CNT-B4C-TiB2 composite ceramic and preparation method thereof

A technology of cnt-b4c-tio2 and cnt-b4c-tib2, which is applied in the field of CNT-B4C-TiB2 composite ceramics and its preparation, can solve the problems of harsh sintering temperature and low density of composite ceramics, so as to improve performance and guarantee Toughening effect, the effect of ensuring uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

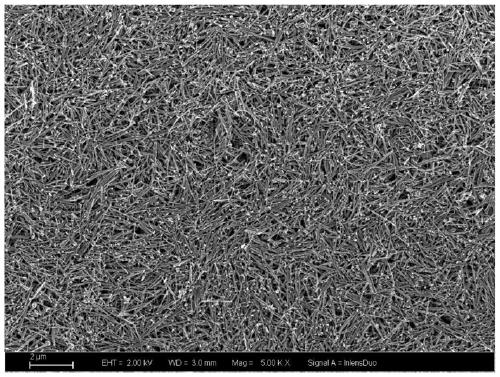

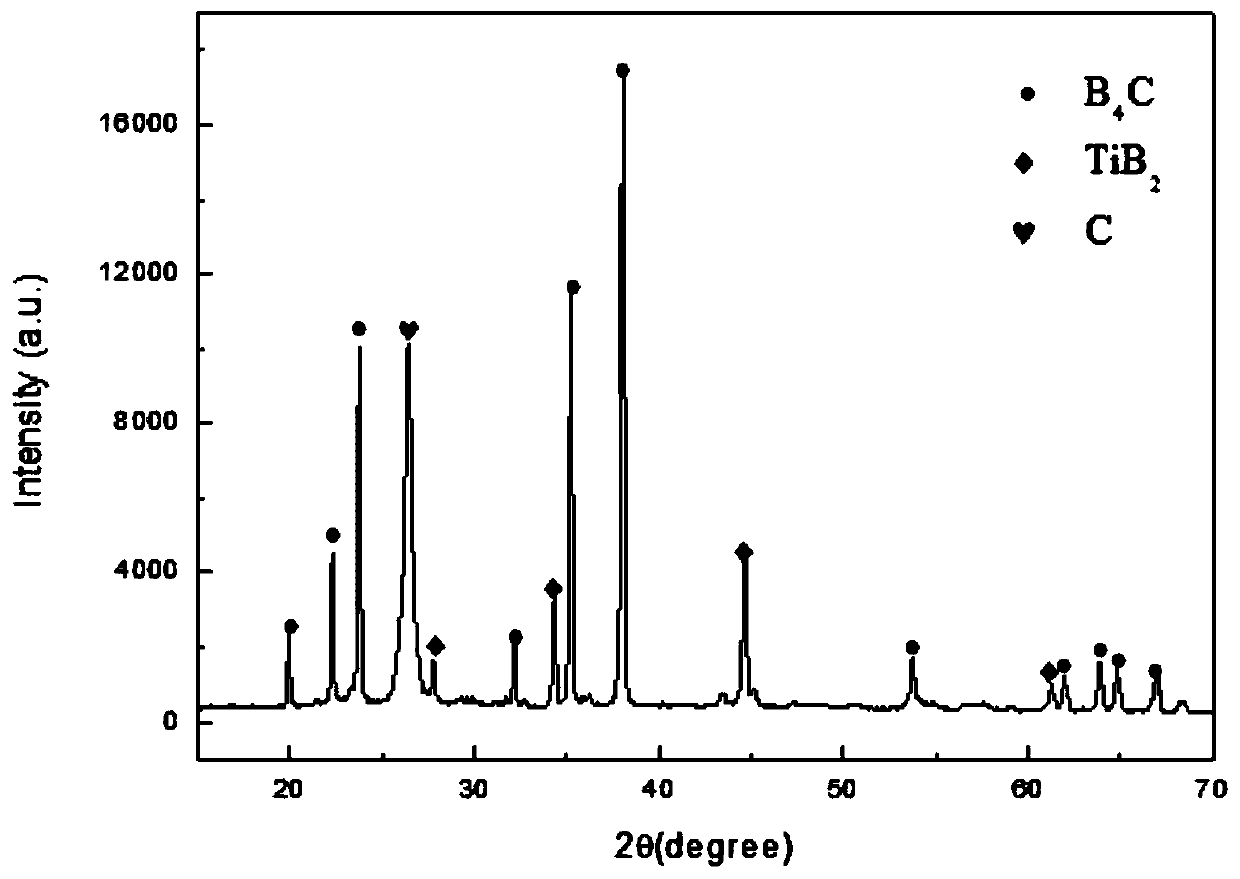

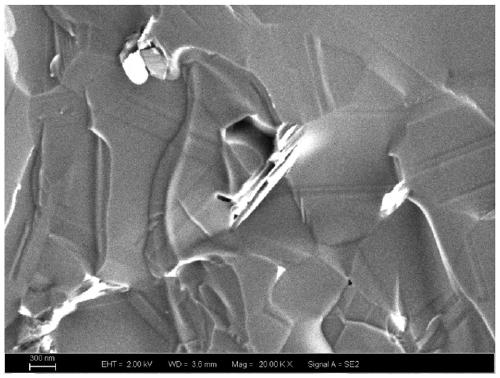

[0019] The embodiment of the present invention relates to a kind of CNT-B 4 C-TiB 2 The preparation method of composite ceramics comprises the following steps:

[0020] S1, mix the CNT dispersion with B 4 C nano powder, TiO 2 Mix nano powder and phenolic resin and stir evenly to get CNT-B 4 C-TiO 2 Composite slurry;

[0021] S2, CNT-B 4 C-TiO 2 The composite slurry is spray granulated to obtain CNT-B 4 C-TiO 2 Compound dry powder;

[0022] S3, the CNT-B 4 C-TiO 2 The composite dry powder is laid in the mold, compacted, and sintered in two stages under vacuum; the first stage is heated to 1500-1700°C at a rate of 5-20°C / min, and kept for 0.5-1h, and the second stage is 5- Raise the temperature to 1900-2200°C at a rate of 20°C / min and keep it for 1-2h to prepare CNT-B 4 C-TiB 2 Composite ceramics.

[0023] The CNT dispersion is obtained by mixing CNT, PVP (polyvinyl pyrrolidone, polyvinylpyrrolidone) and H 2 O mixed, obtained by ultrasonic treatment and stirring ...

Embodiment 1

[0030] This embodiment relates to a kind of CNT-B 4 C-TiB 2 The preparation method of composite ceramics comprises the following steps:

[0031] S1, CNT-B 4 C-TiO 2 Preparation of composite slurry;

[0032] S11, preparing a CNT dispersion;

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com