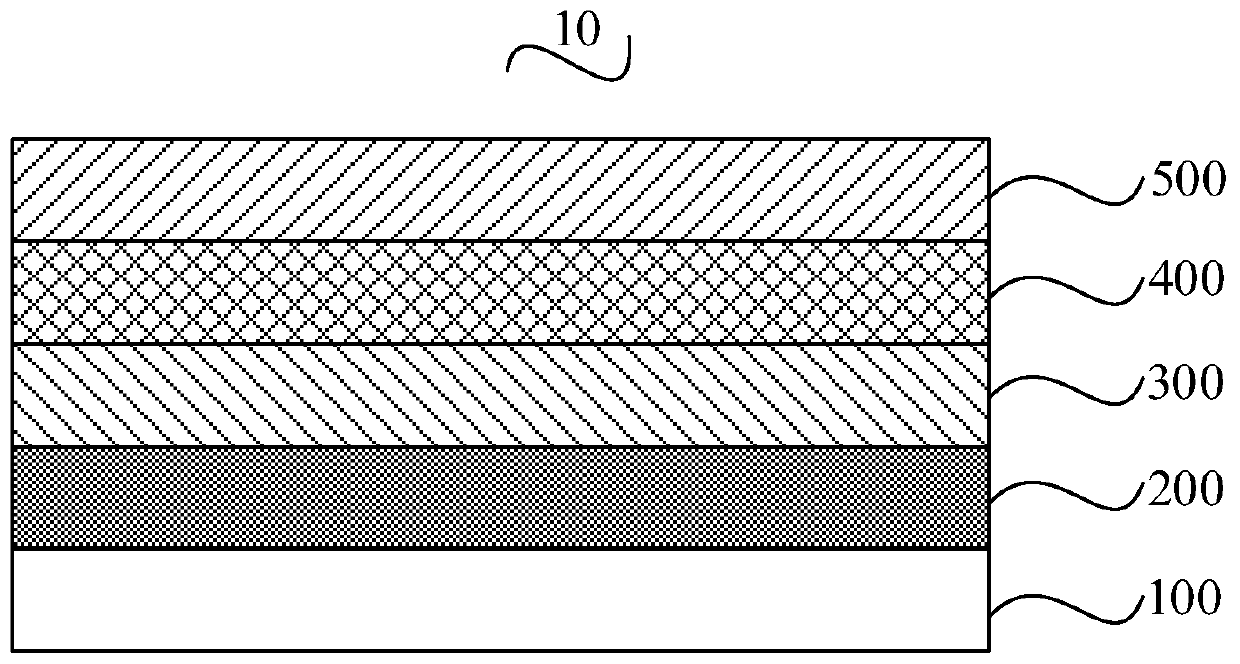

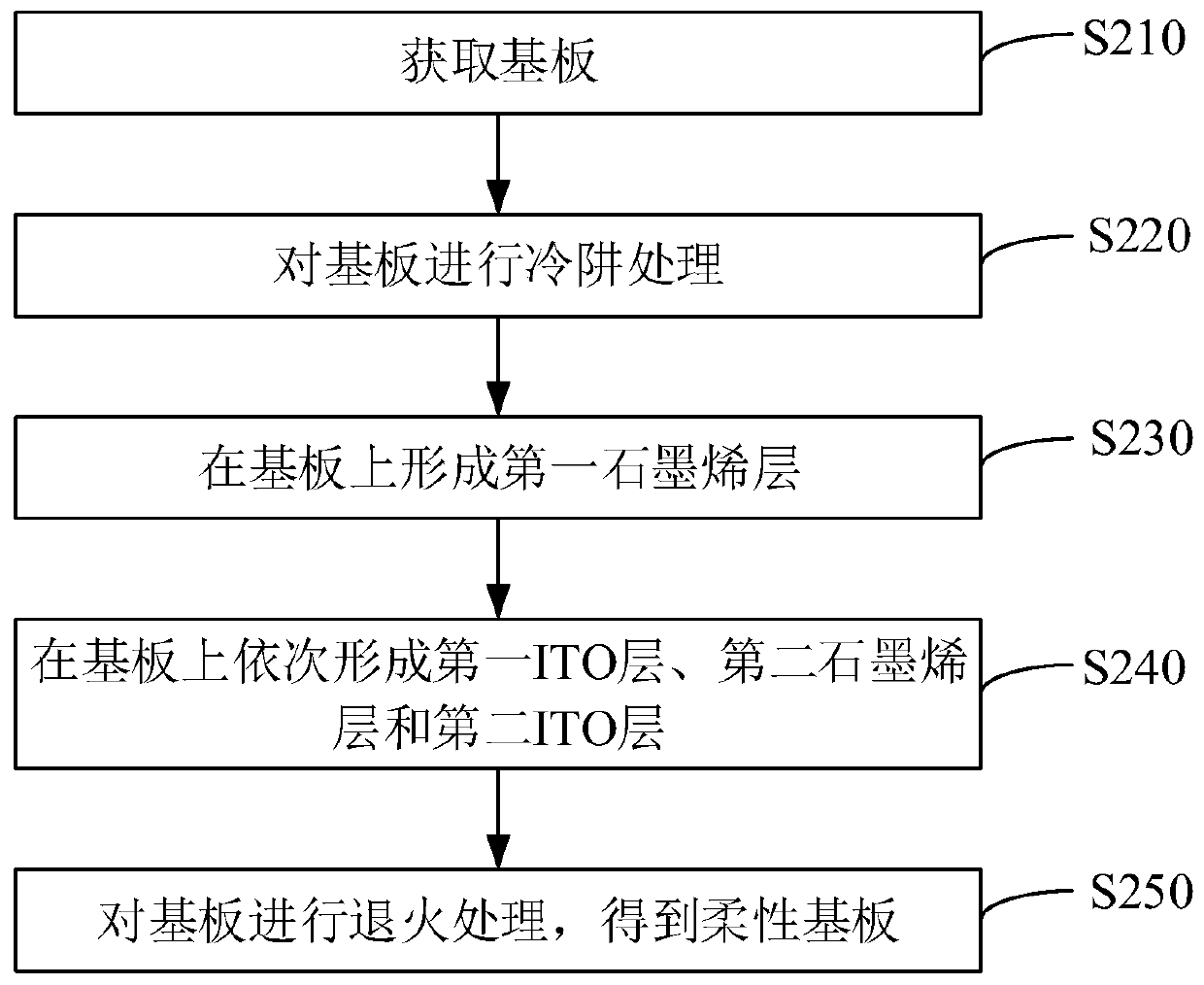

[0035] see figure 2 , the preparation method of the flexible substrate of an embodiment comprises the following steps:

[0036] Step S210: providing a substrate.

[0037] Wherein, the substrate is a polyethylene terephthalate (PET) film substrate or a polyimide (PI) film substrate. The thickness of the substrate is 0.01 mm to 0.50 mm.

[0038] Further, after providing the substrate, a step of cleaning the substrate is also included. Specifically, the step of cleaning the substrate includes: scrubbing the substrate, then ultrasonically cleaning the substrate with deionized water and ultrasonic cleaning with alcohol, and finally drying the substrate in alcohol vapor. When the substrate is removed from the alcohol vapor, the substrate is quickly dried completely because the condensed vapor evaporates from the surface.

[0039] Further, alcohol is used to scrub the substrate to preliminarily remove dust and oil stains on the surface of the substrate, so as to avoid affecting ...

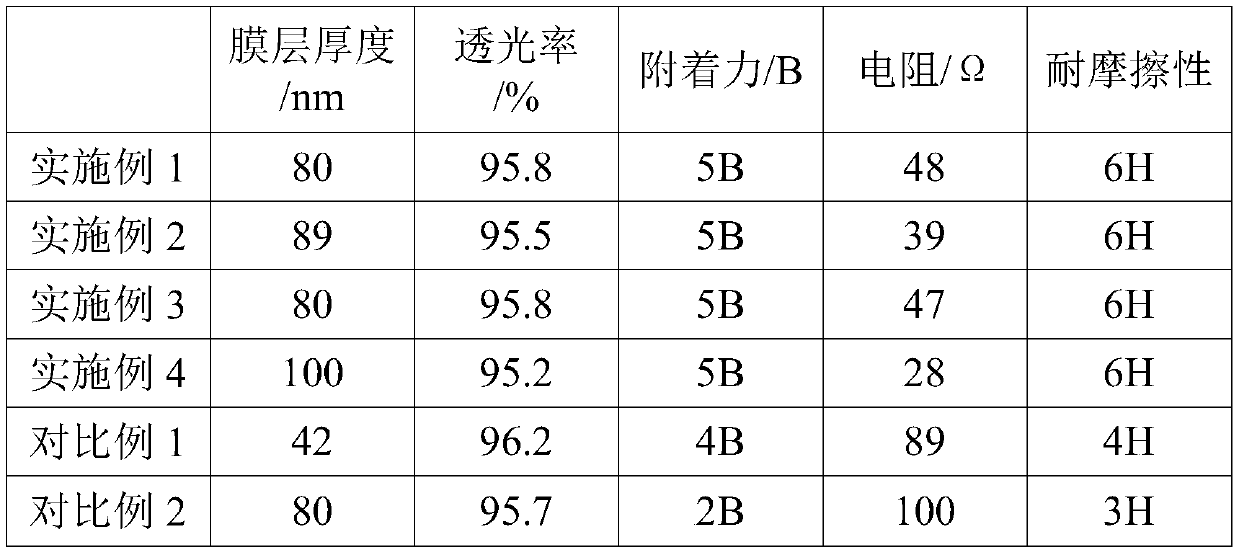

Embodiment 1

[0071] The preparation process of the flexible substrate of this embodiment is as follows:

[0072] (1) Scrub the substrate with alcohol, then place it in deionized water for ultrasonic cleaning for 3 minutes with an ultrasonic power of 1000W, and then place it in alcohol for ultrasonic cleaning for 3 minutes with an ultrasonic power of 1000W. After sonication, the substrate was dried in alcohol vapor. Wherein, the substrate is a PET film substrate, and the thickness of the substrate is 0.12mm.

[0073] (2) Place the substrate cleaned in step (1) on the jig, and process it with a cold trap device at -130° C. for 1 min.

[0074] (3) The substrate processed by the cold trap is placed in the No. 1 sputtering chamber, and the graphene is used as the target material to perform sputtering on the substrate in a mixed atmosphere of dry air and argon. Among them, the voltage is 300V, the bias voltage is -70V, the power is 550W, the target distance is 40mm, and the vacuum degree is 2....

Embodiment 2

[0078] The preparation process of the flexible substrate of this embodiment is as follows:

[0079] (1) Scrub the substrate with alcohol, then place it in deionized water for ultrasonic cleaning for 4 minutes with an ultrasonic power of 1500W, and then place it in alcohol for ultrasonic cleaning for 4 minutes with an ultrasonic power of 1500W. After sonication, the substrate was dried in alcohol vapor. Wherein, the substrate is a PET film substrate, and the thickness of the substrate is 0.12 mm.

[0080](2) Place the substrate cleaned in step (1) on the jig, and process it with a cold trap device at -145° C. for 3 minutes.

[0081] (3) The substrate processed by the cold trap is placed in the No. 1 sputtering chamber, and the graphene is used as the target material to perform sputtering on the substrate under the atmosphere of dry air and argon. Among them, the voltage is 350V, the bias voltage is -95V, the power is 950W, the target distance is 75mm, and the vacuum degree is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com