a rhpx/g-c 3 no 4 Composite photocatalyst and its preparation method and application

A composite catalyst, g-c3n4 technology, used in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. The effect of improving the activity of hydrogen production from water splitting and expanding the response range of visible light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

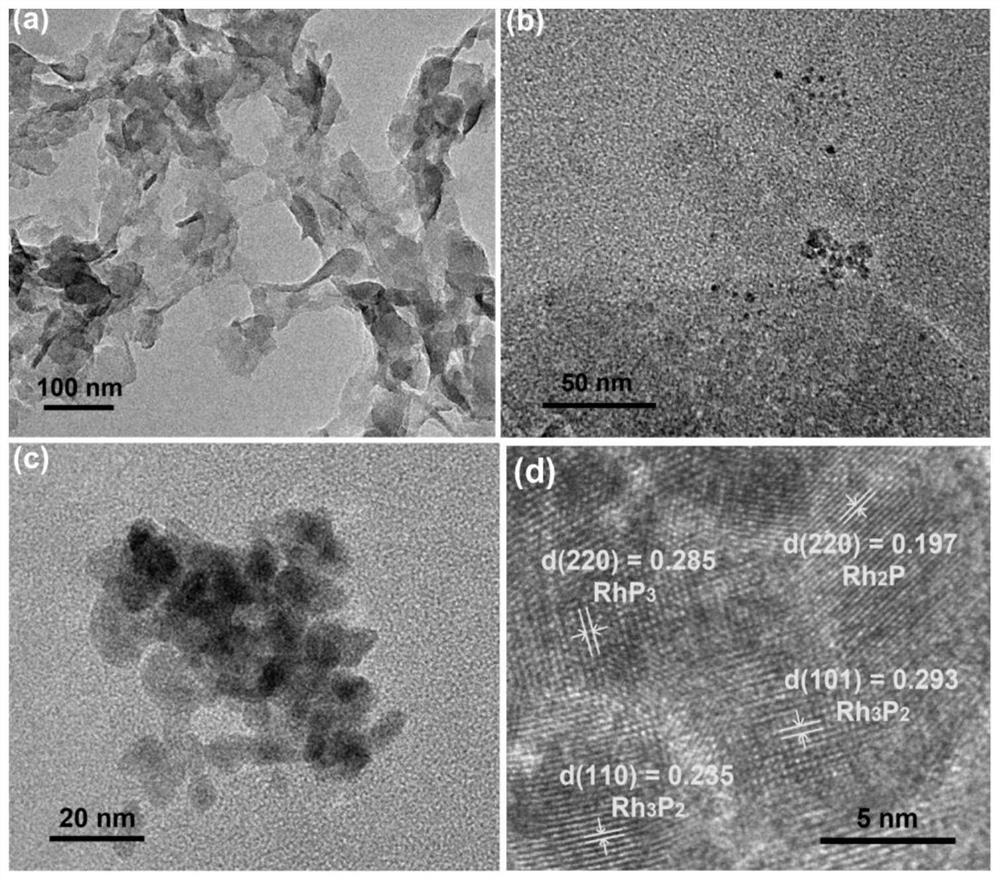

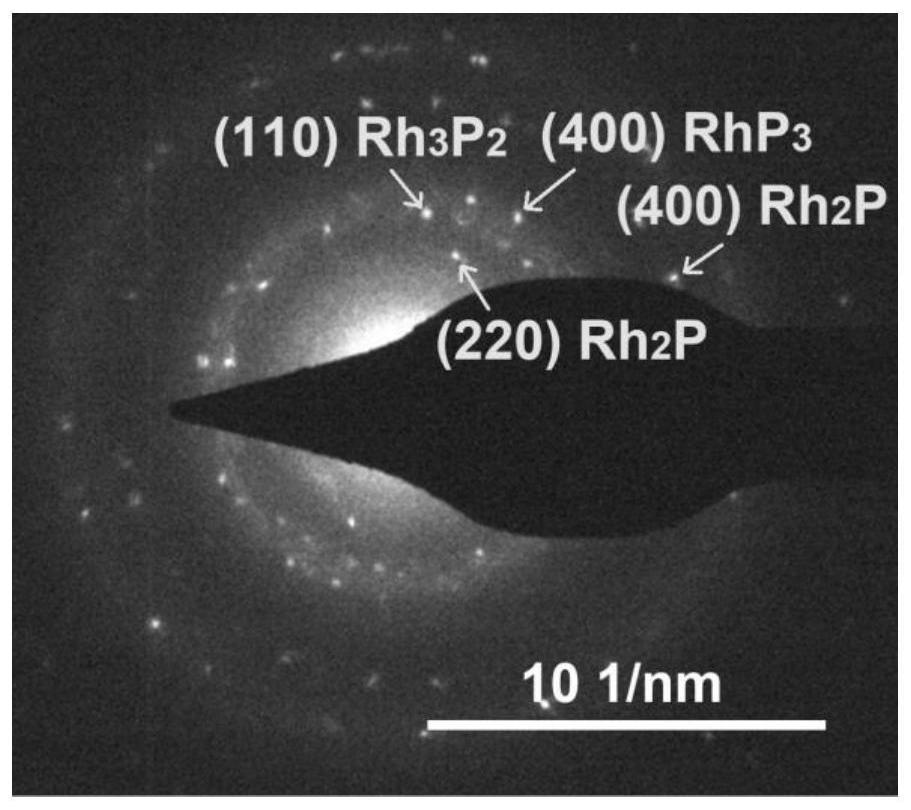

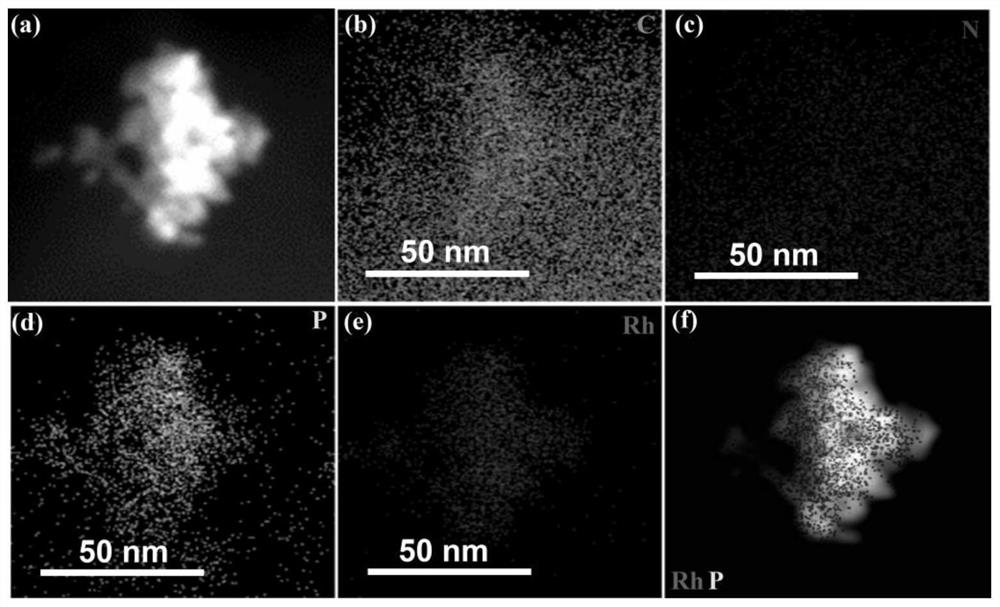

[0036] Example 1: RhP x / g -C 3 N 4 -1 Preparation of photocatalyst and its photolysis of water to produce hydrogen

[0037] (1) Preparation of ultra-thin g-C 3 N 4 Nanosheets:

[0038] Weigh a certain amount of urea, dry it in an oven at 80°C overnight, then grind it into a powder form and put it into a crucible with a lid. -1 The heating rate was raised to 550°C and calcined for 4h. After naturally cooling down to room temperature, the calcined product was taken out and stirred overnight in an appropriate amount of concentrated nitric acid (pH=1), then washed several times with deionized water until the pH of the filtrate was consistent with that of deionized water, and dried thoroughly in an oven to obtain g-C 3 N 4 .

[0039] Weigh 2g g-C 3 N 4 , from room temperature to 5°C min in the muffle furnace -1 The heating rate was increased to 500 ° C, and calcined for 4 h to obtain ultra-thin g-C 3 N 4 Nanosheets.

[0040] (2) Preparation of RhP x / g -C 3 N 4 -1...

Embodiment 2

[0045] Example 2: RhP x / g -C 3 N 4 -3 Preparation of photocatalyst and its photolysis of water to produce hydrogen

[0046] Step (1) is the same as in Example 1.

[0047] (2) Preparation of RhP x / g -C 3 N 4 -3 Photocatalyst:

[0048] Weigh 0.2g ultra-thin g-C 3 N 4 , dissolved in deionized water, and ultrasonically stirred to obtain a uniformly dispersed suspension. Accurately weigh rhodium triacetylacetonate, metal Rh and ultra-thin g-C 3 The mass ratio of N is 3:100, dissolved in deionized water, at this time the metal Rh is in the ultrathin g-C 3 N 4 With a loading of 3%, rhodium triacetylacetonate solution was added dropwise to the ultrathin g-C 3 N 4 The suspension was stirred by magnetic force for 3h. Then add 0.15 mol / L NaOH solution drop by drop to the suspension, and the molar ratio of metal Rh to sodium hydroxide n(Rh):n(NaOH)=1:2, magnetic stirring for 1h, 80°C oil bath overnight .

[0049] Grind the sample dried in the oil bath to powder, mix it w...

Embodiment 3

[0052] Example 3: RhP x / g -C 3 N 4 -5 Preparation of photocatalyst and its photolysis of water for hydrogen production

[0053] Step (1) is the same as in Example 1.

[0054](2) Preparation of RhP x / g -C 3 N 4 -5 Photocatalyst:

[0055] Weigh 0.2g ultra-thin g-C 3 N 4 , dissolved in deionized water, and ultrasonically stirred to obtain a uniformly dispersed suspension. Accurately weigh rhodium triacetylacetonate, metal Rh and ultra-thin g-C 3 N 4 The mass ratio is 5:100, dissolved in deionized water, at this time the metal Rh is in the ultrathin g-C 3 N 4 With a loading of 5%, rhodium triacetylacetonate solution was added dropwise to the ultrathin g-C 3 N 4 The suspension was stirred by magnetic force for 3h. Then add a certain amount of 0.15mol / L NaOH solution drop by drop to the suspension, and the molar ratio of metal Rh to sodium hydroxide n(Rh):n(NaOH)=1:2, magnetic stirring for 1h, 80℃ oil Bath overnight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com