VOCs separation and degradation film and preparation method thereof

A technology for degrading thin films and active components, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high energy consumption, low separation and degradation efficiency of VOCs, etc., and achieve improved separation and degradation efficiency, excellent performance, To achieve the effect of complete degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

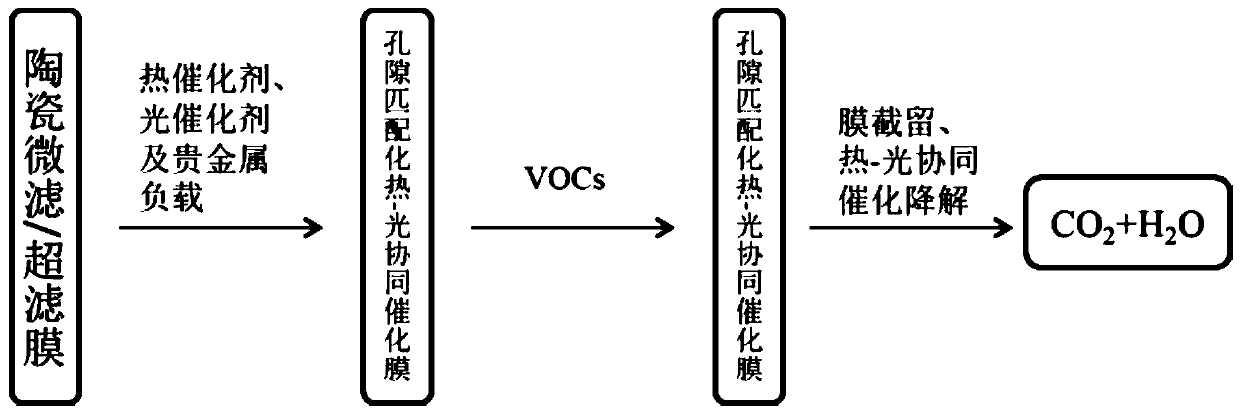

[0033] as attached figure 1 As shown, the present invention provides a kind of preparation method that is used for VOCs separation degradation membrane, comprises the following steps:

[0034] Step 1, add copper nitrate, manganese nitrate and cerium nitrate in water, stir, obtain thermocatalytic system, wherein, in thermocatalytic system, Cu 2+ :Mn 2+ : Ce 2+ :H 2 The mass ratio of O is: (3-4):(3-4):(1-2):(6-9);

[0035] mixing tetrabutyl titanate and isopropanol in a volume ratio of (1-1.5): (2-3) to obtain a photocatalyst system;

[0036] Step 2, adding the photocatalytic system dropwise into the thermal catalytic system and stirring until a sol is formed to obtain the active component loading liquid;

[0037] Step 3, adding additives and precious metals to the active component loading liquid, stirring vigorously for 5-10 hours at a stirring speed of 400-600r / min; maintaining at room temperature for 5-6 hours to obtain a loaded precursor; One or more of silica sol, pho...

Embodiment 1

[0047] A method for preparing a VOCs separation and degradation film is provided in Example 1, comprising the following steps:

[0048] Step 1. Take quantitative copper nitrate, manganese nitrate and cerium nitrate reagents as required, add copper nitrate, manganese nitrate and cerium nitrate reagents to water, stir to obtain a thermocatalytic system; wherein, in the thermocatalytic system, Cu 2+ :Mn 2+ : Ce 2+ :H 2 The mass ratio of O is: 3:3:1:6; tetrabutyl titanate and isopropanol are mixed in a volume ratio of 1:2 to obtain a photocatalyst system;

[0049] Step 2, adding the photocatalytic system dropwise into the thermal catalytic system and stirring until a sol is formed to obtain the active component loading liquid;

[0050] Step 3. Add silica sol and platinum to the active component loading solution, stir vigorously for 5 hours at a stirring speed of 600r / min; maintain at room temperature for 5-6 hours to obtain a loaded precursor; silica sol and active component T...

Embodiment 2

[0060] A method for preparing a VOCs separation and degradation film is provided in Example 2, comprising the following steps:

[0061] Step 1. Weigh quantitative copper nitrate, manganese nitrate and cerium nitrate reagents as required, add copper nitrate, manganese nitrate and cerium nitrate reagents to water, stir to obtain a thermal catalytic system; wherein, in the thermal catalytic system, Cu 2+ :Mn 2+ : Ce 2+ :H 2 The mass ratio of O is: 4:4:1:8;

[0062] Tetrabutyl titanate and isopropanol are mixed in a volume ratio of 1.2:2.5 to obtain a photocatalyst system;

[0063] Step 2, adding the photocatalytic system dropwise into the thermal catalytic system and stirring until a sol is formed to obtain the active component loading liquid;

[0064] Step 3. Add phosphoric acid and palladium to the active component loading liquid, stir vigorously for 8 hours, and the stirring speed is 500r / min; at room temperature, maintain for 5-6 hours to obtain the loaded precursor; phos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com