Regeneration method and device for acid gas-containing solvent

A technology of acid gas and regeneration device, which is applied in the chemical industry, can solve the problems of large steam consumption, serious solvent degradation, and high equipment investment, and achieve the effects of strong penetration, fast heating speed, and investment saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Flue gas capture CO 2 The device uses amine solution as the absorbent to absorb carbon dioxide in the flue gas, and the treated flue gas volume (dry basis) is 550600Nm 3 / h, the carbon dioxide content in the flue gas is 14.45%, and the flue gas temperature is 45°C; in the amine solution for absorbing carbon dioxide, the total concentration of organic amines (comprising monoethanolamine, methyldiethanolamine, diethanolamine, piperazine) is 20% by weight, the rest is water, the flow rate of the amine solution is 3200Nm 3 / h; After the flue gas is decarbonized, the capture rate of carbon dioxide by the amine solution is 82%.

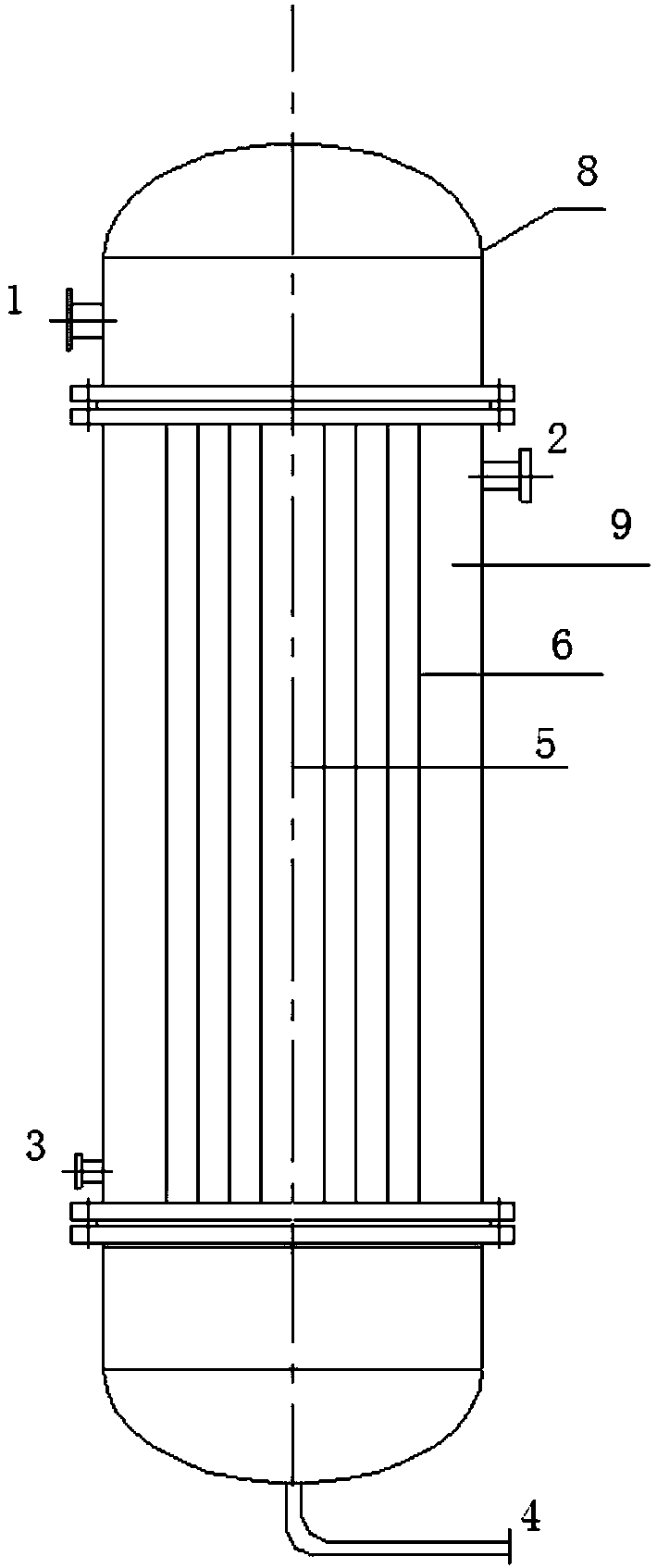

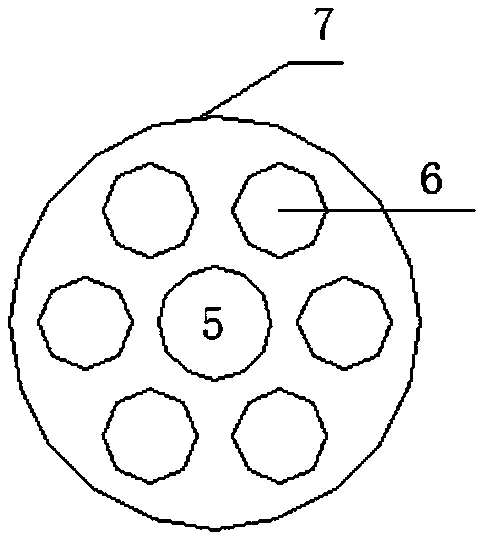

[0043] Using the present invention figure 1 The regeneration device shown in the figure deals with the amine solution that has absorbed carbon dioxide. The amine solution enters the inlet area through the solvent inlet 1, and flows into the degassing pipe 6 through the inlet on the first separator. The microwave transmitter in the microwave emittin...

Embodiment 2

[0048] A set of purification system for removing hydrogen sulfide in natural gas, using MDEA (methyldiethanolamine) aqueous solution (MDEA concentration: 30% by weight) as absorbent to absorb hydrogen sulfide in natural gas, natural gas processing capacity 200Nm 3 / h, the absorption operating pressure is 8.3MPa, and the hydrogen sulfide content in the purified natural gas is less than 200ppm.

[0049] Using the present invention figure 1 The shown regenerative device handles the MDEA aqueous solution that has absorbed hydrogen sulfide. The MDEA aqueous solution enters the inlet area through the solvent inlet 1, flows into the degassing pipe 6 through the inlet on the first partition, and the microwave emitter in the microwave emitting pipe 5 emits microwaves. Microwave heating the MDEA aqueous solution in the degassing tube, the microwave processing power is 10kW-60kW (based on the amount of solvent 1t / h), the average microwave processing time of the solution is 2-4min, and th...

Embodiment 3

[0054] A set of purification system for removing hydrogen sulfide in natural gas, using MDEA aqueous solution (MDEA concentration: 30% by weight) as absorbent to absorb hydrogen sulfide in natural gas, natural gas processing capacity 4000Nm 3 / h, the absorption operating pressure is 3.5MPa, and the hydrogen sulfide content in the purified natural gas is less than 100ppm.

[0055] Using the present invention figure 1 The shown regenerative device handles the MDEA aqueous solution that has absorbed hydrogen sulfide. The MDEA absorbent enters the inlet area through the solvent inlet 1, flows into the degassing pipe 6 through the inlet on the first partition, and the microwave emitter in the microwave emitting pipe 5 emits microwaves. , carry out microwave heating on the MDEA aqueous solution in the degassing pipe, the microwave processing power is 10kW-90kW (based on the amount of solvent 1t / h), the average microwave processing time of the solution is 2-4min, and the hydrogen sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com