Preparation method of magnetic melamine hydrophobic oleophylic sponge

A technology of melamine sponge and melamine, applied in the direction of separation methods, chemical instruments and methods, and other chemical processes, can solve problems such as marine pollution and oil spills, and achieve simple preparation methods, less time-consuming, and good hydrophobic and lipophilic properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

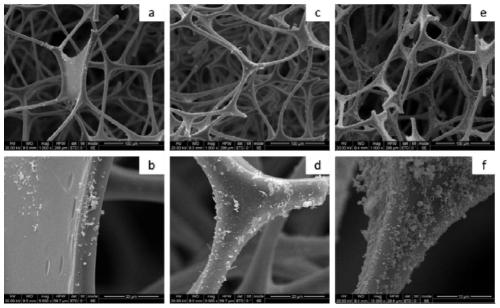

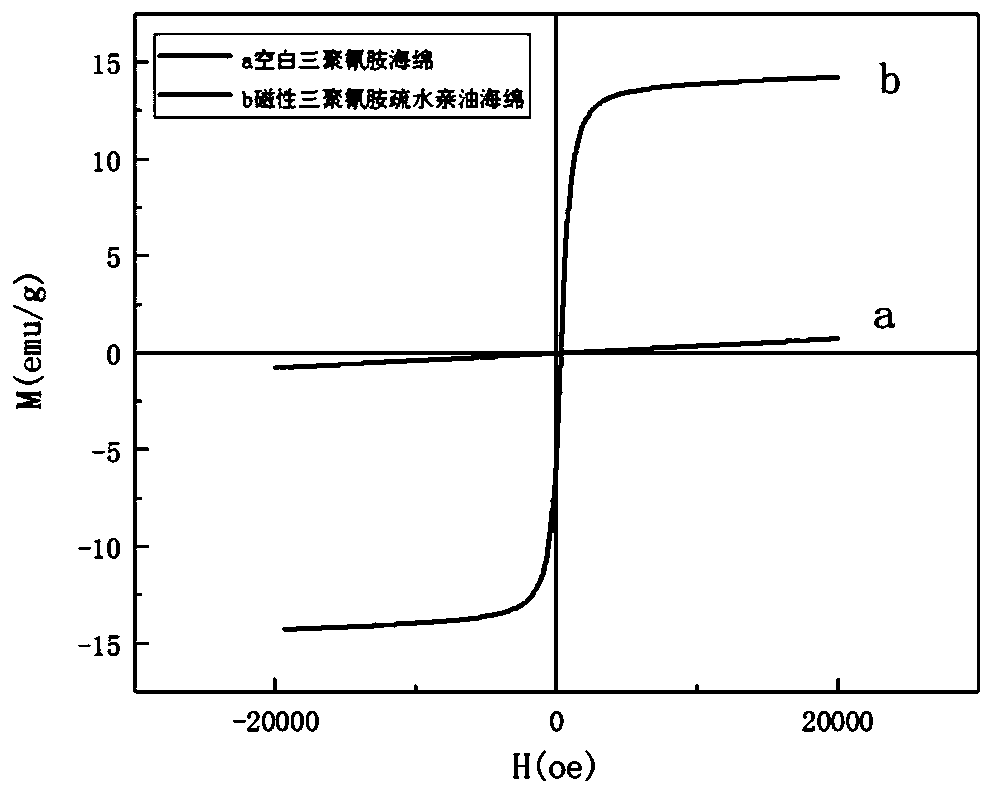

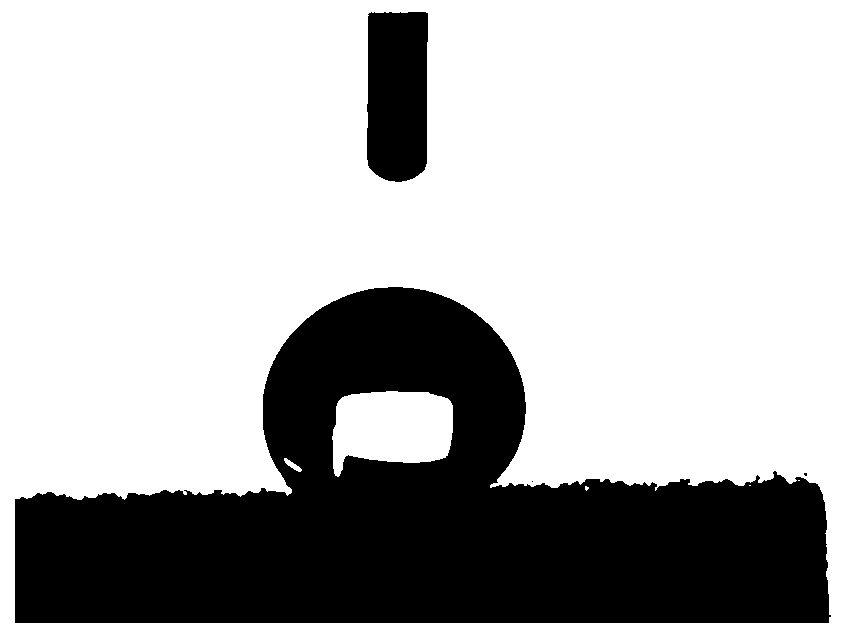

[0022] A melamine sponge with a volume of 1×1×2 cm is selected and placed at the bottom of the beaker. Prepare a toluene solution of amyltrichlorosilane with a mass fraction of 0.5%, pour it into the beaker where the sponge is placed, and the solution needs to completely submerge the sponge. After soaking for 30min, the modified solution in the sponge was squeezed out and washed with toluene three times. Put the sponge in a fume hood, and dry it in an oven at 120°C for 1 hour after the solvent evaporates completely. Weigh 150mg of magnetic 200nmFe 3 o 4 Nanoparticles, ultrasonically dispersed in 30 mL of absolute ethanol, formulated to a concentration of 5 mg / mL Fe 3 o 4 ethanol dispersion. Submerge the modified sponge in the dispersion liquid, sonicate for 10 minutes, take it out and dry it in an oven at 60°C for 2 hours to obtain a magnetic melamine hydrophobic and lipophilic sponge.

Embodiment 2

[0024] A melamine sponge with a volume of 1×1×2 cm is selected and placed at the bottom of the beaker. Prepare a toluene solution of propyltrichlorosilane with a mass fraction of 0.5%, pour it into the beaker where the sponge is placed, and the solution needs to completely submerge the sponge. After soaking for 30min, the modified solution in the sponge was squeezed out and washed with toluene three times. Put the sponge in a fume hood, and dry it in an oven at 120°C for 1 hour after the solvent evaporates completely. Weigh 150mg of magnetic 200nmFe 3 o 4 Nanoparticles, ultrasonically dispersed in 30 mL of absolute ethanol, formulated to a concentration of 5 mg / mL Fe 3 o 4 ethanol dispersion. Submerge the modified sponge in the dispersion liquid, sonicate for 10 minutes, take it out and dry it in an oven at 60°C for 2 hours to obtain a magnetic melamine hydrophobic and lipophilic sponge.

Embodiment 3

[0026] A melamine sponge with a volume of 1×1×2 cm is selected and placed at the bottom of the beaker. Prepare a toluene solution of methyltrichlorosilane with a mass fraction of 0.5%, pour it into the beaker where the sponge is placed, and the solution needs to completely submerge the sponge. After soaking for 30min, the modified solution in the sponge was squeezed out and washed with toluene three times. Put the sponge in a fume hood, and dry it in an oven at 120°C for 1 hour after the solvent evaporates completely. Weigh 150mg of magnetic 200nmFe 3 o 4 Nanoparticles, ultrasonically dispersed in 30 mL of absolute ethanol, formulated to a concentration of 5 mg / mL Fe 3 o 4 ethanol dispersion. Submerge the modified sponge in the dispersion liquid, sonicate for 10 minutes, take it out and dry it in an oven at 60°C for 2 hours to obtain a magnetic melamine hydrophobic and lipophilic sponge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com