Method of preparing high-density grating through femtosecond laser weak ablation and small-included-angle interference

A femtosecond laser, high-density technology, used in laser welding equipment, diffraction gratings, optics, etc., can solve problems such as increasing production costs and increasing the complexity of etching, to ensure regularity, strong anti-interference ability, and economical operation. efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

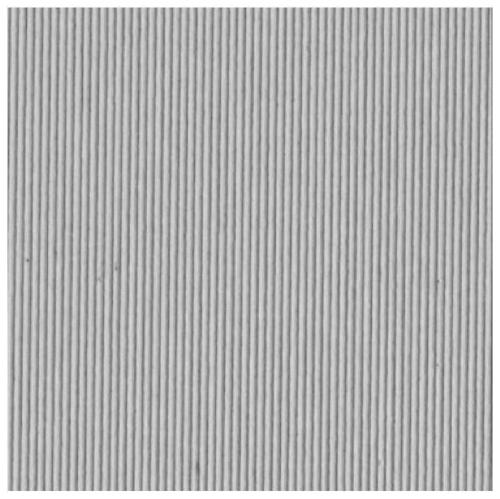

[0045] The sample is a silicon wafer, and a high-density grating is prepared on it, including:

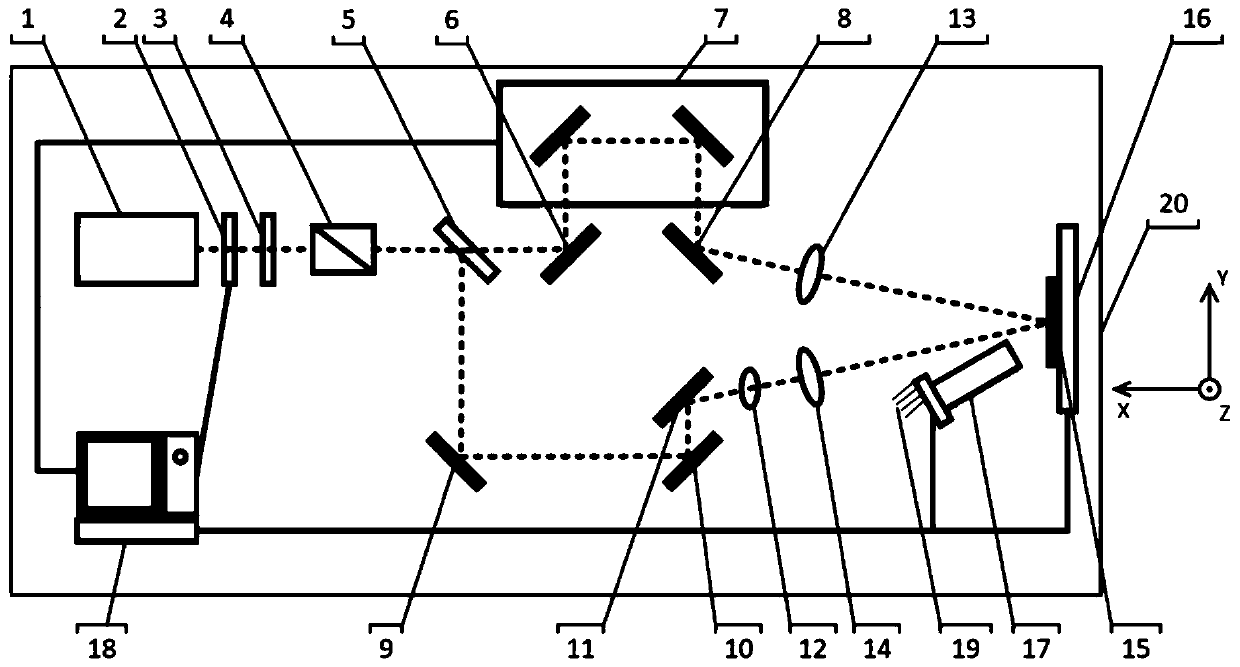

[0046] 1) build figure 1 The shown dual-beam femtosecond laser interference system makes the laser beam converge on the sample stage through the optical paths of the first cylindrical lens and the second cylindrical lens respectively. After converging, the spot size is 0.05*1.8mm, and the energy density is 0.136J / cm 2 ;

[0047] 2) Set processing conditions

[0048] Control the two laser beams at a small angle of 6.2° to ensure that the two beams of light are more likely to be coherent in time and space, reducing processing difficulty and making processing more stable and efficient. 0.136J / cm below the ablation threshold of the sample 2 Etching is carried out to avoid the generation of ejecta;

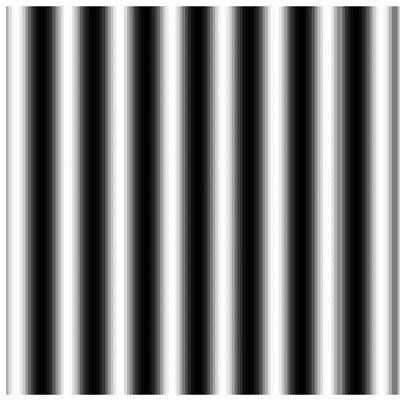

[0049] 3) Fabrication of large-area periodic nanogratings by weak ablation and small-angle interferometry

[0050] Firstly, put the silicon wafer in ethanol for 30min ultrasonic clean...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com